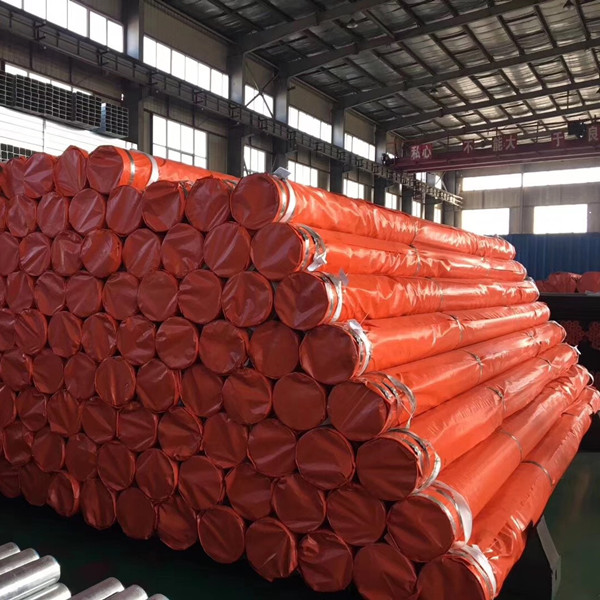

GB 3087 standard seamless boiler alloy steel pipe Low pressure Medium pressure

| Standard: GB/T3087-2008 | Alloy Or Not: seamless carbon steel |

| Grade Group: 10#,20# | Application: Boiler Pipe |

| Thickness: 1 - 100 mm | Surface Treatment: As customer's requirement |

| Outer Diameter(Round): 10 - 1000 mm | Technique: Hot Rolled/ cold drawn |

| Length: Fixed length or random length | Heat treatment: Normalizing |

| Section Shape: Round | Special Pipe: Thick Wall Pipe |

| Place of Origin: China | Usage: Construction, Fluid Transportation, Boiler and Heat Exchanger |

| Certification: ISO9001:2008 | Test: ET/UT |

It is mainly used to make high-quality carbon structural steel, low pressure medium pressure boiler pipe, super heated steam seamless carbon steel pipe

Grade of high-quality carbon structural steel: 10#,20#

| Standard | Grade | Chemical Composition(%) | |||||||

| C | Si | Mn | P | S | Cr | Cu | Ni | ||

| GB3087 | 10 | 0.07~0.13 | 0.17~0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3~0.65 | ≤0.25 | ≤0.30 |

| 20 | 0.17~0.23 | 0.17~0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3~0.65 | ≤0.25 | ≤0.30 | |

| Standard | Steel pipe | Wall thickness | Tensile strength | Yield Strength | Elongation |

| GB3087 | (mm) | (MPa) | (MPa) | % | |

| ≥ | |||||

| 10 | / | 335~475 | 195 | 24 | |

| 20 | <15 | 410~550 | 245 | 20 | |

| ≥15 | 225 | ||||

Permissible deviation of outer diameter of steel tubes

| Type of steel tube | Permissible deviation | ||||||

| Hot rolled (extruded, expanded) steel tube | ± 1.0% D or ± 0.50, take the greater number | ||||||

| Cold drawn (rolled) steel tube | ± 1.0% D or ± 0.30, take the greater number | ||||||

Permissible deviation of the wall thickness of hot rolled (extrusion, expansion) steel tubes

Unit: mm

| Type of steel tube | Outer diameter of steel tube | S / D | Permissible deviation | ||||||

| hot rolled (extruded) steel tube | ≤ 102 | – | ± 12.5 % S or ± 0.40, take the greater number | ||||||

| > 102 | ≤ 0.05 | ± 15% S or ± 0.40, take the greater number | |||||||

| > 0.05 ~ 0.10 | ± 12.5% S or ± 0.40, take the greater number | ||||||||

| > 0.10 | + 12.5% S | ||||||||

| - 10% S | |||||||||

| hot expand steel tube | + 15% S | ||||||||

Permissible deviation of the wall thickness of cold drawn (rolled) steel tubes

Unit: mm

| Type of steel tube | Wall thickness | Permissible deviation | ||||||

| Cold drawn (rolled) steel tube | ≤ 3 | 15 - 10 % S or ± 0.15, take the greater number | ||||||

| > 3 | + 12.5% S | |||||||

| - 10% S | ||||||||

Flattening test

Steel tubes with an outer diameter greater than 22 mm and up to 400 mm, and wall thickness greater than 10 mm should undergo the flattening test. After the samples are flattened

Bending test

Steel tubes with an outer diameter not greater than 22 mm should undergo the bending test. The bending angle is 90o . The bending radius is 6 times the outer diameter of the steel tube.After bending the sample, no fissures or cracks are permitted to appear on the sample.

Macroscopic examination

For steel tubes directly made by continuously cast billets or steel ingots, the supplying party should guarantee that there are no white spots, impurities, sub-surface air bubbles, skull patches or layering on the cross-sectional acid pickled macroscopic tissue of the billet or steel tube.

Non-destructive inspection

According to the demanding party’s request, which is then negotiated between the supplying and demanding parties and indicated in the agreement, ultrasonic flaw detection may be individually performed for steel tubes. The longitudinal manual defect of the reference sample tube should meet the requirements for post-inspection acceptance grade C8 specified in GB/T 5777-1996.