100% Original 15crmo Alloy Steel Pipe - Overview of Boiler pipe – Sanonpipe

100% Original 15crmo Alloy Steel Pipe - Overview of Boiler pipe – Sanonpipe Detail:

Grade:

|

Seamless steel tubes for high / low and medium pressure boilers |

10.20 etc. |

GB3087 |

High qualuty carbon structural seamless ateel pipes for manufacturing of different kinds of low and medium pressure boilers. |

|

SA106B, SA106C |

ASME SA106 |

||

|

SA179/ SA192/ SA210A1, SA210C/ T11, T12, T22, |

ASME SA179/192/210/213 |

||

|

P11, P12, P22, P23, P36, P91, P92 |

ASME SA335 |

||

|

ST35.8, ST45.8, 15Mo3, 13CrMo44, 10CrMo910 |

DIN17175 |

||

|

P195GH, P235GH, P265GH, 16Mo3 |

EN10216-2 |

||

|

20G, 20MnG, 25MnG, 15CrMoG, 12Cr1MoVG, 12Cr2MoG |

GB5310 |

Note:Other Size Can Also Be Provided After Consuliting With Customers

|

GB5310-2008 Chemical Component |

||||||||||||||||||||||

|

no |

grade |

Chemical Component % |

Mechanical Property |

|||||||||||||||||||

|

|

|

C |

Si |

Mn |

Cr |

Mo |

V |

Ti |

B |

Ni |

Alt |

Cu |

Nb |

N |

W |

P |

S |

Tensile |

Yield |

Extend |

Impect (J) |

handness |

|

1 |

20G |

0.17- |

0.17- |

0.35- |

≤ |

≤ |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

410- |

≥ |

24/22% |

40/27 |

— |

|

2 |

20MnG |

0.17- |

0.17- |

0.70- |

≤ |

≤ |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

415- |

≥ |

22/20% |

40/27 |

— |

|

3 |

25MnG |

0.22- |

0.17- |

0.70- |

≤ |

≤ |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

485- |

≥ |

20/18% |

40/27 |

— |

|

4 |

15MoG |

0.12- |

0.17- |

0.40- |

≤ |

0.25- |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

450- |

≥ |

22/20% |

40/27 |

— |

|

6 |

12CrMoG |

0.08- |

0.17- |

0.40- |

0.40- |

0.40- |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

410- |

≥ |

21/19% |

40/27 |

— |

|

7 |

15CrMoG |

0.12- |

0.17- |

0.40- |

0.80- |

0.40- |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

440- |

≥ |

21/19% |

40/27 |

— |

|

8 |

12Cr2MoG |

0.08- |

≤ |

0.40- |

2.00- |

0.90- |

≤ |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

450- |

≥ |

22/20% |

40/27 |

— |

|

9 |

12Cr1MoVG |

0.08- |

0.17- |

0.40- |

0.90- |

0.25- |

0.15- |

— |

— |

≤ |

— |

≤ |

— |

— |

— |

≤ |

≤ |

470- |

≥ |

21/19% |

40/27 |

— |

|

10 |

12Cr2MoWVTiB |

0.08- |

0.45- |

0.45- |

1.60- |

0.50- |

0.28- |

0.08- |

0.002- |

≤ |

— |

≤ |

— |

— |

0.30- |

≤ |

≤ |

540- |

≥ |

18/-% |

40/- |

— |

|

11 |

10Cr9Mo1VNbN |

0.08- |

0.20- |

0.30- |

8.00- |

0.85- |

0.18- |

≤ |

— |

≤ |

≤ |

≤ |

0.06- |

0.030- |

— |

≤ |

≤ |

≥ |

≥ |

20/16% |

40/27 |

≤ |

|

12 |

10Cr9MoW2VNbBN |

0.07- |

≤ |

0.30- |

8.50- |

0.30- |

0.15- |

≤ |

0.0010- |

≤ |

≤ |

≤ |

0.40- |

0.030- |

1.50- |

≤ |

≤ |

≥ |

≥ |

20/16% |

40/27 |

≤ |

note:Alt is holo-al content 2 grade 08Cr18Ni11NbFG of “FG” is mean fine grain,a. no special request, can not add other chemical compinent b.grade 20G of Alt ≤ 0.015%, no working request, but should be showing on MTC

Standard:

ASTM

Standard2:

ASTM A213-2001, ASTM A213M-2001, ASTM A335-2006, ASTM A672-2006, ASTM

A789-2001, ASTM A789M-2001

Grade Group:

A53-A369

Grade:

A335 P1, A335 P11, A335 P12, A335 P5, A335 P9, A335 P91, A335 P92

Section Shape:

Round

Outer Diameter(Round):

6 – 914mm

Place of Origin:

Hengyang Valin Steel Tube Co.,Ltd

Hubei Xinyegang Steel Co., Ltd

Daye Special Steel Co., Ltd,

Yangzhou Chengde Steel Pipe Co., Ltd.

Baosteel

Application:

Boiler Pipe

Thickness:

1 – 80mm

Surface Treatment:

Oil

Certification:

ISO

CE

IBR

EN10204-2004 type3.2

BV/SGS/TUV inspection report

Technique:

Cold Drawn

hot rolled/rolling

Hot-expanded/expanding

Alloy Or Not:

Alloy

Special Pipe:

boiler tubes

Product name:

A335 P11 Alloy Steel Pipe for boiler

A335 P12 Alloy Steel Pipe for boiler

A335 P5 Alloy Steel Pipe for boiler

A335 P9 Alloy Steel Pipe for boiler

A335 P91 Alloy Steel Pipe for boiler

A335 P92 Alloy Steel Pipe for boiler

Keywords:

A335 P11 Alloy Steel Pipe

A335 P12 Alloy Steel Pipe

A335 P5 Alloy Steel Pipe

A335 P9 Alloy Steel Pipe

A335 P91 Alloy Steel Pipe

A335 P92 Alloy Steel Pipe

Brand Name:

SANON PIPE

BAOSTEEL

TPCO

DAYE PIPES

CHENGDE PIPE

VALIN PIPE

End protector:

Plain

Beveled

Type:

SMLS

Length:

5-12m

MTC:

En10204.3.2B

Heat treatment:

Yes

Secondary Or Not:

new

Non-secondary

Supply Ability

2000 Tons Per Month A335 P11 alloy steel pipe

2000 Tons Per Month A335 P12 alloy steel pipe

2000 Tons Per Month A335 P5 alloy steel pipe

2000 Tons Per Month A335 P9 alloy steel pipe

2000 Tons Per Month A335 P91 alloy steel pipe

2000 Tons Per Month A335 P92 alloy steel pipe

Packaging & Delivery

Packaging Details

A335 p22 Alloy Steel Pipe for boiler packaging:In bundles and in strong wooden box

Port

Shanghai

Tianjin

Lead Time

6-8 weeks

Payment:

LC

TT

D/P

AS DISCUSSED

QUALITY CONTROL

1~ Incoming Raw Material Inspection

2~ Raw Material Segregation to avoid steel grade mix-up

3~ Heating and Hammering End for Cold Drawing

4~ Cold Drawing and Cold Rolling, on line inspection

5~ Heat Treatment, +A, +SRA, +LC, +N, Q+T

6~ Straightening-Cutting to specified length-Finished Measuring Inspection

7~Machanical Testing in own labs with Tensile Strength, Yield Strength, Elongation, Hardness, Impact, Mictrostruture etc

8~ Packing and Stocking.

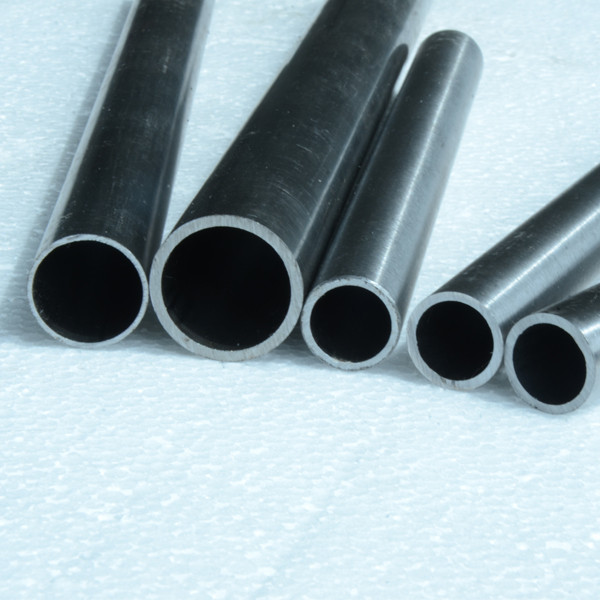

Product detail pictures:

Related Product Guide:

High-quality comes 1st; support is foremost; business is cooperation" is our small business philosophy which is regularly observed and pursued by our organization for 100% Original 15crmo Alloy Steel Pipe - Overview of Boiler pipe – Sanonpipe , The product will supply to all over the world, such as: Doha , Barbados , Portugal , For many years, we have adhered to the principle of customer oriented, quality based, excellence pursuing, mutual benefit sharing. We hope, with great sincerity and good will, to have the honor to help with your further market.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.