Factory Promotional Wall Thickness Alloy Steel Pipe - Seamless, welded and hot-dip galvanized pipe – Sanonpipe

Factory Promotional Wall Thickness Alloy Steel Pipe - Seamless, welded and hot-dip galvanized pipe – Sanonpipe Detail:

Overview

Application

It Is Mainly Used for force and pressure parts, and for general purpose steam, water, gas and air pipes.

Main Grade

GR.A, GR.B

Chemical Component

|

Grade |

Component %,≤ | ||||||||

| C | Mn | P | S |

CuA |

NiA |

CrA |

MoA | VA | |

| S type(seamless pipe) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| E type(Resistance welded pipe) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| F type(Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

A The sum of these five elements must not be greater than 1.00%。

B For every 0.01% decrease in the maximum carbon content, the maximum manganese content is allowed to increase by 0.06%, but the maximum cannot exceed 1.35%.

C Each 0.01% decrease in the maximum carbon content will allow the maximum manganese content to increase by 0.06%, but the maximum must not exceed 1.65%.

Mechanical Property

| item | GR.A | GR.B |

|

tensile strength, ≥, psi [MPa] Yield Strength, ≥, psi [MPa] Gauge 2in.or 50mm elongation |

48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A The minimum elongation of gauge length 2in. (50mm) shall be determined by the following formula:

e=625000(1940)A0.2/U0.9

e = the minimum elongation of the gauge 2in. (50mm), the percentage rounded to the nearest 0.5%;

A = Calculated according to the specified outer diameter of the nominal tube or the nominal width of the tensile sample and its specified wall thickness, and rounded to the nearest cross-sectional area of the tensile sample of 0.01 in.2 (1 mm2), and It is compared with 0.75in.2 (500mm2), whichever is smaller.

U = specified minimum tensile strength, psi (MPa).

B For various combinations of different sizes of tensile test specimens and prescribed minimum tensile strength, the required minimum elongation is shown in Table X4.1 or Table X4.2, according to its applicability.

Test Requirement

Tensile test, bending test, hydrostatic test, nondestructive electrical test of welds.

Supply Ability

Supply Ability: 2000 Tons Per Month Per Grade Of ASTM A53/A53M-2012 Steel Pipe

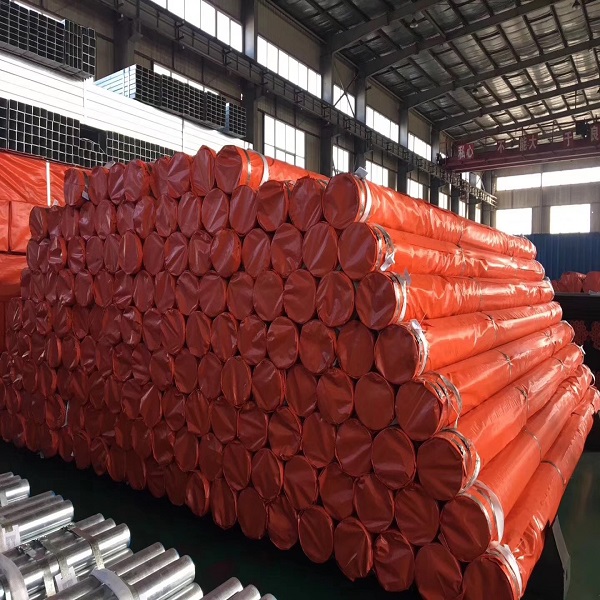

Packaging

In Bundles And In Strong Wooden Box

Delivery

7-14 days if in stock, 30-45 days to produce

Payment

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight

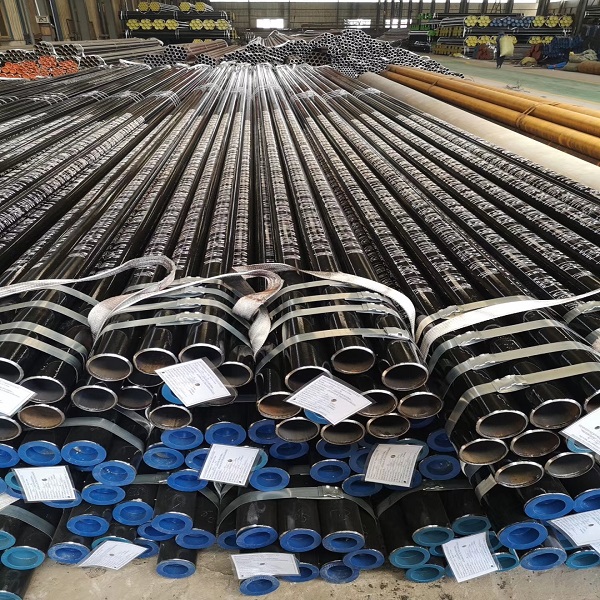

Product Detail

Boiler Tube

GB/T 8162-2008

ASTM A519-2006

BS EN10210-1-2006

ASTM A53/A53M-2012

GB9948-2006

GB6479-2013

GB/T 17396-2009

Product detail pictures:

Related Product Guide:

We can normally fulfill our respected consumers with our great excellent, great value and good provider due to we're much more specialist and extra hard-working and do it in cost-effective way for Factory Promotional Wall Thickness Alloy Steel Pipe - Seamless, welded and hot-dip galvanized pipe – Sanonpipe , The product will supply to all over the world, such as: South Africa , Peru , Hamburg , To achieve reciprocal advantages, our company is widely boosting our tactics of globalization in terms of communication with overseas customers, fast delivery, the best quality and long-term cooperation. Our company upholds the spirit of "innovation, harmony, team work and sharing, trails, pragmatic progress". Give us a chance and we will prove our capability. With your kind help, we believe that we can create a bright future with you together.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!