Featured Products

-

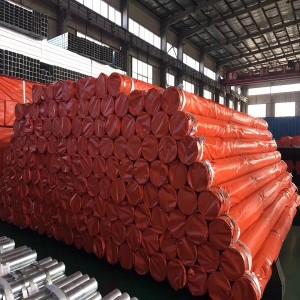

API5CT Oil Pipeline

API5CT Oil Casing Is Mainly Used To Transport Oil, Natural Gas, Gas, Water And Other Liquids And Gases.

It Can Be Divided Into Seamless Steel Pipe And Welded Steel Pipe. Welded Steel Pipe Mainly Refers To Straight Seam Steel Pipe, And Large-Caliber Petroleum Casing Is Generally Straight Seam Submerged Arc Welding Steel Pipe. The Main Application Countries Of This Product Are Mainly Distributed In The Middle East, Europe And America. Api5ct Casing Can Be Divided Into R-1, R-2 And R-3 Specifications Depending On Length. The Main Materials Are B, X42, X46, X56, X65, X70 And So On. In Extreme High Temperature And High Pressure Environment, Petroleum Casing Material Pipeline Has Its Own Unique Natural Advantages. Api5ct Oil Casing From Raw Materials To Products Before Delivery Of Flattening Test, Tensile Test, Impact Test, Tensile Test And Other Related Testing.

-

Seamless Steel Tubes For Petroleum Cracking,GB9948-2006,Sanon Pipe

As we all know, fuel oil is refined from petroleum. The price of petroleum is rising these years, and the cost of driving is getting higher and higher. In the process of extracting oil, many pipelines need to be installed.

Here’s a look at the pipeline:

Tubing (GB9948-88) is a seamless steel tube suitable for furnace tube, heat exchanger and pipeline in petroleum refinery.

Steel pipe for geological drilling (YB235-70) is used for core drilling by geological department, which can be divided into drill pipe, drill collar, core pipe, casing pipe and precipitation pipe according to its use.

Oil pipe is a kind of long steel with hollow section and no joint around, while petroleum cracking pipe is a kind of economic section steel.

Tubing is widely used in the manufacture of structural and mechanical parts such as oil drill pipes, car drive shafts, bicycle frames and steel scaffolding for moving pictures in construction. Using petroleum cracking tube to manufacture ring parts can improve material utilization rate, simplify manufacturing process, save material and processing time, such as rolling bearing ring, jack sleeve, etc., has been widely used to manufacture steel pipe. Petroleum cracking tube or a variety of conventional weapons indispensable material, barrel, barrel and so on to petroleum cracking tube to manufacture. Petroleum cracking pipe can be divided into round pipe and special-shaped pipe according to the shape of cross-sectional area. Since the area of petroleum cracking pipe is the largest with the same perimeter, more fluid can be transported with circular pipe.

High quality carbon structural steel grades are 20g,

20mng and 25mng;Alloy structural steel grades: 15mog, 20mog, 12crmog,15CrMoG、12Cr2MoG、12CrMoVG,etc

-

Seamless Medium carbon steel boiler and Superheat tubes ASTM A210 standard

SA210 High Pressure Alloy Pipe Implementation Standard ASTM A210—– ASME SA210- American Society Of Mechanical Engineers Standard.

Suitable For Use In Boiler Pipe And Flue Pipe, Including Safety End, Vault And Support Pipe And Superheater Pipe With Minimum Wall Thickness Seamless Medium Carbon Steel Pipe.

Main Production Of High Pressure Alloy Pipe Grades: A210A1, A210C And So On.

-

Seamless steel tubes for high-pressure boilers in GB/T5310-2017 Standard

High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipe for high-pressure and above steam boiler pipes in GB/T5310-2007 standard. Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 20MoG, 12CrMoG, etc

-

GB/T5310-2017 Seamless tube for high pressure boiler

High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipe for high-pressure and above steam boiler pipes in GB/T5310-2007 standard. Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 20MoG, 12CrMoG, etc

-

seamless alloy steel pipe ASTM A335 P9

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous.

ASTM A335 P9 is an alloy steel seamless ferritic high temperature pipe of American standard. Alloy tube is a kind of seamless steel tube, its performance is much higher than the general seamless steel tube, because this kind of steel tube contains more C, the performance is less than the ordinary seamless steel tube, so the alloy tube is widely used in petroleum, aerospace, chemical, electric power, boiler, military and other industries.

A335 P9 is a high temperature chromium-molybdenum alloy heat resistant steel produced according to the American standard. Because of its excellent oxidation resistance, high temperature strength and sulfide corrosion resistance, it is widely used in high temperature and high pressure inflammable and explosive pipelines of petroleum refining plants, especially direct heat pipe of heating furnace, medium temperature can reach 550~600℃.

Corresponding domestic alloy steel :1Cr5Mo GB 9948-2006 “Seamless Steel Pipe Standard for Petroleum Cracking”

-

seamless alloy steel pipe ASTM A335 P5

ASTM A335 P5 is an alloy steel seamless ferritic high temperature pipe of American standard. Alloy tube is a kind of seamless steel tube, its performance is much higher than the general seamless steel tube, because this kind of steel tube contains more C, the performance is less than the ordinary seamless steel tube, so the alloy tube is widely used in petroleum, aerospace, chemical, electric power, boiler, military and other industries.

Alloy Steel pipe contains substantial quantities of elements other than carbon such as nickel, chromium, silicon, manganese, tungsten, molybdenum, vanadium and limited amounts of other commonly accepted elements such as manganese, sulfur, silicon, and phosphorous

Corresponding domestic alloy steel :1Cr5Mo GB 9948-2006 “Seamless Steel Pipe Standard for Petroleum Cracking”

-

![[Copy] GB/T5310-2017 Seamless tube for high pressure boiler](http://www.sanonpipe.com/uploads/8d9d4c2f9-300x296.jpg)

[Copy] GB/T5310-2017 Seamless tube for high pressure boiler

High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipe for high-pressure and above steam boiler pipes in GB/T5310-2017 standard.The steel pipe is required to have high endurance strength, high anti-oxidation and corrosion performance, and good structural stability.Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 20MoG, 12CrMoG, etc

-

![[Copy] Seamless Steel Tubes For Petroleum Cracking,GB9948-2006,Sanon Pipe](http://www.sanonpipe.com/uploads/ff652257-300x300.jpg)

[Copy] Seamless Steel Tubes For Petroleum Cracking,GB9948-2006,Sanon Pipe

Seamless steel tubes for petroleum cracking,sered as for fumace tubes,heat exchange tubes and

pipelines in petroleum and refinery plants.High quality carbon structural steel grades are 20g,

20mng and 25mng;Alloy structural steel grades: 15mog, 20mog, 12crmog,15CrMoG、12Cr2MoG、12CrMoVG,etc

The use temperature of GB9948 seamless steel pipe is below 450℃,and the domestic pipe is mainly made of No.10 and No.20 carbon bonded dteel hot rolled pipe or cold drawn pipe.

GB9948 seamless steel pipe is often used in high temperature and high pressure conditions the pipe under the action of high temperature flue gas and water vapor,ox oxidation and corrosion. The steel pipe is required to have high durable strength,high oxidation corrosion resistance and good microstructure stability.

-

Seamless steel tubes for high-pressure boilers ASTM A335/A335M-2018

Main material: P11 P12 P22 P5 P9 P23 P91 P92, production process: hot rolling, cold drawing.

P2 P12: manufactured by coarse-grain melting process, heat treatment requirements, see the standard for details.

Testing: Tensile, bending, hardness, water pressure test, non-destructive testing (ultrasonic, eddy current)

-

-

High quality carbon structural steel, alloy structural steel and stainless heat resistant steel high pressure seamless pipe for steam boiler pipelines under high pressure and above pressure

Manufacturing method:

(1) General GB9948 seamless steel pipe temperature is below 450℃, domestic pipe is mainly made of no. 10, 20 carbon bonded steel hot rolled pipe or cold drawn pipe.

②GB9948 seamless steel pipe is often used in high temperature and high pressure conditions, the pipe under the action of high temperature flue gas and water vapor, oxidation and corrosion will occur.The steel pipe is required to have high durable strength, high oxidation corrosion resistance and good microstructure stability.

(2) use:

(1) General GB9948 seamless steel pipe is mainly used to manufacture water-cooled wall pipe, boiling water pipe, superheated steam pipe, locomotive boiler superheated steam pipe, large and small smoke pipe and arch brick pipe.

②GB9948 seamless steel tube is mainly used to manufacture superheater tube, reheater tube, pipe, main steam pipe and so on of high pressure and ultra-high pressure boiler.

GB9948 seamless steel tube according to the high temperature performance is divided into general boiler tube and high pressure boiler tube.Whether general boiler tube or high pressure boiler tube can be divided into various steel tubes according to different requirements of its use.

Specifications and appearance quality

(1)GB3087-2008 “Seamless Steel pipe for Low and medium pressure boiler” provisions.Specifications of steel tubes for various structural boilers, diameters 10 ~ 426mm, 43 kinds in total.There are 29 kinds of wall thickness from 1.5 mm to 26mm.However, the outer diameter and wall thickness of superheated steam pipe, large smoke pipe, small smoke pipe and arch brick pipe used in locomotive boiler are stipulated otherwise.

(2)GB5310-2008 “Seamless Steel Tube for High pressure Boiler” hot rolled pipe diameter 22 ~ 530mm, wall thickness 20 ~ 70mm.Cold drawn (cold rolled) tube diameter 10 ~ 108mm, wall thickness 2.0 ~ 13.0mm.

(3)GB3087-2008 “seamless steel tube for low and medium pressure boiler” and GB5310-2008 “seamless steel tube for high pressure boiler” provisions.Appearance quality: cracks, folding, rolling, scarring, separation and wrinkles are not allowed on the inner and outer surface of the steel pipe.These defects should be eliminated completely.The clearance depth shall not exceed the negative deviation of the nominal wall thickness, and the actual wall thickness at the clearance shall not be less than the minimum allowable wall thickness.

-

Seamless steel tubes and seamless alloy steel tubes GB5310 P11 P5 P9 ASTM A53/A53M-2012

Seamless steel pipes and welded steel pipes for general purpose steam, water, gas and air lines in ASTM A53/A53M-2012 Standard.

-

Seamless Steel Tubes and Pipes for High-Pressure Boilers (Carbon ,Alloy)

Seamless steel tube used in high pressure boiler is a kind of boiler tube, which has strict requirements on the steel grade and technology used in the manufacture of steel tube.High-pressure boiler pipe is often used in high temperature and high pressure conditions, the pipe in high temperature flue gas and water vapor, oxidation and corrosion.The steel pipe is required to have high durable strength, high oxidation corrosion resistance and good microstructure stability.High pressure boiler tube is mainly used to manufacture superheater tube, reheater tube, conduit pipe, main steam pipe and so on of high pressure and ultra high pressure boiler.

The main materials are :ASTM/ASMEA-1, B, T22 /T22,T2 / P2 and so on, the working temperature is 450℃-650℃

-

A106 GR.B Seamless Steel Pipe

High-Quality Carbon Steel Heat-Resistant Seamless Pipe For Construction Structure and Mechanical Strucutre. Material is 20# A106 GR.B , high quality carbon steel, it is a common steel pipe material.

-

API 5L Carbon Seamless Steel Line Pipe

Seamless pipeline used for high quality transport the oil, steam and water drawn from the ground to the oil and gas industry enterprises through the pipeline

API5L standard is suitable for seamless pipe used in oil and gas industry pipeline transportation system.Two product specification levels are included (PSL1 and

PSL2)

1) Standard: API5L ASTM ASME B36.10DIN

2) material: API5LGr. B A106Gr. B, A105Gr. B, A53Gr. B, A243WPB, etc.

3) Outside diameter: 13.7mm-1219.8mm

4) Wall thickness: 2.11mm-100mm

5) Length: 5.8 m, 6 m, 11.6 m, 11.8 m, 12 m

6) Packaging: spray paint, beveling, pipe cap, galvanized steel belt bundled yellow lifting belt integrated woven bag packaging.

7) API 5Lgr. B Pipeline steel seamless steel tubes.

-

High Quality ASTM A192 Seamless Carbon Steel Boiler Tube/Pipe with ASTM A192 China Factory

Standards:

ASME SA106—High temperature seamless carbon steel tubeASME SA179—Seamless cold drawn low carbon steel pipe for heat exchanger and condenser

ASME SA192—Seamless carbon steel boiler tube for high pressure

ASME SA210—Seamless Medium Carbon Steel Pipe for Boilers and Superheaters

ASME SA213—Seamless ferritic and austenitic alloy steel pipes for boilers, superheaters and heat exchangers

ASME SA335—Seamless ferritic alloy steel nominal tube for high temperature

DIN17175 — Seamless steel pipe made of heat-resistant steel

EN10216-2 —Unalloyed steel and alloy steel pipes with specified high temperature properties

GB5310 —Seamless steel pipe for high pressure boiler

GB3087 —Seamless steel pipe for low and medium pressure boilers

-

![[Copy] GB 3087 standard seamless boiler alloy steel pipe Low pressure Medium pressure](http://www.sanonpipe.com/uploads/94fbbe30-300x300.jpg)

[Copy] GB 3087 standard seamless boiler alloy steel pipe Low pressure Medium pressure

low pressure Medium pressure boiler pipe super heated steam pipe high quality seamless carbon steel pipe

Mainly for India market with IBR certification

GB 3087-2008″seamless steel tube for low and medium pressure boiler” and GB5310-2008″seamless steel tube for high pressure boiler” provisions. Appearance quality: cracks,folding,rolling,scarring,separation and wrinkles are not allowde on the inner and outer surface of the steel pipe.These defects should be eliminated completely.The clearance depth shall not exceed the negative deviation of the nominal wall thickness,and the actual wall thickness at the clearance shall not be less than the minimum allowable wall thickness.

-

Specification for Casing and Tubing API SPECIFICATION 5CT NINTH EDITION-2012

Api5ct oil casing is mainly used to transport oil, natural gas, gas, water and other liquids and gases,It can be divided into seamless steel pipe and welded steel pipe. Welded steel pipe mainly refers to longitudinal welded steel pipe. Conduit, surface casing, technical casing, reservoir casing

-

![[Copy] 20# seamless pipe](http://www.sanonpipe.com/uploads/P91231-102354_副本1-300x225.jpg)

[Copy] 20# seamless pipe

General seamless steel pipe: it is made of 10, 20, 30, 35, 45 and other high-quality carbon bonded steel 16Mn, 5MnV and other low alloy structural steel or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steel hot rolled or cold rolled.10, 20 and other low carbon steel manufacturing seamless pipe is mainly used for fluid pipeline.45, 40Cr and other medium carbon steel made of seamless pipe to manufacture mechanical parts, such as cars, tractors stressed parts.The general use of seamless steel pipe to ensure the strength and flattening test.Hot rolled steel pipes are delivered in hot rolled or heat treated condition.Cold rolled delivery is heat – treated.High-Quality Carbon Steel Heat-Resistant Seamless Pipe For Construction Structure and Mechanical Strucutre. Material is 20#, high quality carbon steel, it is a common steel pipe material.High-Quality Carbon Steel Heat-Resistant Seamless Pipe For Construction Structure And Mechanical Strucutre. Material Is 20#, High Quality Carbon Steel, It Is A Common Steel Pipe Material.

-

![[Copy] Seamless tube for high pressure boiler GB/T5310-2017](http://www.sanonpipe.com/uploads/8d9d4c2f9-300x296.jpg)

[Copy] Seamless tube for high pressure boiler GB/T5310-2017

Seamless steel tubes for high pressure boilers,High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel and above steam boiler pipes in GB/T5310-2007 standard. Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 25MnG, 12CrMoG,15MoG,20MoG,15CrMoG,12Cr2MoG,12Cr1MoVG, etc

-

China Manufacturer for China Factory Seamless Hollow Section Alloy Steel Pipe Tube ASTM A335 Heat-Resisting Gas Air Boiler Petroleum Cracking

ASTM A335 standard high Temperature boiler pipe seamless alloy pipe with IBR certifiaction

Seamless alloy pipe for boiler ,heat exchanger etc industry

-

High Quality China Seamless Alloy Steel Pipe A335 Standard P2 P5 P9 P11 P12 P22

High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipe for high-pressure and above steam boiler pipes in GB/T5310-2007 standard. Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 20MoG, 12CrMoG, etc

-

Rapid Delivery for China Heavy Thickness Alloy Seamless Steel Pipe for High Pressure Boiler

High-quality carbon structural steel, alloy structural steel, and stainless heat-resistant steel seamless steel pipe for high-pressure and above steam boiler pipes in GB/T5310-2007 standard. Material mainly is Cr-Mo alloy and Mn Alloy, Such as 20G, 20MnG, 20MoG, 12CrMoG, etc