Galvanized Steel Pipe

Our company specializes in seamless steel pipe export galvanized pipe, Seamless Galvanized Pipe, SMLS galvanized pipe, WELDED galvanized pipe.

What is the difference between hot galvaninzed and cold galvanized?

Hot-dip galvanizing and cold galvanized the difference:

1. Galvanizing, also known as hot dip galvanized, he is the ingot melted at high temperatures, a number of supplementary material in place, then dipped galvanized metal structure slot, the metal component on a layer of zinc coating . The advantages of hot-dip galvanizing corrosion of his ability, adhesion and hardness of zinc coating is better

“Cold plated” or “plating”, ie the zinc salt solution by electrolysis, to the plating on the coating, generally do not have heating, small amount of zinc, the wet environment is very easy to fall off.

2. Hot dip galvanized (galvanizing)

Hot-dip galvanizing is a chemical treatment, is the electrochemical reaction.

Cold galvanizing is the physical address, just brush the surface layer of zinc, the zinc layer is easy to fall off. Construction in the use of hot dip galvanizing.

Continuous hot dip galvanizing process: steel → heating → cooling to the temperature galvanized galvanized → cooling →

Cold galvanized zinc is only 10-50g/m2, its own corrosion resistance than hot dip galvanized a lot of difference. Galvanized by a relatively cheaper price.

Hot dip galvanized steel body is hot dip galvanized surface under the condition of its adhesion strong, not easy to fall off, although there hot dip galvanized pipe corrosion phenomenon, but in a very long period to meet technical, health requirements.

3. Technological differences

First of all, is the difference between process: hot-dip galvanizing is the workpiece degreasing, pickling, dipping, drying liquid immersion in molten zinc certain period of time, can be raised.

Also known as electro-galvanized cold galvanizing, is to use electrolysis devices work piece through the degreasing, pickling ingredients post into the zinc salt solution, and connect the anode electrolysis equipment; in place across parts of zinc plate connected to the electrolysis equipment positive, power on, use of current from the cathode to the anode of the directional movement of the workpiece will be deposited in a layer of zinc.

Zinc finished the difference: no cold galvanized hot-dip galvanizing delicate bright appearance, but the thickness of zinc coating of cold galvanizing aspects of hot-dip galvanizing is a few times. Galvanized corrosion resistance is also several times.

Overview

Application

It Is Mainly Used for force and pressure parts, and for general purpose steam, water, gas and air pipes.

Main Grade

GR.A, GR.B

Chemical Component

|

Grade |

Component %,≤ | ||||||||

| C | Mn | P | S |

CuA |

NiA |

CrA |

MoA | VA | |

| S type(seamless pipe) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| E type(Resistance welded pipe) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

| F type(Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 |

0.40 |

0.40 |

0.40 |

0.15 | 0.08 |

A The sum of these five elements must not be greater than 1.00%。

B For every 0.01% decrease in the maximum carbon content, the maximum manganese content is allowed to increase by 0.06%, but the maximum cannot exceed 1.35%.

C Each 0.01% decrease in the maximum carbon content will allow the maximum manganese content to increase by 0.06%, but the maximum must not exceed 1.65%.

Mechanical Property

| item | GR.A | GR.B |

|

tensile strength, ≥, psi [MPa] Yield Strength, ≥, psi [MPa] Gauge 2in.or 50mm elongation |

48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A The minimum elongation of gauge length 2in. (50mm) shall be determined by the following formula:

e=625000(1940)A0.2/U0.9

e = the minimum elongation of the gauge 2in. (50mm), the percentage rounded to the nearest 0.5%;

A = Calculated according to the specified outer diameter of the nominal tube or the nominal width of the tensile sample and its specified wall thickness, and rounded to the nearest cross-sectional area of the tensile sample of 0.01 in.2 (1 mm2), and It is compared with 0.75in.2 (500mm2), whichever is smaller.

U = specified minimum tensile strength, psi (MPa).

B For various combinations of different sizes of tensile test specimens and prescribed minimum tensile strength, the required minimum elongation is shown in Table X4.1 or Table X4.2, according to its applicability.

Test Requirement

Tensile test, bending test, hydrostatic test, nondestructive electrical test of welds.

Supply Ability

Supply Ability: 2000 Tons Per Month Per Grade Of ASTM A53/A53M-2012 Steel Pipe

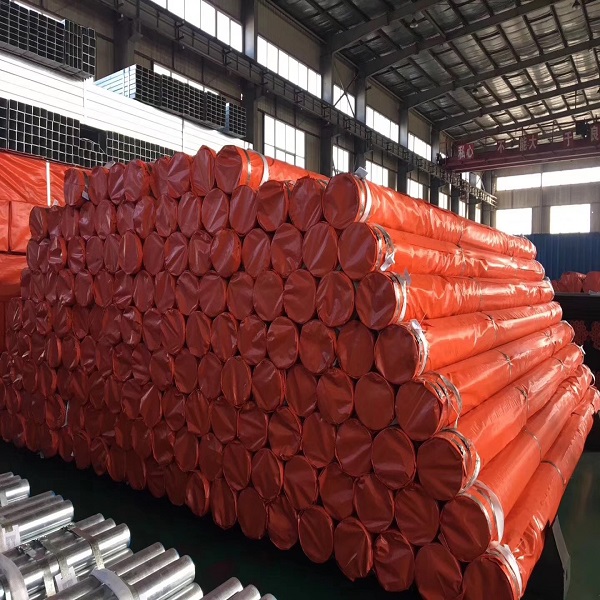

Packaging

In Bundles And In Strong Wooden Box

Delivery

7-14 days if in stock, 30-45 days to produce

Payment

30% depsoit, 70% L/C or B/L copy or 100% L/C at sight