Mummunan ƙwayar ƙwayar ƙwayar ƙwayar ƙarfe mara ƙarfe: bututun ƙarfe mara nauyi da aka yi da Ingilishi mai ƙarfi Bilet ta hanyar turawa mai laushi, sanyi yi birgima. Abubuwan da aka yi da ingancin carbon carbon kamar 10,20, 30, 35,45, low alloy karfe mai tsari kamarGoma a, 5mnv ko kadanoy karfe kamar 40cr, 30cmnsi, 45mn2, na 145mnb da zafi mirgine ko sanyi mirgine. Bututun ciki da aka yi da ƙananan carbon mara nauyi kamar 10 da 20 ana amfani da galibi don bututun bayarwa na ruwa.

Yawancin lokaci, tsarin samar da bututun ƙarfe na maraice ya kasu kashi biyu: Tsarin zane da tsarin morling mai zafi. Mai zuwa shine taƙaitaccen bayani game da kwararar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙwayar ƙarfe da ruwan sanyi mai zafi:

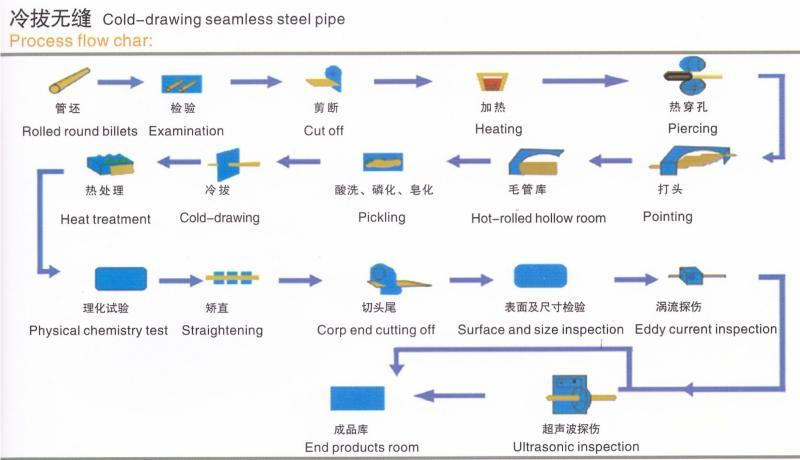

Sanyi-zana (sanyi-birgima) bututu mai laushi tsari da kuma dubawa → tube masara (ba lalatattun abubuwa, na zahiri da sunadarai, benci da sunadarai

Cold-mirgine bututun bututun ƙarfe mara kyau dole ne a fara fuskantar ci gaba da ci gaba da mirgine sau uku, an yi gwaji masu tarin yawa bayan fashewa. Idan babu wani mai amsa crack a farfajiya, dole ne a yanka bututun zagaye ta hanyar kayan yankan kuma a yanka a cikin Billets tare da tsawon kimanin mita ɗaya. Sannan shigar da aikin enaling. Dole ne a shafa wani abu da ruwan acidic. A lokacin zabe, kula da ko akwai babban kumfa a farfajiya. Idan akwai adadin kumfa mai yawa, yana nufin cewa ingancin bututun ba ya cika ka'idodin da suka dace.

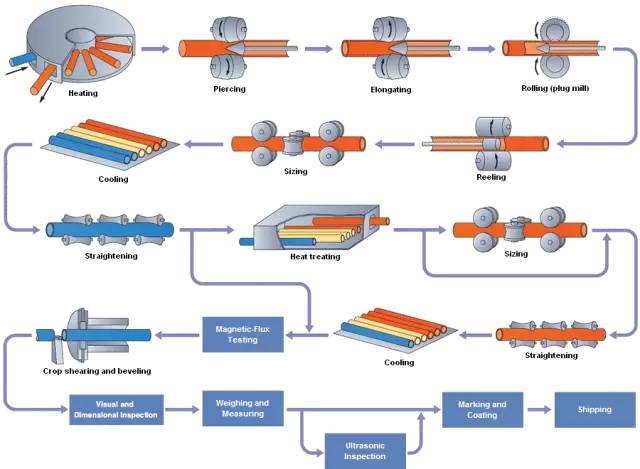

Hot-birgima

Zafi mirgina, kamar yadda sunan ya nuna, yana da babban zazzabi don gyaran birgima, don haka lalata juriya karami ne kuma ana iya samun babban adadin ƙazanta. Isar da jihar-mirgine bututun ƙarfe mara kyau yana da zafi-birgima da zafi-da aka bi da shi kafin bayarwa. Ana cire bututun mai ƙarfi da lahani na saman, a yanka a cikin ƙarshen da ake buƙata, sannan a fara a ƙarshen fuskar ƙarshen bututun mai don dumama. Duk da yake da serchoring, yana juyawa kuma yana motsa gaba gaba. A ƙarƙashin aikin rollers da kai, kogon hankali siffofin a cikin bututu, wanda ake kira da bututun mai wuya. Bayan bututun an cire shi, an aiko shi zuwa injin bututu na atomatik don ci gaba da mirgina, kuma sai an tabbatar da kauri ta matakin da aka shirya don sadad da bukatun allon. Bayan ingantaccen magani mai zafi, ya kamata a gudanar da gwajin da aka yi. Idan diamita mai girman kai ya yi yawa, ya kamata ya daidaita kuma ya gyara, kuma a ƙarshe ya yi kwanto kuma a saka shi cikin ajiya.

Kwatanta tsari na zane mai sanyi da tsari mai zafi: tsari mai sanyi na sanyi sun fi rikitarwa na faranti mai sanyi, amma bayyanar fararen faranti, da kuma lokacin farin ciki na iya zama bakin ciki.

Girman: Motsi na waje na bututun mai zafi ya fi na 32m, da kuma kaurin kauri shine 2.5-200mm. M diamita na sanyi-mirgine bututun karfe na iya zama har zuwa 6mm, kauri mai kauri na iya zuwa 0.2mmm na bango na bakin ciki mirgine ya fi na zafi mirgina.

Bukatar: Kodayake bangon kauri daga bututu mai sanyi, farfajiya yana haske fiye da lokacin farin karfe mai narkewa, kuma diamita ba shi da mai ƙonewa da yawa.

Halin isarwa: An kawo bututun ƙarfe mai zafi a cikin zafi-birgima ko kuma a kula da yanayin zafi, da kuma bututun ƙarfe mai sanyi a cikin yanayin da aka yiwa.

Lokaci: Aug-21-2024