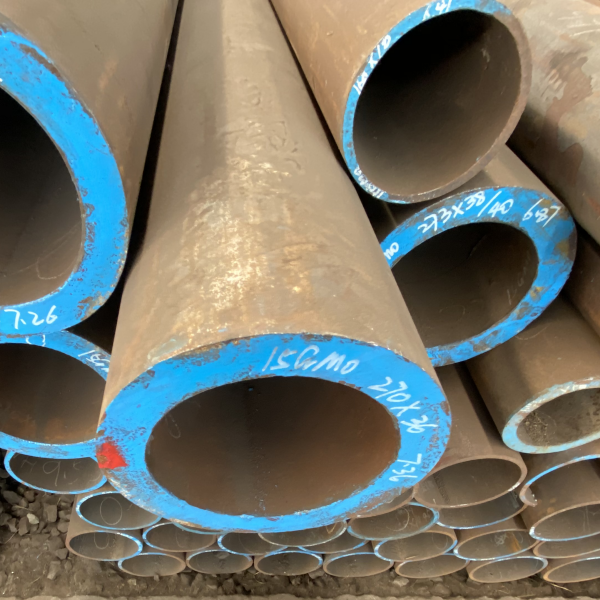

Bread karfe shambo na petrooleum, gb9948-2006, bututun sanon

| Standard:GB9948-2006 | Jiyya mai zafi: Annealing / Normuping / Zuciya |

| Kungiya: 10,12CMO, 15CMO, 07crl9nil0, da sauransu | Diami na waje (zagaye): 10 - 1000 mm |

| Kauri: 1 - 100 mm | Aikace-aikacen: Shafukan musayar zafi |

| Diami na waje (zagaye): 10 - 1000 mm | Jiyya na farfajiya: Kamar yadda ake buƙata na abokin ciniki |

| Tsawon: tsayayyen tsayi ko tsawon lokaci | Dabara: zafi yi birgima |

| Siffar sashe: zagaye | Bututun musamman: bututun bango |

| Wurin Asali: China | Amfani: Haske na musayar bututu |

| Takaddun shaida: ISO9001: 2008 | Gwaji: UT / MT |

Shankunan ƙarfe mara ƙarfe ga ƙwayar ƙwayar cuta na ƙwayar cuta don shubes mai laushi don shubutan wuta, shambo mai canzawa a cikin masana'antar petrochemalicer.

High quality Carbon Tsarin Strades ne 20g, 20mng da 25Mng.

Alloy Tsarin ƙarfe na Motoci: 15Mog, 20mog, 12crmog

15Crmog, 12c22, 12crmovg, da sauransu

Sa na babban carbon carbon karfe: 10 #,20 #

High / dari Carbon Carbon Tsarin Karfe: 20g, 20Mng da 25Mng

Alloy Tsarin Karfe maki: 15Mog, 20mog, 12crogg, 15crmog, 15crmog, 12cf2

| No | Sa | Kayan sunadarai% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| High quality carbon carbon tsarin karfe | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0-05 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0-05 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Alloy Allul | 12crmo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CMO | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12crmo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12crlmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12c2mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.10-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12crui | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Crmont | |||||||||||||

| 12cr9Moi | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Crmont | |||||||||||||

| Bakin ciki mai tsayayya da ƙarfe | 07crl9nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07crl8nillNB | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07crl9Nillti | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4c-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022crl7nil2mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

| A'a | Mai zafi MPA | yawa MPA | Elong bayan rauni a /% | Shork Cire makamashi KV2 / J | Lambar Bratinell | ||

| kash | transver | kash | transver | ||||

| ba kasa da | babu fiye da | ||||||

| 10 | 335~475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410 --50 | 245 | 24 | 22 | 40 | 27 | |

| 12crmo | 410 --60 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CMO | 440~640000 | 295 | 21 | 19 | 40 | 27 | 170 hbw |

| 12crmo | 415-560 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12crlmov | 470~640000 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12c2mo | 450 ~ 600 | 280 | 22 | 20 | 40 | 27 | 163 hbw |

| 12crui | 415~590 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12Crmont | 480~6400000 | 280 | 20 | 18 | 40 | 27 | - |

| 12cr9Moi | 460~6440000 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Crmont | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7crl9nilo | 2520 | 205 | 35 | 187 hbw | |||

| 07crl8nillNB | > 520 | 205 | 35 | - | 187 hbw | ||

| 07crl9Nillti | > 520 | 205 | 35 | - | - | 187 hbw | |

| 022crl7nil2mo2 | > 485 | 170 | 35 | 一 | - | 187 hbw | |

| Don karfe tare da kauri bango ƙasa da 5mm bututu baya yin gwajin wuya | |||||||

Gwajin Hydraulic

Gwajin Hydraulic za a aiwatar da bututun karfe daya bayan daya. Matsakaicin matsin lamba shine 20 MPA. A ƙarƙashin matsin lamba na gwaji, lokacin karuwa ba zai zama ƙasa da 10 s, da kuma raunuka na bututun ƙarfe ba a yarda da shi ba.

Gwaji na gwaji

Za a gudanar da gwajin abinci don bututun karfe tare da diami na waje wanda ya fi girma 22 mm

Gwajin flarr

Babban Kayan Carbon Carbon na Carbon da bakin ciki (zafi-resistant) bututun ƙarfe tare da mm diamita na ba fiye da 86 mm zai zama batun fadada gwaji. Za a gudanar da gwajin foro a zazzabi a daki. Matsalar diamita ta waje ta samfurin bayan samfurin bayan saman Stering shine 60% na fashin zai cika bukatun tebur 7. Babu fasa ko fasa ko fasa; Dangane da bukatun mai nema da lura a cikin kwangilar, ana iya amfani da allon tsarin ƙarfe don fadada gwaji.

Tesontruent Teste

Ganuwa na ƙarfe zai kasance ƙarƙashin gano ƙarancin rashin daidaituwa ta ultrasonic Daya bisa ga ɗayan tanada na GB / t 577-2008. Dangane da bukatun na mai nema, ana iya samun wasu gwaje-gwaje marasa halaka bayan sasantawa tsakanin mai ba da kaya da kuma nuna a kwangilar.

Gwajin Ciniki na Ciniki

Gwajin lalata intergramular za a gudanar da bakin ciki (zafi-resistant) bututun karfe. Hanyar gwaji za ta kasance daidai da tanadin Hanyar Sinanci e a GB / T 4334-2008, da mahalarta lalata tsakani ba bayan gwajin ba.

Bayan tattaunawar tsakanin mai ba da kaya, kuma ya lura a cikin kwantiragin, mai biyanjarta na iya tsara sauran hanyoyin gwajin lalata.

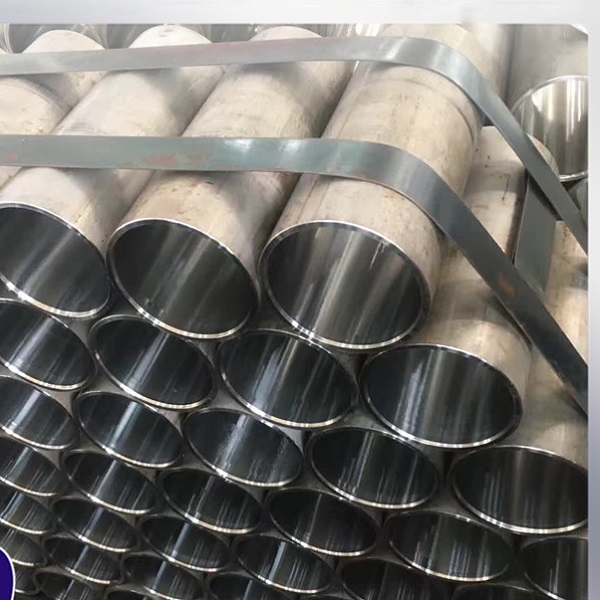

Man, mai petrochemical, mai matsanancin iska, amfani na musamman na tube tukunyar tukunyar ruwa mara kyau.

Sayarwar sunadarai

| iri | Kayan sunadarai (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| 15CMO | 0.12 ~ 0.18 | 0.40 ~ 0.70 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Dukiyar inji

| iri | Mai zafi MPA | yawa MPA | Elongation (%) |

| 15CMO | 440 ~ 640 | 295 | 22 |