Seamless steel yeeb nkab cov khoom: Seamless steel yeeb nkab yog ua los ntawm cov hlau ingot los yog cov raj raj raj billet, thiab ces kub dov, txias dov lossis dov los yog txias txav. Cov khoom siv feem ntau ua los ntawm cov hlau zoo li cov roj carbon hlau xws li 10,20, 30, 35,45, tsawg alloter qauv hlau xws li16mn, 5mnv lossis alloy steel xws li 40cr, 30crmnsi, 45mn2, 40mnb los ntawm kub dov lossis dov kub lossis txias dov lossis dov. Seamless pipes ua los ntawm cov roj av qis xws li 10 thiab 20 feem ntau yog siv rau cov raj xa dej.

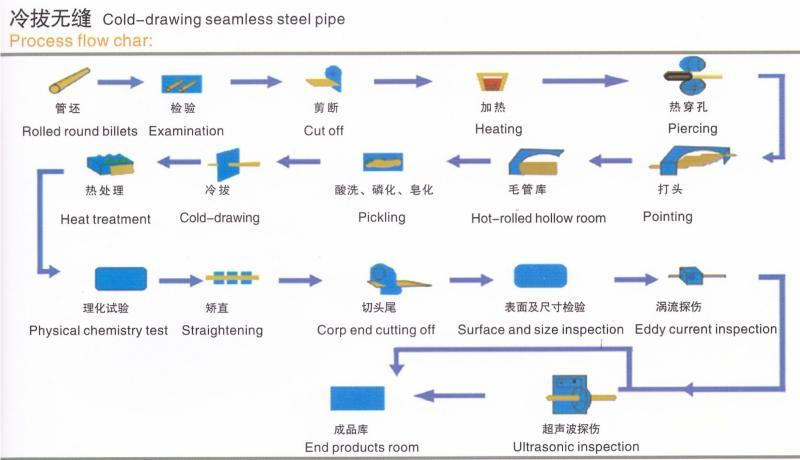

Feem ntau, cov txheej txheem ntau lawm ntawm Seamless Steel kav yog muab faib ua ob hom: cov txheej txheem kos duab txias thiab cov txheej txheem kub kub. Cov hauv qab no yog cov txheej txheem cej luam ntawm cov txheej txheem ntws ntawm txias-kos seamless steel kav thiab kub yaj seamless steel kav:

Khaub thuas-kos (txias-dov) seamless steel txheej txheem → kev tshuaj xyuas cua sov (kev ua kom sov thiab tshuaj lom neeg

Txias-dov seamless steel yeeb nkab yuav tsum yog ua ntej yuav tsum tau ua ntej rau peb-yob txuas ntxiv dov, thiab cov kev sim sizing yuav tsum tau ua tom qab extrusion. Yog tias tsis muaj lus teb tawg rau saum npoo, lub raj hloov lub raj yuav tsum tau txiav los ntawm txiav cov tshuab txiav thiab txiav mus rau hauv cov tsiaj nrog ntev txog ib meter. Tom qab ntawd sau cov txheej txheem anealing. Annaling yuav tsum yog pickling nrog kua acidic. Thaum lub sij hawm pickling, them sai sai rau seb nws muaj tus nqi loj ntawm cov npoo av nyob saum npoo. Yog tias muaj ntau npaum li cas ntawm npuas, nws txhais tau tias qhov zoo ntawm cov yeeb nkab steel tsis tau raws li cov qauv txheem sib xws.

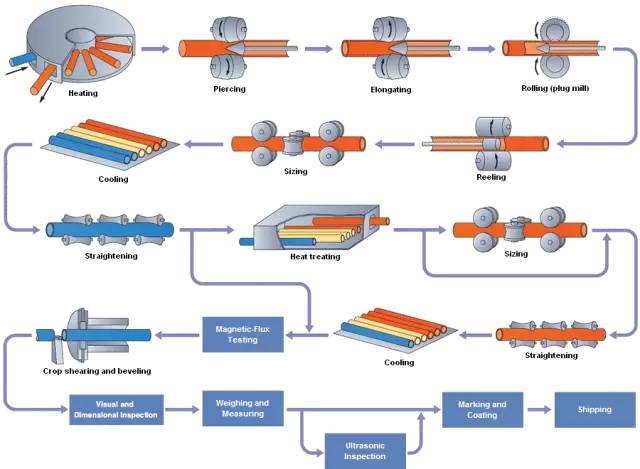

Kub-Rug (extruded) seamless steel yeeb nkab txheem ultrasonic → Rollation Rolling →

Kub Rolling, raws li lub npe implies, muaj qhov kub tshaj plaws rau cov dov daim, yog li deformation tiv taus yog me me thiab ib qho kev tiv thaiv loj heev tuaj yeem ua tiav. Tus me nyuam lub xeev kub-dov seamless steel kav yog feem ntau kub-dov thiab tshav kub kho ua ntej xa khoom. Cov raj raj yog kuaj thiab nto tsis xws luag, txiav mus rau qhov ntev ntawm lub raj, thiab tom qab ntawd xa mus rau cua sov thiab perforated rau ntawm cov perforator. Thaum perforating, nws rotates thiab txav mus rau pem hauv ntej. Raws li kev txiav txim ntawm cov yob thiab lub taub hau, cov kab noj hniav zuj zus hauv lub raj, uas yog hu ua raj. Tom qab lub raj raug tshem tawm, nws tau xa mus rau lub tshuab ua haujlwm xaim xaim rau ntau dua, thiab tom qab ntawd lub cheeb tsam txiav tau txiav txim siab los ntawm cov tshuab sizing kom tau raws li cov kev cai tshwj xeeb. Tom qab kev kho kub kub kub, kev sim ua kom zoo nkauj rau yuav tsum tau ua kom tiav. Yog hais tias lub taub dej perfaration loj dhau, nws yuav tsum ncaj thiab kho, thiab thaum kawg sau npe thiab muab tso rau hauv kev cia.

Kev sib piv ntawm cov txheej txheem kos duab txias thiab cov txheej txheem dov hluav taws xob: cov txheej txheem txias, tab sis sab nraud, thiab cov khoom tuab tuaj yeem ua tau nyias.

Qhov loj me: txoj kab uas hla sab nraud ntawm cov yeeb nkab uas tsis muaj zog yog ntau tshaj 32mm, thiab cov phab ntsa tuab yog 2.5-200 hli. Cov yeeb nkab sab nraud ntawm cov yeeb nkab uas txias tau tuaj yeem mus txog li 5 hli, thiab cov ntawv tuab ntawm phab ntsa uas tuaj yeem yog nce 0.25mm), thiab cov ntawv tuab ntawm phab ntsa uas muaj peev xwm nce ntxiv ntawm 0.2mm, thiab qhov tseeb ntawm phab ntsa ntawm cov rolling txias yog siab dua li ntawm kub dov.

Tsos: Txawm hais tias lub phab ntsa tuab ntawm cov yeeb nkab uas txias-dov

Cov xwm txheej xa khoom: Kub-Rolled steel kav yog xa hauv kub-rolled lossis kub-kho lub xeev, thiab txias-dov hlau kav hlau tau xa hauv lub xeev kub-kho.

Lub Sijhawm Post: Lub Yim Hli-21-2024