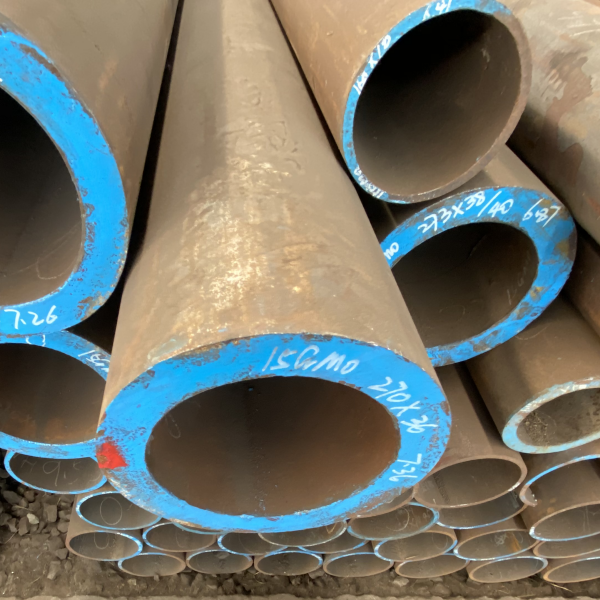

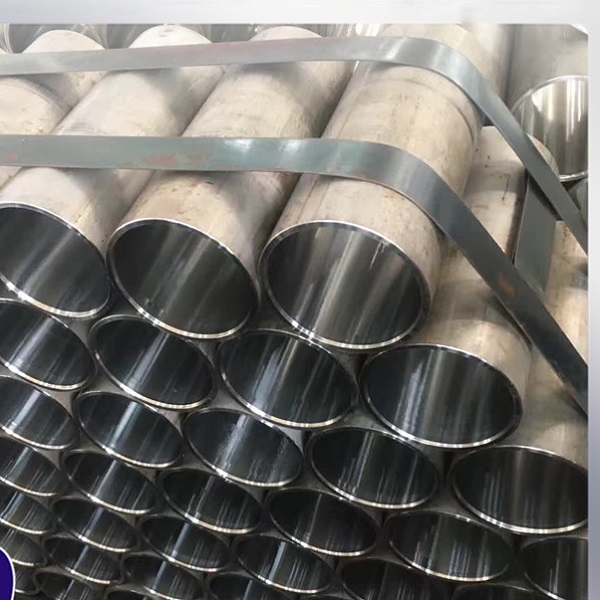

Seamless cov hlau tub rau roj av tawg, GB9948-2006, Sanon Yeeb Nkab

| Txheem:GB9948-2006 | Kev Kho Cua Sov: Annealing / Li Qub / Tempering |

| Pawg pab pawg: 10,12crmo, 15crmo, 07crrl9nil0, thiab lwm yam | Cov Inch txheej (Round): 10 - 1000 mm |

| Thickness: 1 - 100 hli | Daim Ntawv Thov: Kev Sib Pauv Cua Kub |

| Cov Inch txheej (Round): 10 - 1000 mm | Nto Kho: raws li cov neeg yuav tsum tau ua |

| Ntev: taag ntev lossis random ntev | Cov txheej txheem: Kub Rolled |

| Ntu puab: Round | Tshwj Xeeb Yeeb: Cov yeeb nkab tuab phab ntsa |

| Qhov chaw ntawm keeb kwm: Suav | Kev Siv: Kev Sib Txauv Tshav Kub |

| Ntawv pov thawj: ISO9001: 2008 | TEST: UT / MT |

Seamless cov hlau txiav rau cov roj av tawg yog siv rau cov yas seamless ntawm cov raj rau cub ua hluav taws xob, cov raj luj taws kub hauv kev lag luam petrochemical.

Cov khoom lag luam zoo carbon txheej qauv hlau yog 20G, 20mng thiab 25mng.

Allolo qauv qauv hlau: 15mog, 20mog, 12crmog

15crmog, 12cr2mog, 12crmovg, thiab lwm yam

Cov qib ntawm cov txiaj ntsig zoo carbon cov qauv hlau: 10 #,20 #

Zoo Siab Carbon Txheej Txheem Cov Qauv Hlau: 20G, 20mng thiab 25MNG

Allolo qauv qauv hlau: 15mog, 20mog, 12crmog, 12crmog, 12cr2mog, thiab lwm yam

| No | Teem nqi | Kev Siv Tshuaj Tiv Thaiv% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Zoo Carbon Qauv Qauv Hlau | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Alloy Qauv Hlau | 12Cro | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15crmo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Crlmo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12Crlmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12CR2MO | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12cr5moi | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12cr5mont | |||||||||||||

| 12cr9moi | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12CR9Mont | |||||||||||||

| Stainless cua sov resistant steel | 07crrl9nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07crr8nillb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07crl9nillti | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022crl7nil2mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

| Tsis muaj | Lub tensile MPa | Pub MPa | Elong tom qab sawb a /% | Lub Zog Hluav Taws Xob Hluav Taws Xob Kv2 / J | Brinell hardness naj npawb | ||

| duab | tus pas hlau | duab | tus pas hlau | ||||

| tsis tsawg tshaj li | tsis muaj ntau tshaj | ||||||

| 10 | 335~475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 4107550 | 245 | 24 | 22 | 40 | 27 | |

| 12Cro | 4107560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15crmo | 440000640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12Crlmo | 415 30560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Crlmov | 470~640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12CR2MO | 450 ~ 600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12cr5moi | 415~590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12cr5mont | 480~640 | 280 | 20 | 18 | 40 | 27 | - |

| 12cr9moi | 460~640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12CR9Mont | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7crl9nilo | 2520 | 205 | 35 | 187 HBW | |||

| 07crr8nillb | > 520 | 205 | 35 | - | 187 HBW | ||

| 07crl9nillti | > 520 | 205 | 35 | - | - | 187 HBW | |

| 022crl7nil2mo2 | > 485 | 170 | 35 | 一 | - | 187 HBW | |

| Rau cov hlau nrog phab ntsa tuab tsawg dua 5 hli raj tsis ua rau kev sim hardness | |||||||

Kev Kuaj Hydraulic

Kev ntsuas kev ntsuas hydraulic yuav tsum tau nqa tawm rau cov kav hlau hlau ib qho los ntawm ib qho. Qhov ntsuas qhov siab tshaj plaws yog 20 MPA. Nyob rau hauv qhov kev ntsuas siab, lub sijhawm ua haujlwm ruaj khov yuav tsum tsis pub tsawg tshaj 10 s, thiab to steel yeeb nkab tsis pub.

Plhaw kev kuaj

Flattening kev kuaj mob yuav tsum tau ua rau cov yeeb nkab steel nrog rau txheej hla ntau dua 22 hli

Flaring Test

Zoo siab carbon txheej txheem hlau thiab stainless-resistant) steel kav ntawm tsis ntau tshaj li 76 mm thiab ib phab ntsa tuab ntawm tsis ntau tshaj 8 hli yuav raug nthuav dav. Txoj kev npau taws yuav tsum nqa tawm ntawm chav tsev kub. Lub Inch sab nraud Flaring tus nqi ntawm cov qauv tom qab taper Core Taper yog 60% ntawm cov kab nrib pleb Raws li cov kev xav tau ntawm cov neeg xav tau thiab sau tseg hauv daim ntawv cog lus, cov hlau alloy txheej txheem kuj tseem tuaj yeem siv rau kev ntsuas.

Nondestructive Teste

Tus kav hlau hlau yuav tsum raug ultrasonic qhov khuam nrhiav kom muaj ib qho los ntawm ib qho nyob rau hauv raws li cov kev cai ntawm GB / T 5777-2008. Raws li cov cai yuav tsum tau ua ntawm cov neeg xav tau, lwm yam kev ua txhaum cai tsis ua txhaum cai ntxiv tom qab kev sib ceg ntawm cov khoom xa khoom thiab cov xav tau thiab qhia hauv daim ntawv cog lus.

Sib Tw Sib Tham Corrosion

Kev xeem corrosion yuav tsum tau ua rau stainless (kub-resistant) steel yeeb nkab. Txoj kev xeem yuav tsum ua raws li cov kev cai ntawm Suav cov qauv e hauv GB / T 4334-2008, thiab intergranular corrosion nyiam tsis pub tom qab kuaj.

Tom qab kev sib raug zoo ntawm cov chaw muag khoom thiab cov neeg xa khoom, thiab sau tseg hauv daim ntawv cog lus, qhov xav tau tuaj yeem xaiv lwm cov kev xeem corrosion.

Roj, petrochemical, kev kub siab boil, kev siv tshwj xeeb ntawm seamless lub raj, geological seamless steel raj thiab roj seamless raj.

Cov Khoom Siv Siv Tshuaj

| hom | Kev tivthaiv feem (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| 15crmo | 0.12 ~ 0.18 | 0.40 ~ 0.70 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | I≤0.30 | _ | I≤0.035 | I≤0.035 |

Cov Cuab Yeej Cuab Yeej Cuab Yeej

| hom | Lub tensile MPa | Pub MPa | Elongation (%) |

| 15crmo | 440 ~ 640 | 295 | 22 |