Ihe na-enweghị atụ, a na-eji ọla nchara nchara ma ọ bụ bọọ tube dị mma site na perforation n'ime tube siri ike, wee na-ekpo ọkụ ma ọ bụ oyi. A na-ejikarị ihe a na-eme dị ka 10,20, 30, 35,45, ala alloy nkpu dikaIri na isii, 5mnv ma ọ bụ steel steel dị ka 40cr, 30cmnsi, 45mn2, 40mn site na mpịakọta na-ekpo ọkụ ma ọ bụ mpịakọta oyi. A na-eji eriri na-enweghị isi nke carbon steel dị ka 10 na 20 na-ejikarị maka pipelines ikuku.

A na-eke ihe nkwapụta nke nchara nchara nchara na ụdị abụọ: usoro ịse na usoro ịwụ ọkụ. Ihe ndị a bụ nyocha nke usoro na-erute mmiri nke na-enweghị atụ na-adọkpụ nke na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie.

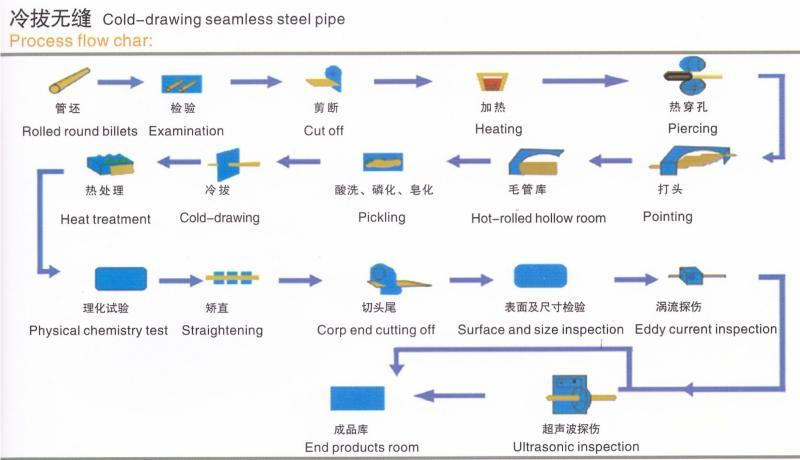

Mpempe akwụkwọ na-enweghị atụ (nke na-atụ mmiri) na-eme nkwadebe na usoro nkwadebe → FEZE TELTE na-emegharị → tube, na-enweghị ike, anụ ahụ, bench) → Nchekwa

A ga-ebu ụzọ sọlfọ na-enweghị atụ na-aga n'ihu na-aga n'ihu na-aga n'ihu na-aga n'ihu na-aga n'ihu na-aga n'ihu. Ọ bụrụ na enweghị nzaghachi nzaghachi dị n'elu, ọ ga-ebipụ gburugburu tube ga-egbutu ya ma bee n'ime ijeri na ogologo nke otu mita. Wee tinye usoro na-enye obi. A ga-eji mmiri acctic acceaming. N'oge ị na-ehicha, toaa ntị na ọ bụ nnukwu eguzo n'elu. Ọ bụrụ na enwere nnukwu ego, ọ pụtara na ịdị mma nke ọkpọkọ nchara anaghị ezute ụkpụrụ ndị kwekọrọ.

Mpempe akwụkwọ na-ekpo ọkụ (exuded) usoro nchara na-enweghị atụ: routing → fatịlaịza → Confting → bọmbụ na-aga n'ihu → bọmbụ mgbatị ahụ) → Marking →

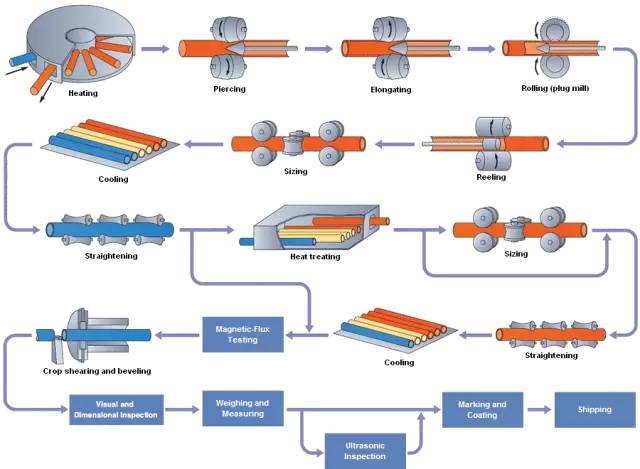

Ntughari na-ekpo ọkụ, dị ka aha ahụ pụtara, nwere ọnọdụ okpomọkụ dị elu maka mpempe akwụkwọ a na-akpọ ya, yabụ enwere ike ibute obere nrụrụ. Ọnọdụ nnyefe nke igwe na-acha uhie uhie na-acha uhie uhie na-ekpo ọkụ na-ekpo ọkụ na okpomọkụ - ọgwụgwọ tupu nnyefe. A na-enyocha tube siri ike ma na-ebelata ogologo achọrọ, hiwere na njedebe nke njedebe na-emebi emebi maka ikpo ọkụ ma sie ike na onye na-eme mkpọtụ. Ọ bụ ezie na ndị na-efe efe, ọ na-agbagharị ma na-aga n'ihu n'ihu. N'okpuru ime ihe nke rollers na isi, nke ji nwayọọ nwayọọ na-eji nwayọọ nwayọọ na ọkpọ, nke a na-akpọ tube siri ike. Mgbe ewepụ tube ahụ, a na-eziga ya na akpakasị igwe na-ebugharị ngwa ngwa, mgbe ahụ ọkpụrụkpụ mgbidi na-agbanwe site na igwe na-emegharị ahụ, ma dayameta na-ekpebikwa ihe ịhazi chọrọ. Mgbe ọgwụgwọ ọkụ na-enwu ọkụ, a ga-eme nnwale perforation. Ọ bụrụ na dayameta na-aba ụba buru oke ibu, a ga-agbatị ma rụọ ya ma mezie ya, ma tinye ya ma tinye ya na nchekwa.

Tụnyere usoro ịse na usoro ịwụpụta na-ekpo ọkụ: Usoro mpịakọta oyi na-agbagha, ma elu, ọdịdị dị mma karịa nke efere na-ekpo ọkụ, ma ọkpụrụkpụ ngwaahịa nwere ike ịbụ gị dị gịrịgị.

Ogo: Mpempe akwụkwọ nke na-acha uhie uhie na-ekpo ọkụ karịa 32mm, na mgbidi ọkpụrụkpụ bụ 2.5-200mm. Mpempe akwụkwọ nke na-apụ apụ apụ nwere ike ịdị ruo afọ iri isii na ise, ọkpụrụkpụ mgbidi nwere ike ịdị 0.25mm (ọkpụrụkpụ mgbidi ahụ na-erughị 0.2mm), na akụkụ nke ịtụgharị na-ekpo ọkụ dị elu karịa nke ịtụgharị na-ekpo ọkụ.

Ọdịdị: Ọ bụ ezie na mgbidi ahụ na-enweghị atụ na-enweghị isi karịa nke na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie na-acha uhie uhie, elu ahụ adịghịkwa ọtụtụ ndị na-efe efe.

Ọnọdụ nnyefe: a na-enyefe ọkwa nnyefe: A na-enyefe ya ọkpọkọ nchara na-acha uhie uhie ma ọ bụ nke na-agwọ ọrịa, na-enyefe ya ọkpọ oyi na ọnọdụ ọkụ.

Oge Post: August-21-2024