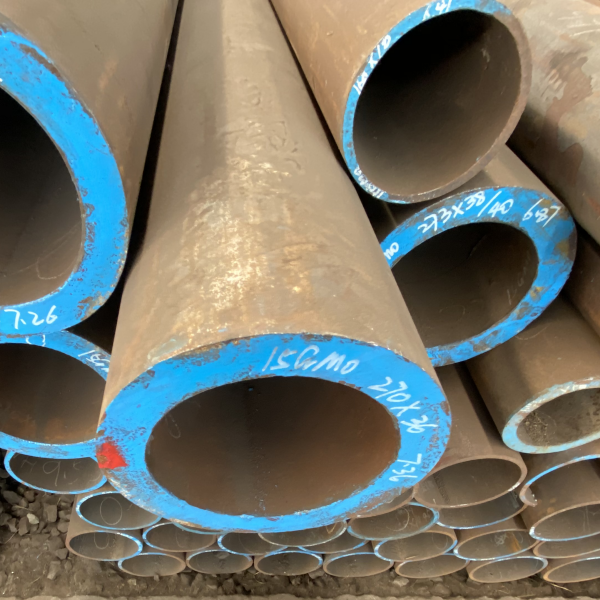

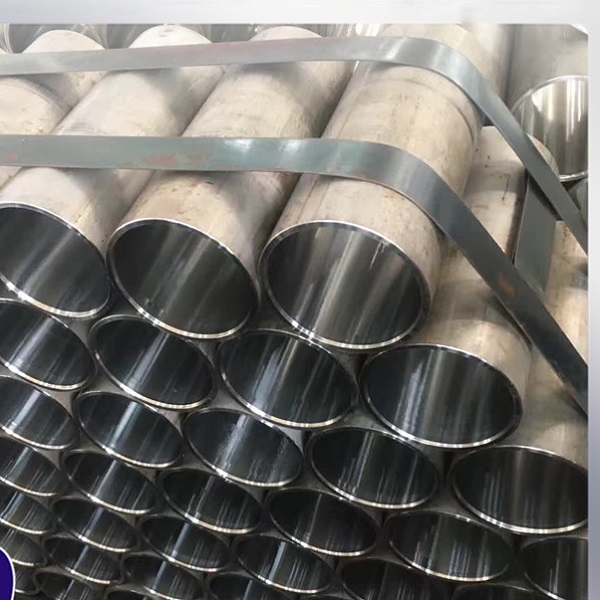

Akpa uwe na-enweghị nchara maka mmanụ ụgbọ mmiri, gb9948-2006, Santon pipe

| Standard:Gb9948-2006 | Ọgwụgwọ ọkụ: na-egbu egbu / na-arụ ọrụ / iwe |

| Otu klas: 10,12crmo, 15crmo, 07crl9nil0, wdg | Mpụga dị omimi (gburugburu): 10 - 1000 mm |

| Ọkpụrụkpụ: 1 - 100 mm | Ngwa: Enweghi ike |

| Mpụga dị omimi (gburugburu): 10 - 1000 mm | Ọgwụ elu: dị ka ihe ndị ahịa chọrọ |

| Ogologo: ogologo ogologo ma ọ bụ ogologo ogologo | Usoro: na-ekpo ọkụ |

| Akụkụ akụkụ: Ọkpụkpụ | Akpọkọta Pụrụ Iche: Ọkpọkọ mgbidi |

| Ebe Si Malite: China | Ojiji: Okpomoku |

| Asambodo: ISO9001: 2008 | Nnwale: UT / MT |

Akpa uwe na-enweghị atụ maka crackim crucking na-emetụta akpa na-enweghị atụ maka akpa na-enweghị atụ, mgbanwe na-agbanwe na ụlọ ọrụ petrochemical.

Mpempe akwụkwọ nke carbon dị elu bụ 20g, 20mng na 25mng.

Akara uloy nchara: 15mog, 20mog, 12CROG

15CROG, 12CR2MOG, 12crmovg, wdg

Ngalaba carbon dị elu nke carbon dị elu: 10 #,20 #

Usoro akara aka carbon dị elu: 20G, 20mng na 25mng

Akara uloy usoro: 15mog, 20mog, 12CROG, 15CROG, 12CR2Mog, wdg

| No | Greedi | Ngwakọta kemịkalụ% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| A na-arụ ọrụ carbon dị elu | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - - | - - | <0. 08 | <0. Keigwu | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - - | - - | <0. 08 | <0. Keigwu | 0. 025 | 0. 015 | |

| Nchara alloy nzọ | 12crmo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 7.0 | 0. 40-0. 7.0 | 0. 40 -0.55 | <0. Iri ato | - - | - - | 一 | <0. Keigwu | 0. 025 | 0. 015 |

| Mpostmo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 7.0 | 0. 80-1.1 | 0. 40-0.55 | <0. Iri ato | - - | - - | 一 | <0. Keigwu | 0. 025 | 0. 015 | |

| 12clmo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. Eri iri ise | 0.45 -0.65 | <0. Iri ato | - - | - - | - - | <0, 20 | 0. 025 | 0. 015 | |

| 12clmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 7.0 | 0.90-1.2 | 0. 25 -0.35 | <0. Iri ato | - - | - - | 0.15 -0. Iri ato | <0. Keigwu | 0.025 | 0. 010 | |

| 12cr2mo | 0.08-0.15 | <0. Eri iri ise | 0. 40-0. 60 | 2. 00-2. Eri iri ise | 0. 90-1.13 | <0. Iri ato | - - | - - | 一 | <0. Keigwu | 0. 025 | 0. 015 | |

| 12cr5moi | <0.15 | <0. Eri iri ise | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - - | - - | <0. Keigwu | 0. 025 | 0. 015 | ||

| 12cr5mont | |||||||||||||

| 12cr9moi | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - - | - - | - - | <0. Keigwu | 0. 025 | 0, 015 | |

| 12cr9mont | |||||||||||||

| Igwe na-acha uhie uhie na-eguzogide | 07clt9nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - - | 8. 00-11 | - - | - - | - - | - - | 0. 030 | 0. 015 |

| 07crl8nillnb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - - | 9.00-12. 00 | 8c-1.1 | - - | - - | - - | 0. 030 | 0. 015 | |

| 07crl9nillti | 0. 04-0.1 | <0. 7.5 | <2. 00 | 17.00-20. 00 | - - | 9. 00 ~ 13. 00 | - - | 4c-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022cll7nil2mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - - | 一 | 一 | - - | 0.03 | 0. 015 | |

| Mba | Tensile Anamba | Mmụba Anamba | Elong mgbe ọ gachara /% | Shork na-eri nri kv2 / J | Brinell siri ike | ||

| onu uzo | transfe | onu uzo | transfe | ||||

| obughi ihe na-erughị | ọ dịghị karịa | ||||||

| 10 | 335Y475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410~550 | 245 | 24 | 22 | 40 | 27 | |

| 12crmo | 410~560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| Mpostmo | 440~640 | 295 | 21 | 19 | 40 | 27 | 170 hbw |

| 12clmo | 415~560 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12clmov | 470~640 | 255 | 21 | 19 | 40 | 27 | 179 hbw |

| 12cr2mo | 450 ~ 600 | 280 | 22 | 20 | 40 | 27 | 163 hbw |

| 12cr5moi | 415~590 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12cr5mont | 480~640 | 280 | 20 | 18 | 40 | 27 | - - |

| 12cr9moi | 460~640 | 210 | 20 | 18 | 40 | 27 | 179 hbw |

| 12cr9mont | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7cll9nilo | 2520 | 205 | 35 | 187 hbw | |||

| 07crl8nillnb | > 520 | 205 | 35 | - - | 187 hbw | ||

| 07crl9nillti | > 520 | 205 | 35 | - - | - - | 187 hbw | |

| 022cll7nil2mo2 | > 485 | 170 | 35 | 一 | - - | 187 hbw | |

| Maka ígwè na mgbidi ọkpụrụkpụ ihe na-erughị 5mm tube anaghị eme ka ọ bụrụ nnwale siri ike | |||||||

Nlele Hydraulic

A ga-eme nyocha hydraulic maka nchara pinye otu n'otu. Nnwale nnwale kachasị bụ 1 MPA. N'okpuru nrụgide ule, oge mgbagide agaghị adị ihe na-erughị 10 s, na ngwakọta nke nchara pipe.

Ule na-eme

A ga-eduzi ule na-acha uhie uhie maka ọkpọ ọkpọ dị ukwuu karịa 22 mm

Ule na-enwu enwu

Akwa carbon dị elu nke carbon dị elu (igwe na-eguzogide) ọ bụghị ihe karịrị 76 mm na mgbidi ọkpụrụkpụ nke enweghị ihe karịrị 8 mm ga-edobe ule. A ga-eme nnwale ahụ ọkụ na ụlọ okpomọkụ. Oghere dị iche iche na-enwu enwu nke ihe atụ ahụ mgbe elu isi taper bụ 60% nke ọkụ ga-ezute ihe ndị a chọrọ na ntuli aka ahụ mgbe ọkụ gachara. Dabere na ihe ndị achọrọ nke onye na-achọ ahụ ma kwuo na nkwekọrịta ahụ, enwere ike iji alloy owuwe ihe eji eme ihe maka ule.

Na-elele nnwale

Ọkpọkọ nchara ga-abụ na-eleba anya na nchọpụta Nchọpụta Ultrasonic otu otu n'otu dabere na ndokwa nke GB / T 5777-2008. Dabere na ihe ndị chọrọ chọrọ, enwere ike ịgbakwunye ule ndị ọzọ na-enweghị ike mgbe mkparịta ụka dị n'etiti ndị na-eweta ya na ndị na-achọ ọrụ na-egosi na nkwekọrịta ahụ.

Nnwale Corrisonion

A ga-eduzi ule intersosion maka ikpo nchara (okpomoku). Usoro nnwale ahụ ga-adị na usoro nke usoro ndị China e na GB / T 4334-2008, anaghị anabata ụdị mmekọrịta corrisonion mgbe ule ahụ gasịrị.

Mgbe mkparịta ụka dị n'etiti onye na-eweta ya na onye na-achọ ihe, ma gosipụta na nkwekọrịta ahụ, onye na-achọ ihe nwere ike ịkọwa usoro ule ule ndị ọzọ.

Mmanụ, Putrochemical, nnukwu nrụgide nke tuber na-enweghị atụ nke eriri na-enweghị isi, Geological Semically nchara tube na mmanụ enweghị isi.

Mkọrọ kemịkal

| udi anumanu | Akụrụngwa kemịkal (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| Mpostmo | 0.12 ~ 0.18 | 0.40 ~ 0.70 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Ngwongwo nke mebere

| udi anumanu | Tensile Anamba | Mmụba Anamba | Elongation (%) |

| Mpostmo | 440 ~ 640 | 295 | 22 |