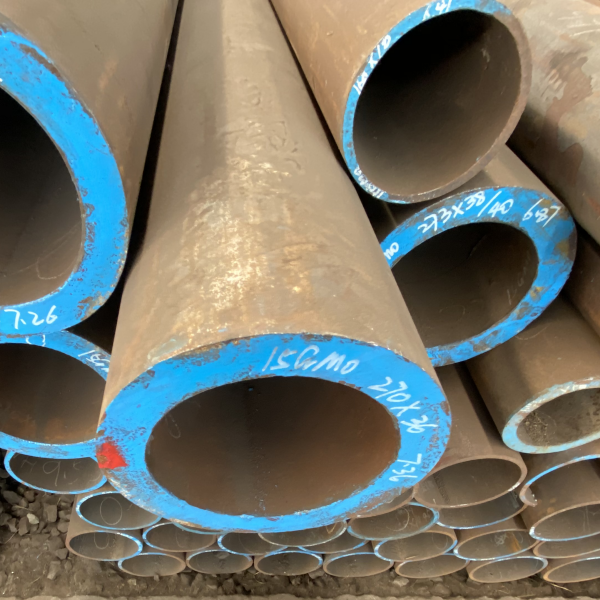

Tabung baja kanthi lancar kanggo cracking minyak, GB9948-2006, Pipa Sanon

| Standard:GB9948-2006 | Perawatan Panas: Annealing / Negiis / Normal |

| Kelompok Kelas: 10,12crmo, 15crmo, 07crl9nil0, lsp | Diameter njaba (babak): 10 - 1000 mm |

| Kekandelan: 1 - 100 mm | Aplikasi: tabung ijol-ijolan panas |

| Diameter njaba (babak): 10 - 1000 mm | Perawatan permukaan: Minangka syarat pelanggan |

| Length: Dawane tetep utawa dawa acak | Teknik: panas digulung |

| Bentuk bagean: Babak | Pipa Khusus: pipa tembok kenthel |

| Papan Asal: China | Dianggo: Tabung ijol-ijolan panas |

| Sertifikasi: ISO9001: 2008 | Tes: UT / MT |

Tabung baja lancarum kanggo cracking petrole ditrapake kanggo tabung baja lancar kanggo tabung baja lancar kanggo tabung tungku, tabung panas lan pipa tekanan ing industri petrochemical.

Gerbang baja karbon karbon berkualitas tinggi yaiku 20g, 20mng lan 25mng.

Gelang baja struktural: 15mog, 20mog, 12Crmog

15Crmog, 12Cr2mog, 12Crmovg, lsp

Baja Struktural Karbon Berkualitas Berkualitas: 10 #,20 #

Gerbang baja karbon karbon berkualitas tinggi: 20g, 20mng lan 25mng

Gerbang baja strukture: 15mog, 20mog, 12Crmog, 15Crmog, 12Cr2mog, lsp

| No | Kelas | Komponen Kimia% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Baja Struktural Karbon Berkualitas tinggi | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0.15 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0.15 | |

| Baja strukture wesi | 12Cro | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0.15 |

| 15crmo | 0.12 -0.18 | 0.17-0. 37 | 0,40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0.15 | |

| 12Crmo | 0. 08 -0.15 | 0,50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0.15 | |

| 12Crmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1,2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0,025 | 0. 010 | |

| 12Cr2mo | 0,08-0.15 | <0. 50 | 0. 40-0. 60 | 2 .. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0.15 | |

| 12Cr5moi | <0.15 | <0. 50 | 0,30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0.15 | ||

| 12CrinT | |||||||||||||

| 12Cr9moi | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9mont | |||||||||||||

| Baja tahan panas tahan | 07Crl9nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0.15 |

| 07Crl8nillnb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8c-1.1 | - | - | - | 0. 030 | 0.15 | |

| 07Crl9nillti | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4c-0. 60 | 一 | 一 | 0,03 | 0.15 | |

| 022CRL7nil2mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2 .. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0,03 | 0.15 | |

| Ora | Tensile MPA | Ngasilake MPA | Elong sawise patah a /% | Penyerapan Shork Energy KV2 / J | Nomer Hardness Brinell | ||

| Potret | transver | Potret | transver | ||||

| ora kurang saka | ora luwih saka | ||||||

| 10 | 335~475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410~550 | 245 | 24 | 22 | 40 | 27 | |

| 12Cro | 410~560 | 205 | 21 | 19 | 40 | 27 | 156 hbw |

| 15crmo | 440~640 | 295 | 21 | 19 | 40 | 27 | 170 hbw |

| 12Crmo | 415~560 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12Crmov | 470~640 | 255 | 21 | 19 | 40 | 27 | 179 hbw |

| 12Cr2mo | 450 ~ 600 | 280 | 22 | 20 | 40 | 27 | 163 hbw |

| 12Cr5moi | 415~590 | 205 | 22 | 20 | 40 | 27 | 163 hbw |

| 12CrinT | 480~640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9moi | 460~640 | 210 | 20 | 18 | 40 | 27 | 179 hbw |

| 12Cr9mont | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9nilo | 2520 | 205 | 35 | 187 hbw | |||

| 07Crl8nillnb | > 520 | 205 | 35 | - | 187 hbw | ||

| 07Crl9nillti | > 520 | 205 | 35 | - | - | 187 hbw | |

| 022CRL7nil2mo2 | > 485 | 170 | 35 | 一 | - | 187 hbw | |

| Kanggo baja nganggo kekandelan tembok kurang saka tabung 5mm ora nggawe eksperimen atos | |||||||

Tes hidraulik

Tes hidraulik bakal ditindakake kanggo pipa baja siji-siji. Tekanan tes maksimal yaiku 20 MPA. Ing tekanan tes, wektu stabilisasi ora kurang saka 10 s, lan bocor pipa baja ora diidini.

Tes flattening

Tes flattening bakal ditindakake kanggo pipa baja kanthi diameter njaba luwih saka 22 mm

Tes FLING

Pipo baja struktural karbon kanthi kualitas tinggi lan pipa stainless (panas-tahan) kanthi diameter njaba ora luwih saka 76 mm lan kekandelan tembok ora luwih saka 8 mm bakal kena ukurane. Tes flaring bakal ditindakake ing suhu kamar. Tingkat pethi diameteripun njaba sampel kasebut sawise taper inti ndhuwur yaiku 60% flaring bakal memenuhi syarat Tabel 7. Ora ana retak utawa retakan diidini. Miturut syarat-syarat demander lan nyathet ing kontrak kasebut, baja wesi struktural uga bisa digunakake kanggo tes sing berkembang.

Teste nondestruktif

Pipa baja kudu tundhuk deteksi cacat ultrasonik siji-siji miturut syarat GB / T 5777-2008. Miturut syarat-syarat demander, tes sing ora ngrusak liyane bisa ditambahake sawise negosiasi antarane supplier lan demander lan dituduhake ing kontrak kasebut.

Tes karat interganular

Tes karat intergrain kudu ditindakake kanggo pipa baja stainless (panas-tahan). Cara tes bakal sesuai karo ketentuan Metode Cina E ing GB / T 4334-2008, lan korosi karat intergranular ora diidini sawise tes kasebut.

Sawise negosiasi antarane supplier lan demander, lan nyathet ing kontrak kasebut, demander bisa nunjukake cara tes karat liyane.

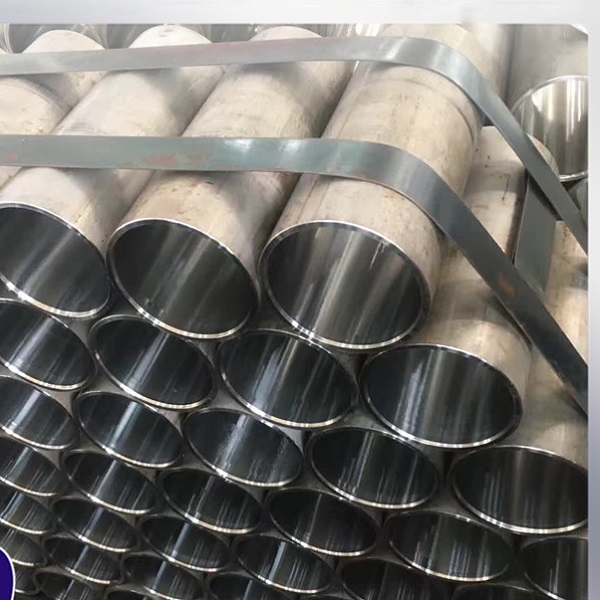

Minyak, petrokimia, dandang tekanan tinggi, panggunaan khusus boiling lancar tabung lancar, tabung baja seamless Geologel lan tabung minyak lancar.

Komponen Kimia

| merek | Komponen Kimia (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| 15crmo | 0.12 ~ 0.18 | 0,40 ~ 0.70 | 0.17 ~ 0.37 | 0,80 ~ 1.10 | 0,40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Properti Mekanikal

| merek | Tensile MPA | Ngasilake MPA | Elongasi (%) |

| 15crmo | 440 ~ 640 | 295 | 22 |