Calidum complevit structural inanis sectiones non-stillam et denique frumentum steels

| Latin: Bsen10210-1-2006 | Alloy et non: Non |

| Gradus Group: S235GRH, S275JOH, S275J2H, S355JO, S355J2H | Applicationem: structuram |

| Crassitudo: I - C mm | Superficies curatio, ut mos est scriptor postulationem |

| Exterius diameter (per) X - M mm | Technique: Hot advolvit vel frigus advolvit |

| Longitudo, fixa longitudine longitudo temere | Calor curatio: annealing / normalizing / accentus reliing |

| Sectioni figura, circum | Special Pipe: Pipe |

| Locus Origin: Sina | Usus: mechanica structuram, generalis structuram |

| Certification: ISO9001: MMVIII | Test: ET / UT |

Est maxime propter mechanica structuram, generalis structuram.

S235grh, S275JO, S275J2H, S355JOH, S355J2H

| gradus | Deeoxygenated Typus est | % Missam, maximum | |||||||

| Nomen ferro | CHRISTERIUM | C Praescribitur murum crassitudine mm | Si | Mn | P | S | NBC | ||

| ≤ XL | > 40≤ CXX | ||||||||

| S235jrh | 1.0039 | FN | 0.17 | 0,20 | - | 1.40 | 0.040 | 0.040 | 0.009 |

| S275j0h | 1.0149 | FN | 0,20 | 0,22 | - | 1.50 | 0.035 | 0.035 | 0.009 |

| S275j2h | 1.0138 | FF | 0,20 | 0,22 | - | 1.50 | 0.030 | 0.030 | - |

| S355j0h | 1.0547 | FN | 0,22 | 0,22 | 0,55 | 1.60 | 0.035 | 0.035 | 0.009 |

| S355j2h | 1.0576 | FF | 0,22 | 0,22 | 0,55 | 1.60 | 0.030 | 0.030 | - |

| S355k2h | 1.0512 | FF | 0,22 | 0,22 | 0,55 | 1.60 | 0.030 | 0.030 | - |

| A definitione Dei Poxidation modum est ut sequitur: FN = ferventis ferro non licet Ff = plene-occidit ferro continet nitrogen-binding elementa in moles sufficient ad alligandum potest NITROGENIUM (Eg 0.020% minimum totalis aluminium aut 0.015% solutum aluminium) B est liceat excedat certa valore, ut dum n Content crescit per 0.001%, maximum contentus de p minuitur 0.005% simul. In n contentus in Smelting analysis non excedunt 0.012%. C compositio ostendit a minimum totalis aluminium contentus 0.020% et minimum aluminium et aluminium aluminium / II Ratio II: I, aut si alias sufficient NITROGENIUM content fines non applicare. Nitrogen binding elementa notandum in inspectionem documentum congruit.

| |||||||||

| Gradus | Minimum Cede | tensile viribus | Minimum elongatio | Minimum impulsum potentia | |||||||||||||

| Nomen ferro | Numerus ferro | Vexillum crassitudine | Vexillum crassitudine | Vexillum crassitudine | Vexillum crassitudine | ||||||||||||

| ≤16 | XVI | > XL | > LXIII | > LXXX | > C | ≤3 | > III | > C | ≤40 | > 40≤63 | > 63≤100 | > 100≤120 | -20 ℃ | 0 ℃ | XX ℃ | ||

| ≤ XL | LXIII ≤ | ≤ LXXX | ≤ C | ≤ CXX | ≤100 | ≤ CXX | |||||||||||

| S235jrh | 1.0039 | CCXXXV | CCXXV | CCXV | CCXV | CCXV | CXCV | 360-510 | 360-510 | 360-500 | 26 | 25 | 24 | 22 | - | - | 27 |

| S275j0hc | 1.0149 | CCLXXV | CCLXV | CCLV | CCXLV | CCXXXV | CCXXV | 430-580 | 410-560 | 400-540 | 23 | 22 | 21 | 19 | - | 27 | - |

| S275j2h | 1.0138 | 27 | - | - | |||||||||||||

| S355j0hc | 1.0547 | CCCLV | CCCXLV | CCCLV | CCCXXV | CCCXV | CCXCV | 510-680 | 470-630 | 450-600 | 22 | 21 | 20 | 18 | - | 27 | - |

| S355j2h | 1.0576 | 27 | - | - | |||||||||||||

| S355k2h | 1.0512 | 40 | - | - | |||||||||||||

| A longitudinalis sample valorem. A vexillum valorem de transversum specimen est II% inferior quam hoc value.b ad crassitudines <3mm, videatur 9.2.2.c tantum cum optionem 1.3 applicantur, confirmatio est equivalent ad -30 ° C (videatur en 1993-1-1. | |||||||||||||||||

Durness test, tensio probat, nondestruccently probat, ferrum munditiam, hardenenability, flaring test

Supple facultatem: MM tons per mensis per gradus de Bsen10210-1-2006 ferro pipe

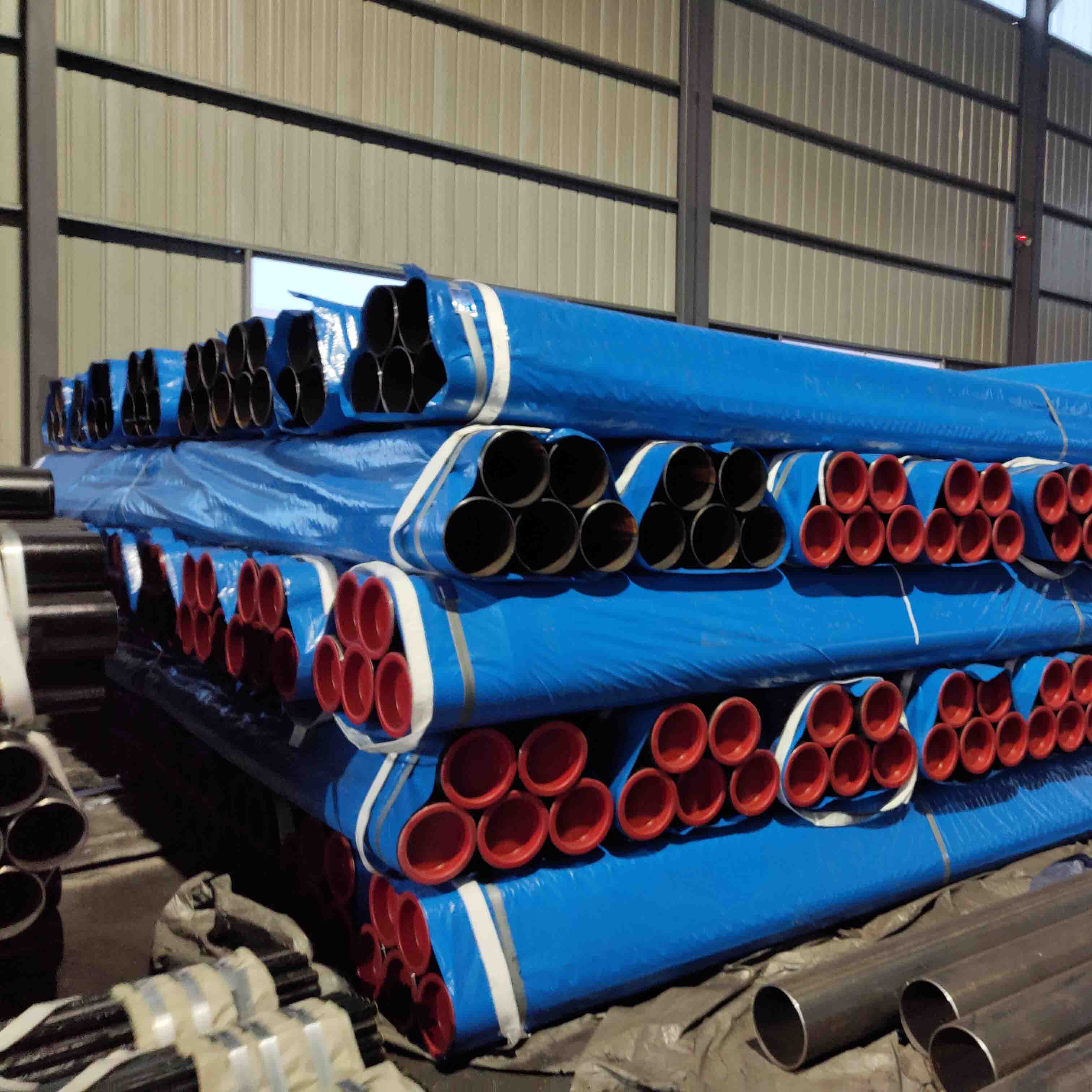

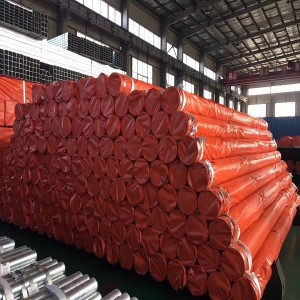

In bundles et fortes lignea arca

7-14 diebus, si in stirpe, 30-45 dies ad producendum

XXX% Desoit, LXX% L / C vel B / L Effingo vel C% L / C ad visus