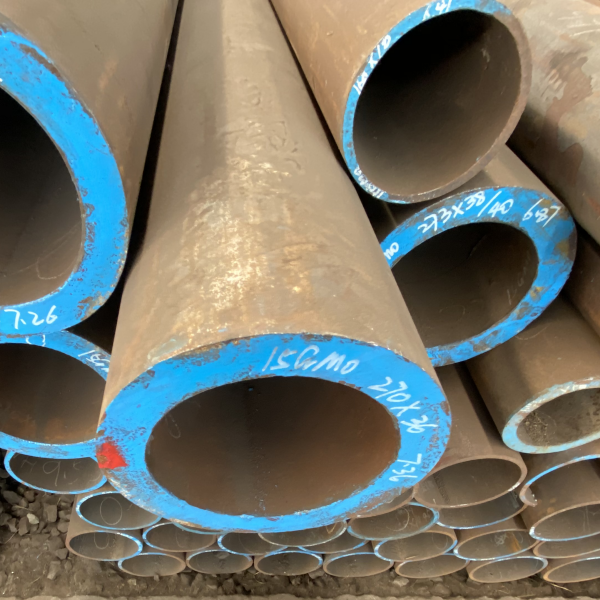

Seamless Steel tubulis PETROLEUM Cracking, GB9948-2006, Sanon Pipe

| Latin:GB9948-2006 | Calor curatio: Annealing / Normalizing / Tempering |

| Gradus Group: 10,12CRMM, 15Crmo, 07Crl9nil0, etc. | Exterius diameter (per) X - M mm |

| Crassitudo: I - C mm | Application: Heat Exchange Tubes |

| Exterius diameter (per) X - M mm | Superficies curatio, ut mos est scriptor postulationem |

| Longitudo, fixa longitudine longitudo temere | Technique: Hot advolvit |

| Sectioni figura, circum | Special Pipe: Pipe |

| Locus Origin: Sina | Usus: Heat Exchange Tubes |

| Certification: ISO9001: MMVIII | Test: UT / Mt |

Seamless Steel tubulis pro PETROLEUM Cracking sunt applicabilis ad seamless Steel tubulis fornacem tubulis, calor commutationem fistulae et pressura fistularum in petrochemical industria.

Quality Carbon Structural Steel Gradus 20g, 20mng et 25mng.

Alloy structural Steel grades: 15mog, 20mog, 12crmog

15crmog, 12cr2mog, 12crmovg, etc.

Gradus summus qualitas ipsum fabrica ferro: X #,XX #

High quality ipsum Structural Steel Grades: 20g, 20mng et 25mng

Structural Steel grades: 15mog, 20mog, 12crmog, 15crmog, 12cr2mog, etc.

| No | Gradus | Chemica pars% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| High quality ipsum fabrica ferro | 10 | 0. 07-.13 | 0,17 -0. XXXVII | -0.65 0,35 | <0.15 | <0.15 | <0. XXV | - | - | <0. VIII | <0. XX | 0. XXV | 0. XV |

| 20 | 0.17-0. XXIII | 0,17 -0. XXXVII | -0.65 0,35 | <0. XXV | <0.15 | <0. XXV | - | - | <0. VIII | <0. XX | 0. XXV | 0. XV | |

| Alloy structural ferro | 12Crmo | 0. 08-.15 | 0,17 -0.37 | 0. 40-0. LXX | 0. 40-0. LXX | 0. XL -0.55 | <0. XXX | - | - | 一 | <0. XX | 0. XXV | 0. XV |

| 15Crmo | 0,12 -0.18 | 0.17-0. XXXVII | 0,40 -0. LXX | 0. 80-1.1 | 0. 40-0.55 | <0. XXX | - | - | 一 | <0. XX | 0. XXV | 0. XV | |

| 12crlmo | 0. VIII -0.15 | -1.50 -1. 00 | 0. 30-0.6 | 1.00-1. L | -0.65 0.45 | <0. XXX | - | - | - | <0, XX | 0. XXV | 0. XV | |

| 12crlmov | 0. 08-.15 | 0.17-0. XXXVII | 0. 40-0. LXX | 0,90-1.2 | 0. XXV -0.35 | <0. XXX | - | - | 0.15 -0. XXX | <0. XX | 0.025 | 0. X | |

| 12cr2mo | 0.08-0..15 | <0. L | 0. 40-0. LX | II. 00-2. L | 0. 90-1.13 | <0. XXX | - | - | 一 | <0. XX | 0. XXV | 0. XV | |

| 12Cr5Moi | <0.15 | <0. L | 0.30-0.6 | IV. 00-6 | 0. XLV -0. LX | <0. LX | - | - | <0. XX | 0. XXV | 0. XV | ||

| 12Cr5mont | |||||||||||||

| 12Cr9Moi | <0.15 | 0. 25-1. 00 | 0. 30-0. LX | 8.00 -10. 00 | 0. 90-1.1 | <0. LX | - | - | - | <0. XX | 0. XXV | 0, XV | |

| 12cr9mont | |||||||||||||

| Aliquam calor repugnant ferro | 07crl9nil0 | 0. 04-.1 | <I. 00 | <II. 00 | XVIII. 00-20. 00 | - | VIII. 00-11 | - | - | - | - | 0. XXX | 0. XV |

| 07crl8nillnb | 0. 04-.1 | <I. 00 | <II. 00 | XVII. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. XXX | 0. XV | |

| 07Crl9nillti | 0. 04-.1 | <0. LXXV | <II. 00 | 17.00-20. 00 | - | IX. 00 ~ XIII. 00 | - | 4C-0. LX | 一 | 一 | 0.03 | 0. XV | |

| 022crl7nil2mo2 | <0. XXX | <I. 00 | <II. 00 | XVI. 00-18. 00 | II. 00-3. 00 | X. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. XV | |

| Non | Tensile MPA | Cedo MPA | Elong post Fractura /% | Effusio Energy KV2 / J | Brinell duritia numero | ||

| ecfigia | transversus | ecfigia | transversus | ||||

| non minus quam | plus | ||||||

| 10 | 335~475 | CCV | 25 | 23 | 40 | 27 | |

| 20 | 410~550 | CCXLV | 24 | 22 | 40 | 27 | |

| 12Crmo | 410~560 | CCV | 21 | 19 | 40 | 27 | CLVI HBW |

| 15Crmo | 440~640 | CCXCV | 21 | 19 | 40 | 27 | CLXX HBW |

| 12crlmo | 415~560 | CCV | 22 | 20 | 40 | 27 | CLXIII HBW |

| 12crlmov | CDLXX ~640 | CCLV | 21 | 19 | 40 | 27 | CLXXIX HBW |

| 12cr2mo | CDL ~ DC | CCLXXX | 22 | 20 | 40 | 27 | CLXIII HBW |

| 12Cr5Moi | 415~590 | CCV | 22 | 20 | 40 | 27 | CLXIII HBW |

| 12Cr5mont | CDLXXX ~640 | CCLXXX | 20 | 18 | 40 | 27 | - |

| 12Cr9Moi | 460~640 | CCX | 20 | 18 | 40 | 27 | CLXXIX HBW |

| 12cr9mont | 590-740 | CCCXC | 18 | 16 | 40 | 27 | |

| O7rl9nilo | MMDXX | CCV | 35 | CLXXXVII HBW | |||

| 07crl8nillnb | > DXX | CCV | 35 | - | CLXXXVII HBW | ||

| 07Crl9nillti | > DXX | CCV | 35 | - | - | CLXXXVII HBW | |

| 022crl7nil2mo2 | > CDLXXXV | CLXX | 35 | 一 | - | CLXXXVII HBW | |

| Nam ferro muro crassitudine minus 5mm tubus non durum experimentum | |||||||

HYDRAULICUS Test

Hydraulicorum test fuerit ferri fistularum unum. Maxime test pressura est XX MPA. Sub test pressura, in stabilization tempus non erit minus quam X s et leakage de ferro pipe non licet.

Test Flattening

Flattening test fuerit ad ferro pipe exterior diameter maior quam XXII mm

Flaring test

Quality altus carbon structural ferro et immaculatam (calor repugnans) ferro fistularum cum exterior diameter non plus quam LXXVI mm et murum crassitudine non plus quam VIII mm erit subiectum expanding non plus quam VIII mm erit subiectum ad expanding test. Flaring test fuerit ferri ex ad locus temperatus. Et exterior diameter flaring rate of sample post summo core taper est LX% de flaring occurrit in requisitis mensam VII. Nemo rimas aut rimas non licet in sample post flaring. Secundum ad Requirements de Demandrum et attendendum in contractus, in Alloy structural ferro potest etiam adhiberi ad expanding test.

Nondestructive Teste

Et ferro fistularum erit subiectum ad ultrasonic vitium deprehensio unus ex uno ad normam praescripta GB / T 5777-2008. Secundum ad Requirements Demander, aliud non-perniciosius probat potest addidit post negotium inter supplementum et demandam et indicavit in contractus.

Intergranular corrosio test

Intergranular corrosionis test fuerit conducted pro immaculatam (calor repugnans) ferro pipe. In test methodum erit secundum praescripta Chinese modum E in GB / T 4334-2008 et intergranular corrosio tendentia non licet post test.

Postquam negotium inter supplementum et ad Oremandrum, et attendendum in contractus, quod Demandra potest dici alium corrosio test modi.

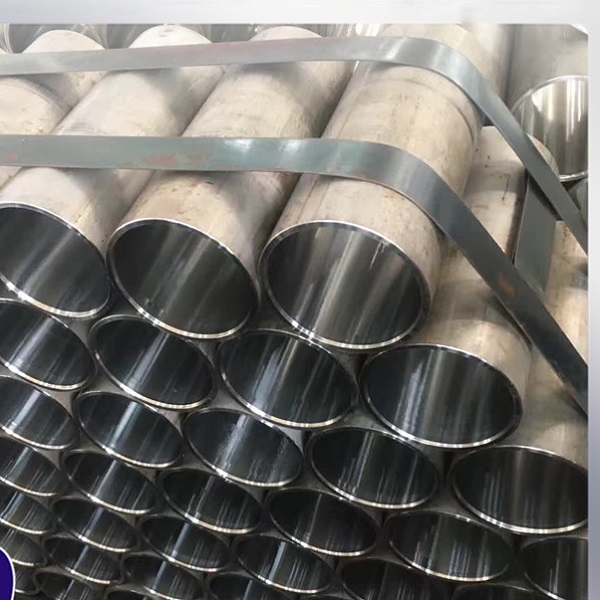

Oleum, Petrochemical, princeps pressura Boiler, specialis usu seamless fistulam Boiler Seamless Tube, Geological seamless Steel fistulam et oleum seamless fistulam.

Chemical component

| notus | Chemica component (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | NB + ta | S | P | |

| 15Crmo | 0.12 ~ 0.18 | 0,40 ~ 0.70 | 0,17 ~ 0.37 | 0.80 ~ 1.10 | 0,40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Mechanica res

| notus | Tensile MPA | Cedo MPA | Elongatio (%) |

| 15Crmo | CDXL ~ DCXL | CCXCV | 22 |