ASTM A335 P22 alloy steel pipe is an important industrial material with excellent properties such as high strength, high toughness, corrosion resistance and high temperature resistance. It is widely used in the fields of petroleum, chemical industry, electric power, nuclear industry, etc. This article will introduce the material, manufacturing process, performance characteristics and application fields of ASTM A335 P22 alloy steel pipe in detail, providing readers with a comprehensive and in-depth understanding.

The product should comply with TSG D7002 pressure piping component type test rules.

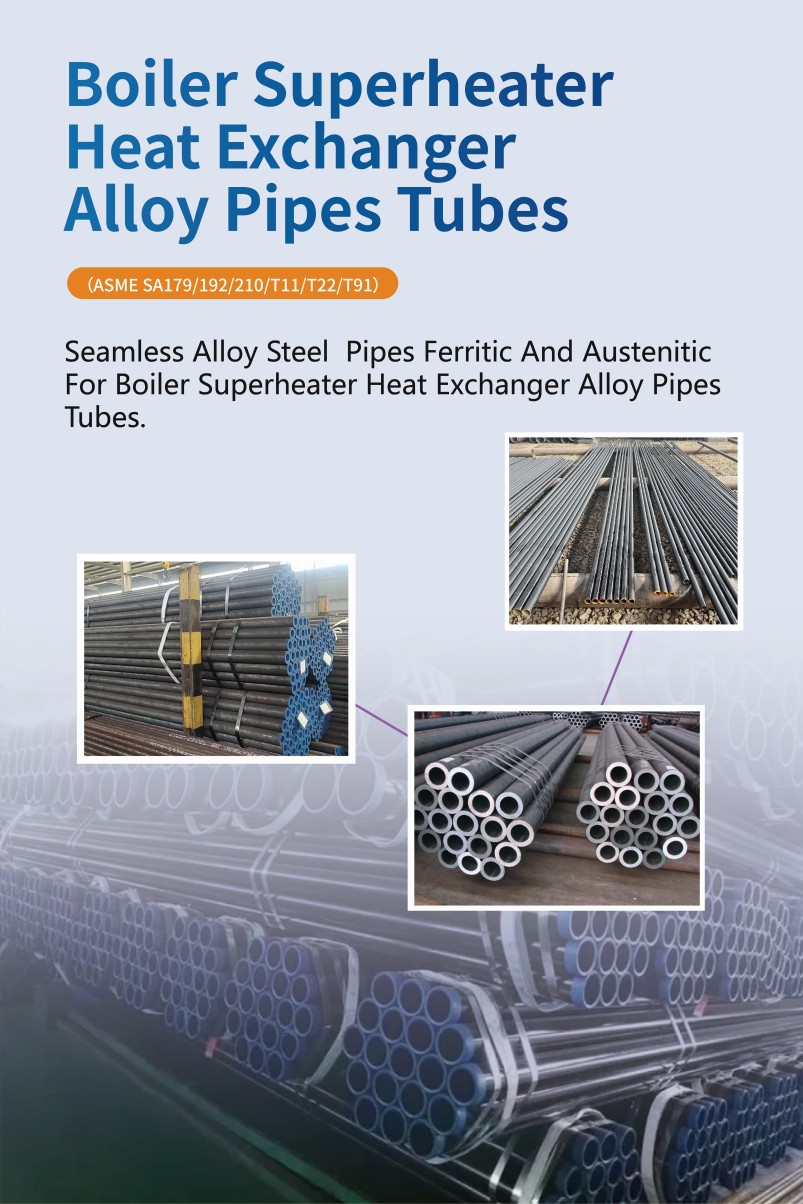

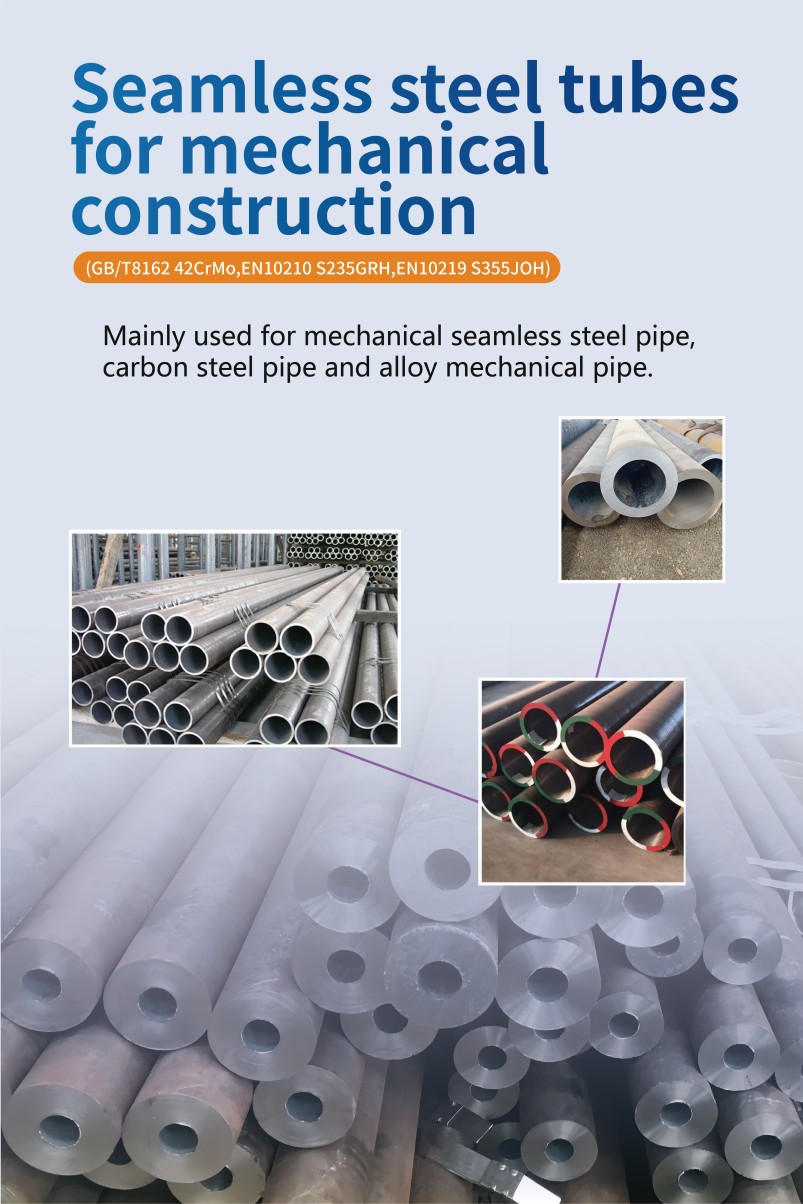

Implementation standard: ASTMA335/A335M high temperature iron tree alloy steel seamless steel pipe specification

Product specifications: outer diameter 21.3mm~762mm, wall thickness 2.0~140mm.

Chemical composition: carbon: 0.05~0.14, manganese: 0.30~0.60, phosphorus: ≤0.025, sulfur ≤0.025, silicon: ≤0.50, chromium: 1.90~2.60, molybdenum: 0.87~1.13. Nickel: ≤0.50

Tensile strength: ≥415MPa, yield strength: ≥205, elongation: ≥30, hardness: less than or equal to 163HBW

Production method: cold drawing, hot rolling, hot expansion. Delivery status: heat treatment.

First, let's discuss the material of ASTM A335 P22 alloy steel pipe. This steel pipe uses high-quality carbon structural steel or alloy structural steel as the main raw material and is made through precise cold drawing or hot rolling process. The precise control of carbon content, alloy elements and trace elements in the steel pipe ensures the high strength and toughness of the steel pipe. In addition, the corrosion resistance of ASTM A335 P22 alloy steel pipe is also excellent, and it can maintain its performance and service life for a long time in harsh environments.

Next, let's learn about the manufacturing process of ASTM A335 P22 alloy steel pipe. The manufacturing process mainly includes key links such as smelting, rolling and heat treatment. During the smelting process, the raw materials are heated to a molten state and the necessary alloy elements are added to obtain the required chemical composition and alloy structure. During the rolling process, the dimensional accuracy, surface quality and mechanical properties of the steel pipe are ensured by precisely controlling parameters such as rolling temperature, speed and deformation. Finally, the heat treatment link helps to eliminate the residual stress inside the steel pipe and improve its stability and durability.

The performance characteristics of ASTM A335 P22 alloy steel pipe are also one of the reasons for its popularity. First of all, the steel pipe has high strength and toughness, can withstand high pressure and impact, and meet the needs of various complex working conditions. Secondly, it has excellent corrosion resistance and can resist the erosion of various chemical substances to ensure long-term stable operation. In addition, ASTM A335 P22 alloy steel pipe also has good high temperature resistance and can maintain stable mechanical and chemical properties under high temperature environment.

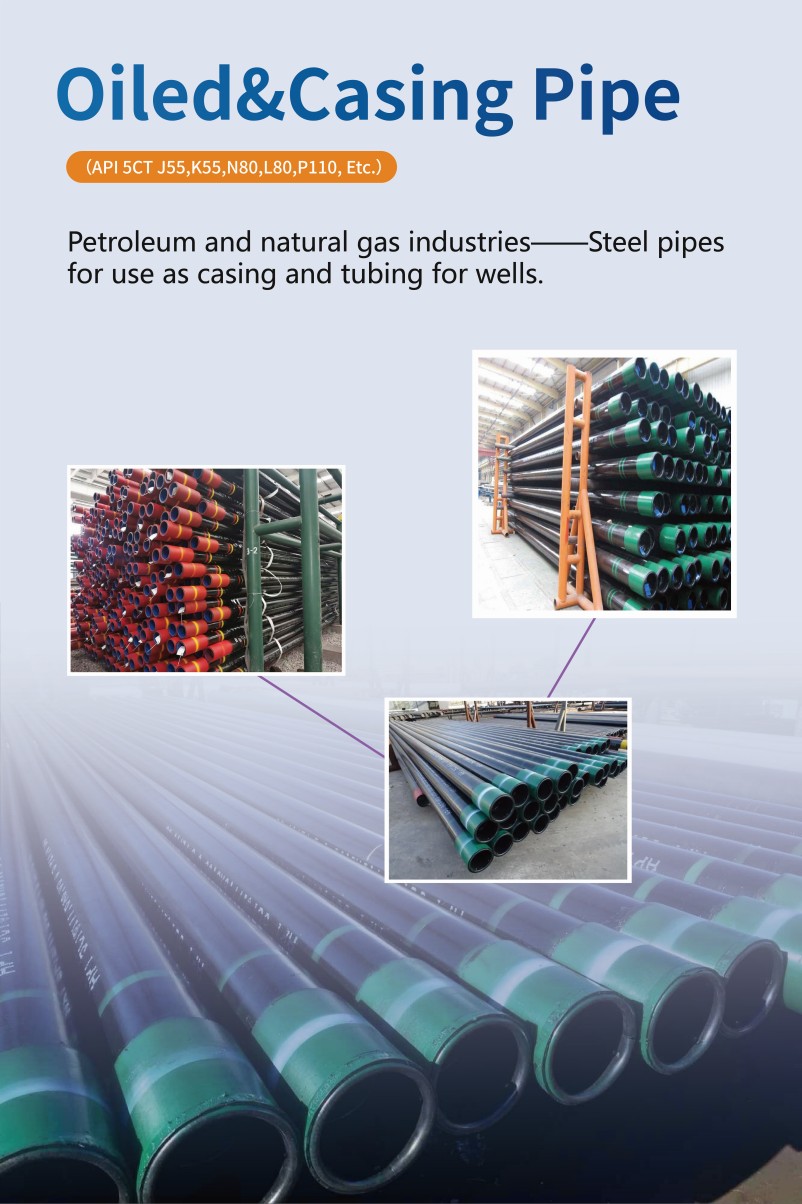

It is precisely because of these excellent performance characteristics that ASTM A335 P22 alloy steel pipe has been widely used in many fields. In the field of petroleum and chemical industry, the steel pipe is used to manufacture high temperature and high pressure pipelines and equipment to ensure the safety and stability of the production process. In the field of power, ASTM A335 P22 alloy steel pipe is widely used in key equipment such as boilers and superheaters, withstanding high temperature and high pressure steam and hot water, providing reliable guarantee for power production. In addition, in the field of nuclear industry, the steel pipe also plays an important role in the manufacture of pipes and containers in nuclear reactors to ensure the safe use of nuclear energy.

In addition to the above application areas, ASTM A335 P22 alloy steel pipe can also be customized according to customer needs to meet the use requirements in specific scenarios. For example, by adjusting the parameters such as wall thickness, diameter and length of the steel pipe, it can meet the needs of different projects. At the same time, the steel pipe can also be surface treated according to customer needs, such as spraying anti-corrosion coating, galvanizing, etc., to improve its corrosion resistance and service life.

ASTM A335 P22 alloy steel pipe, as an industrial material with excellent performance, plays an important role in many fields. With the continuous advancement of technology and the continuous expansion of application fields, we have reason to believe that ASTM A335 P22 alloy steel pipe will continue to contribute to industrial development in the future.

Post time: Mar-10-2025