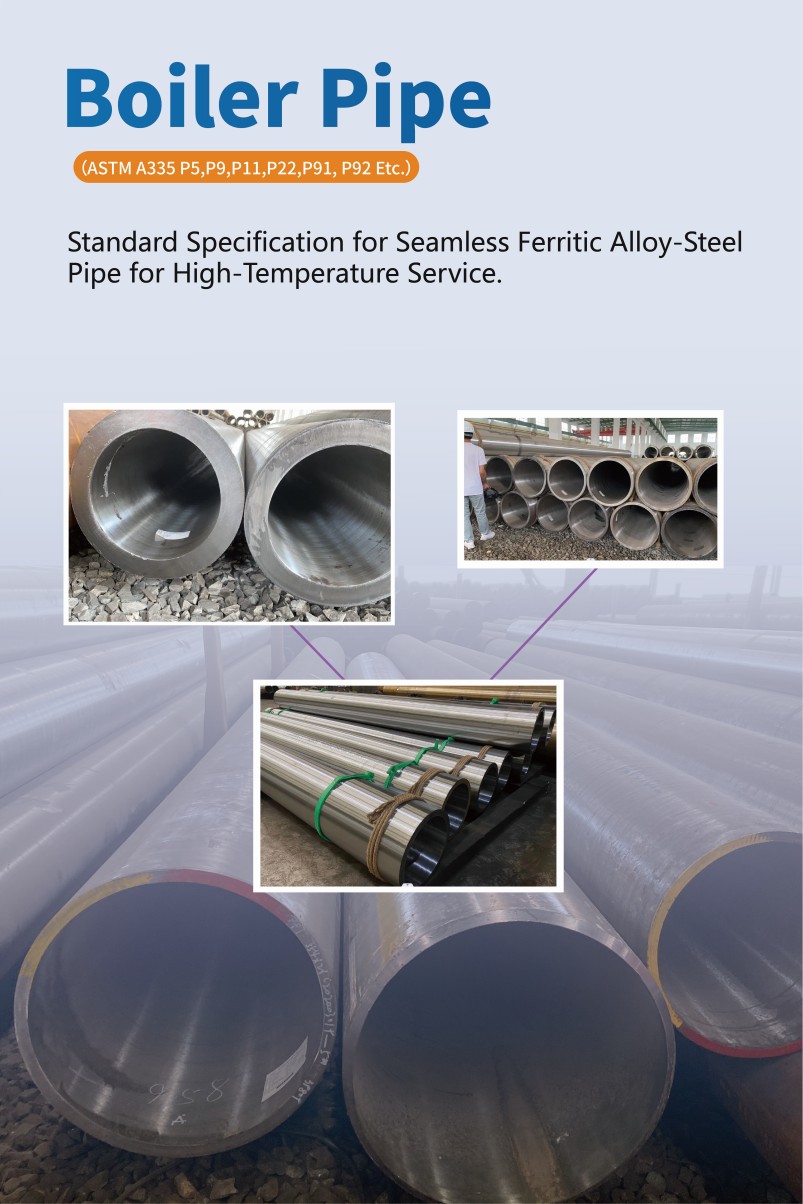

Seamless steel pipe GB5310 15CrMoG high-pressure boiler tube: professional-grade high-temperature and high-pressure seamless steel pipe

In the power, petrochemical, energy and other industries, the safety and durability of high-pressure boiler tubes directly affect the operating efficiency of equipment. GB5310 15CrMoG high-pressure boiler seamless steel pipe, with its excellent performance and strict quality control, has become an ideal choice for high-temperature and high-pressure working conditions.

The product strictly follows the GB5310 standard, using high-quality 15CrMoG chromium-molybdenum alloy steel (Cr: 1.0-1.5%, Mo: 0.45-0.60%), and is made of seamless structure through hot rolling and cold drawing process, with both high strength (tensile strength ≥ 440MPa) and temperature resistance (applicable temperature ≤ 580℃). Its anti-oxidation and anti-creep properties are outstanding, and it can withstand high-pressure steam and flue gas corrosion for a long time, and its service life is more than 30% higher than that of ordinary steel pipes. Ultrasonic flaw detection, eddy current detection and water pressure test are performed throughout the process to ensure zero cracks and no leakage, and the safety level reaches the industry-leading level.

Multi-scenario coverage, precise matching of needs

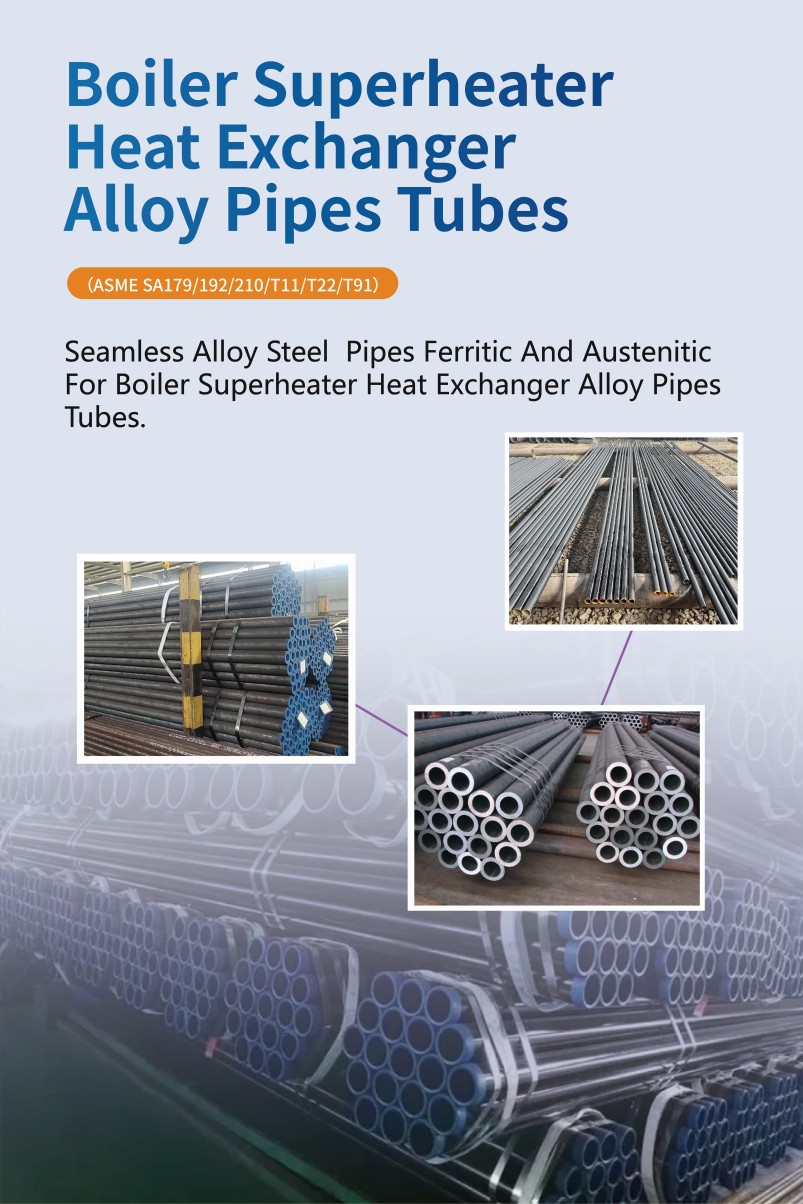

Designed for key components such as power station boilers, superheaters, and reheaters, it is suitable for supercritical and subcritical units and waste heat recovery systems. It is also widely used in high-temperature and high-pressure pipeline projects in the fields of petrochemicals, coal chemical industry, and cogeneration. It supports flexible customization of outer diameters of 25-762mm and wall thicknesses of 2.5-120mm to meet the installation requirements of complex working conditions, helping customers reduce maintenance costs and improve energy utilization.

Post time: Mar-28-2025