In order to ensure that the quality of seamless steel pipe products meets the standards, comprehensive testing of various data such as appearance, size, material, chemical composition, mechanical properties, process performance, and non-destructive inspection of seamless steel pipes is essential. Below we will briefly introduce the testing standards that mainly affect the quality of seamless steel pipes.

First, appearance inspection is the first step. The surface of seamless steel pipes should be free of bubbles, scratches, discoloration, cracks and other defects. These defects not only affect its aesthetics, but may also cause various problems during use of the product and even cause safety hazards. Therefore, through appearance inspection, products with poor quality can be initially screened out.

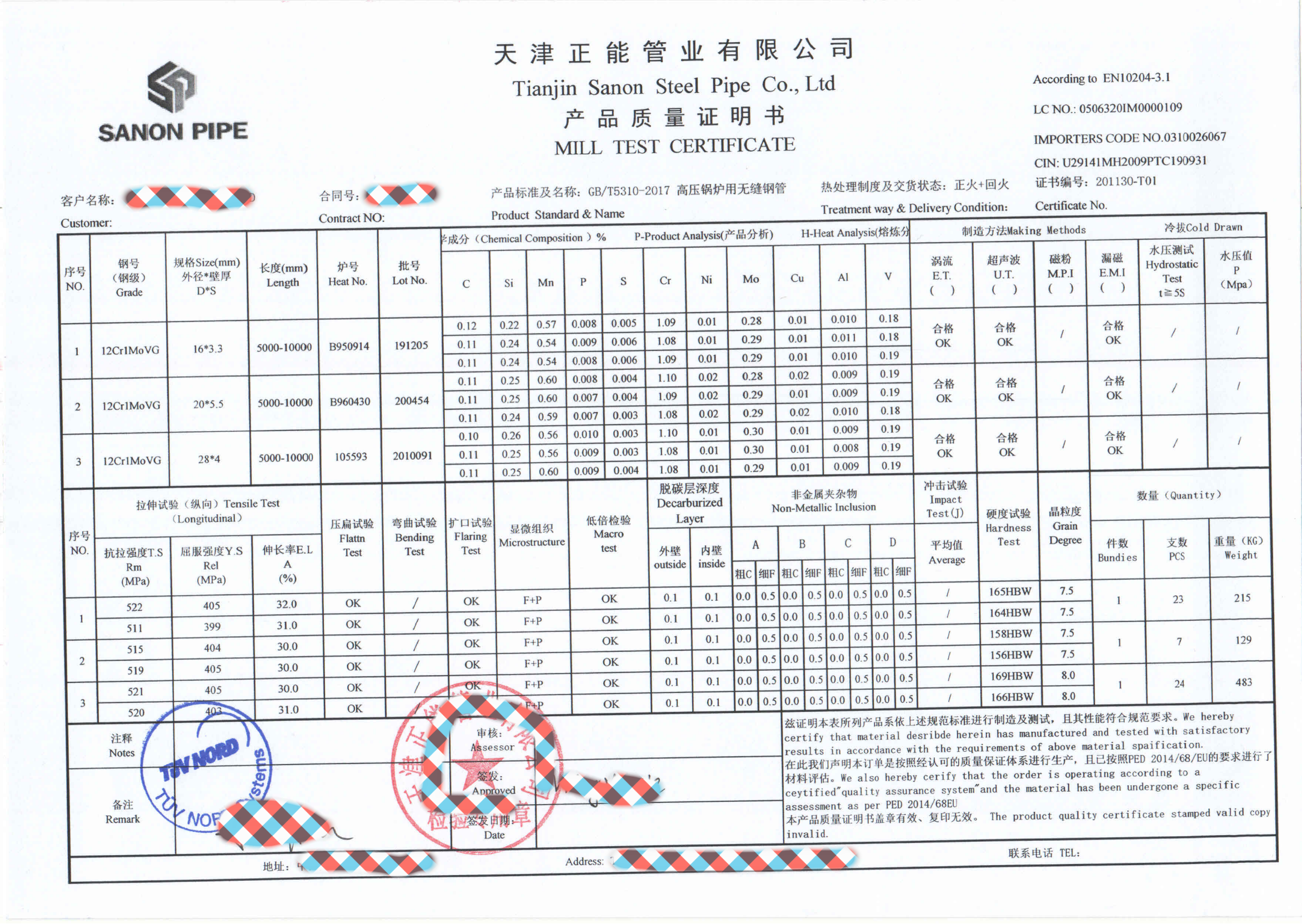

Next is size inspection. The dimensional accuracy of seamless steel pipes directly affects its performance. Therefore, key parameters such as diameter, wall thickness, and length of steel pipes must be strictly measured and controlled. Only when these dimensional parameters meet the standard requirements can the stability of the steel pipe in application be guaranteed.

Material testing is also a key link. The material of seamless steel pipe usually involves a variety of metal elements, such as carbon, manganese, silicon, phosphorus, etc. The proportion of these elements directly affects the mechanical properties and process performance of steel pipes. Therefore, raw materials must undergo strict chemical composition testing to ensure that they meet relevant standards.

Mechanical properties and process performance testing are also essential links. These tests mainly include tensile test, impact toughness test, hardness test, expansion test, etc. These tests can fully reflect the mechanical properties and processing properties of steel pipes. Through these detection data, manufacturers can choose appropriate production processes for different application scenarios of the product to ensure product performance.

Finally, non-destructive testing is also an important means of quality testing for seamless steel pipes. Non-destructive testing methods such as radiographic testing, ultrasonic testing, and magnetic particle testing can detect defects such as cracks and inclusions inside and on the surface of steel pipes. These defects are difficult to detect during ordinary inspection, but they may have a serious impact on the service life of the steel pipe. Therefore, through non-destructive testing, the inherent quality of seamless steel pipe products can be further ensured.

In short, in order to ensure the quality of seamless steel pipe products meets the standards, comprehensive testing of various data is an indispensable link. These testing standards not only involve basic parameters such as appearance, size, and material, but also cover many aspects such as mechanical properties, process performance, and non-destructive testing. Through these comprehensive tests, the quality level of seamless steel pipe products can be comprehensively evaluated to ensure their safety and stability during use.

Post time: Nov-08-2023