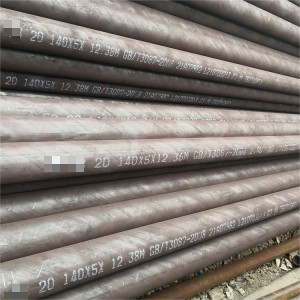

There are two types of seamless steel pipes: hot-rolled and cold-rolled (dial) seamless steel pipes.

Hot-rolled seamless steel pipes are divided into general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, petroleum cracking pipes, geological steel pipes and other steel pipes.

In addition to general steel pipes, low and medium pressure boiler steel pipes, high pressure boiler steel pipes, alloy steel pipes, petroleum cracking pipes, and other steel pipes, cold-rolled (dial) seamless steel pipes also include carbon thin-walled steel pipes, alloy thin-walled steel pipes, profiled steel pipes, etc. .

The outer diameter of hot-rolled seamless pipe is generally greater than 32mm, and the wall thickness is 2.5-75mm. The diameter of cold-rolled seamless steel pipe can reach 6mm, and the wall thickness can reach 0.25mm. The outer diameter of thin-walled pipe can reach 5mm, and the wall thickness is less than 0.25mm. Cold rolling has higher dimensional accuracy than hot rolling.

Seamless steel pipes for general use: are made of high-quality carbon steel such as 10, 20, 30, 35, 45, 16Mn, 5MnV and other low-alloy structural steels or 40Cr, 30CrMnSi, 45Mn2, 40MnB and other alloy steels that are hot-rolled or cold-rolled.

10, 20 and other low carbon steel seamless pipes are mainly used for fluid conveying pipelines. Seamless tubes made of medium carbon steel such as 45 and 40Cr are used to manufacture mechanical parts, such as stressed parts of automobiles and tractors. Generally, seamless steel pipes are used to ensure strength and flattening tests. Hot-rolled steel pipes are delivered in a hot-rolled or heat-treated state; cold-rolled steel pipes are delivered in a heat-treated state.

Post time: Dec-29-2022