In the current seamless steel pipe market, customer needs are becoming increasingly urgent, especially for orders with a small minimum order quantity. How to meet these customer needs has become our top priority. Faced with this situation, we actively communicate with major factories and strive to integrate spot resources of different materials and specifications to ensure that customers can get the required products in the shortest time.

First, we will understand the specific needs of customers in detail, including information such as the material, specification, and quantity of the required steel pipe. After mastering this information, we will quickly contact our supply chain partners to seek spot inventory to ensure that we can provide products that meet customer requirements. At the same time, we will also flexibly adjust our procurement strategy to meet different customer needs, consolidate small batch orders, and meet customer procurement needs.

In addition, in order to improve delivery efficiency, we will also strengthen internal coordination to ensure efficient operation in production and logistics. We are well aware that timely delivery is not only a commitment to customer trust, but also an important basis for maintaining good business relationships. Therefore, we will continue to maintain flexibility and agility, and strive to provide customers with the best solutions so that they can get timely support and services in urgent needs. Through such efforts, we believe that we can stand out in the fierce market competition and win more customers' trust and cooperation.

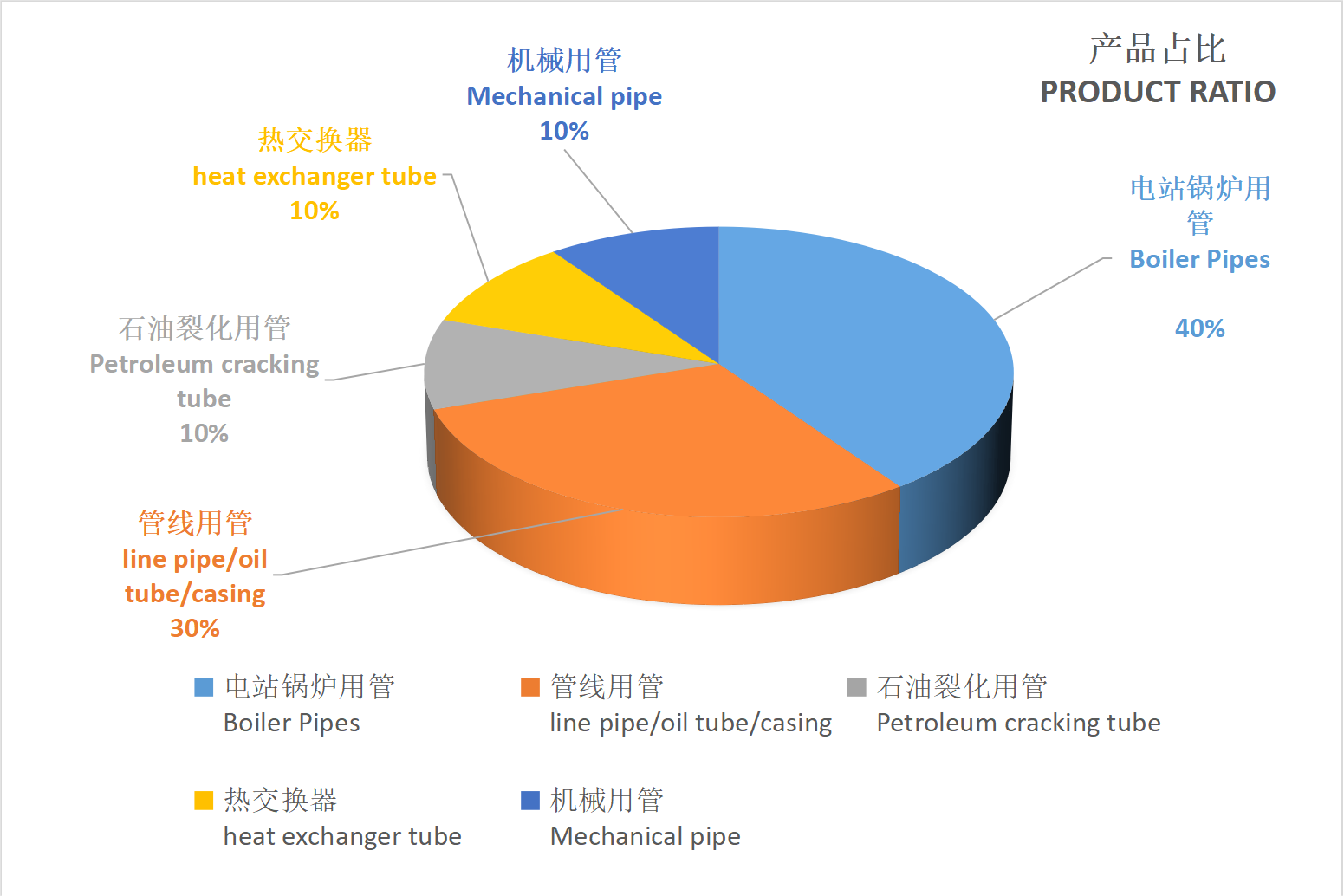

Sanonpipe main seamless steel pipes include boiler pipes, fertilizer pipes, oil pipes, and structural pipes.

1.Boiler Pipes 40%

ASTM A335/A335M-2018: P5, P9, P11, P12, P22, P91, P92; GB/T5310-2017: 20g, 20mng, 25mng, 15mog, 20mog, 12crmog, 15crmog, 12cr2mog, 12crmovg; ASME SA-106/ SA-106M-2015: GR.B, CR.C; ASTMA210(A210M)-2012: SA210GrA1, SA210 GrC; ASME SA-213/SA-213M: T11, T12, T22, T23, T91, P92, T5, T9 , T21; GB/T 3087-2008: 10#, 20#;

2.line pipe 30%

API 5L: PSL 1, PSL 2;

3.Petrochemical pipe 10%

GB9948-2006: 15MoG, 20MoG, 12CrMoG, 15CrMoG, 12Cr2MoG, 12CrMoVG, 20G, 20MnG, 25MnG; GB6479-2013: 10, 20, 12CrMo, 15CrMo, 12Cr1MoV, 12Cr2Mo, 12Cr5Mo, 10MoWVNb, 12SiMoVN b;GB17396-2009:20, 45, 45Mn2;

4.heat exchanger tube 10%

ASME SA179/192/210/213 : SA179/SA192/SA210A1.

SA210C/T11 T12, T22.T23, T91. T92

5.Mechanical pipe 10%

GB/T8162: 10, 20, 35, 45, Q345, 42CrMo; ASTM-A519:1018, 1026, 8620, 4130, 4140; EN10210: S235GRHS275JOHS275J2H; ASTM-A53: GR.A GR.B

Post time: Oct-24-2024