After the contract is signed, we start planning procurement, starting from the billet to control the quality, production cycle and delivery period of the steel pipe.

1. Billet procurement→

2. After the pipe is threaded, the first cold drawing is carried out, followed by heat treatment, and then the second cold drawing. Measure the wall thickness, outer diameter, take photos of the entire steel pipe, and send the production process and production progress to the customer in real time.

3. Perform spraying and length measurement. At this time, the customer will send a third party to inspect the finished product, including chemical composition, outer diameter, wall thickness, and various inspections of sealing.

4. After the inspection is passed, we will package and ship the steel pipe.

We will report and shoot the control and supervision of the entire production process to customers in real time, so that customers can rest assured and worry-free. There is such a team that helps you control the entire process. Please rest assured to give the entire order to us.

The first step of cooperation will give customers 100% peace of mind and peace of mind. Welcome your inquiries and messages.

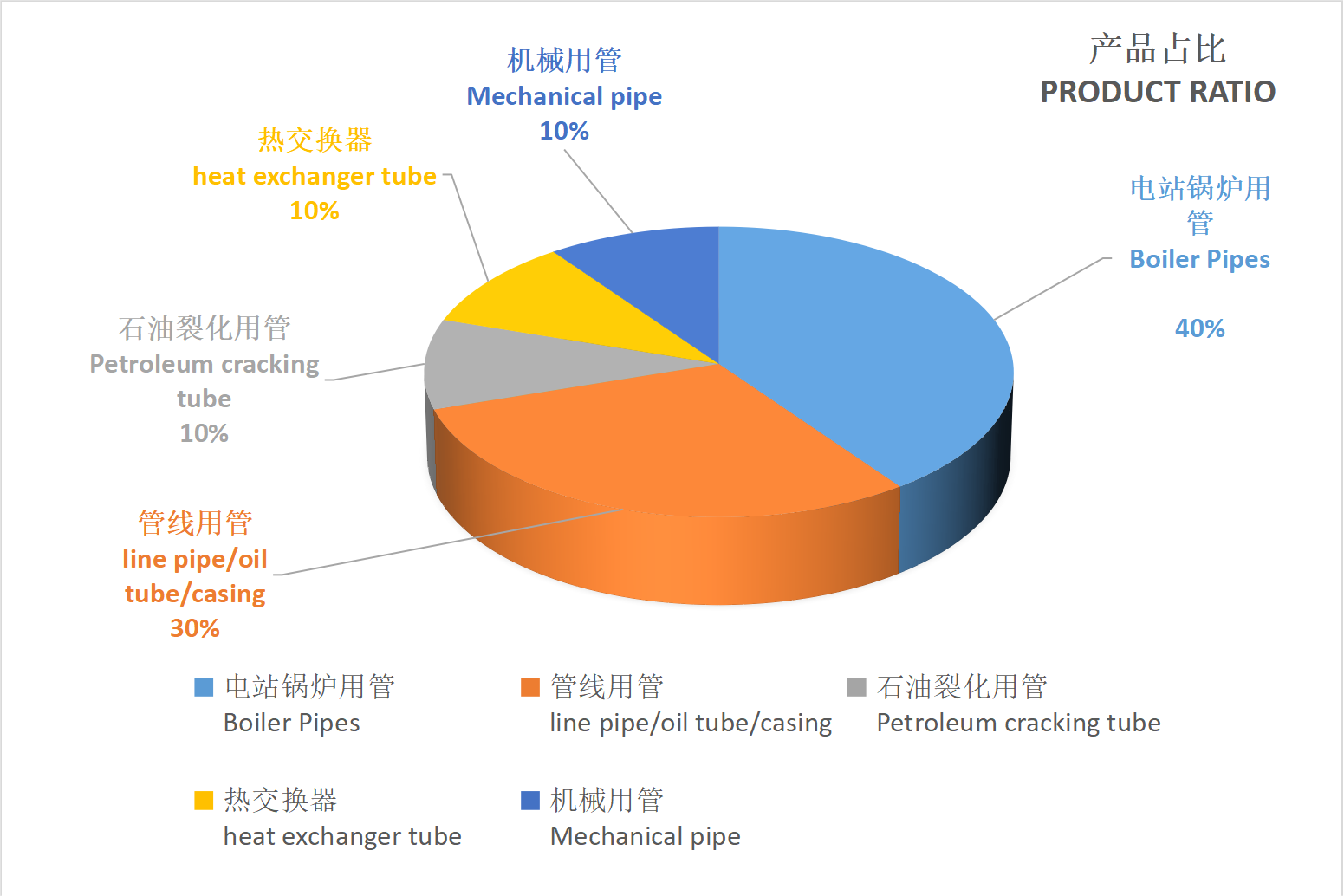

Sanon Pipe Industry's main products:

Boiler pipes, fertilizer pipes, oil pipes, and structural pipes.

Zhengneng Pipe Industry is committed to providing reliable and valuable project and operation solutions to customers and partners around the world, including the boiler industry, oil and gas industry, water conservancy, mining, energy industry, and mechanical equipment industry. Products are sold to Southeast Asia, the Middle East, North America, and South America.

Today, we will introduce our company's main products. Our company's main products are: Boiler Pipes account for 40%; line pipe accounts for 30%; Petrochemical pipe accounts for 10%; heat exchanger tube accounts for 10%; Mechanical pipe accounts for 10%.

1.Boiler Pipes 40%

ASTM A335/A335M-2018:P5、P9、P11、P12、P22、P91、P92;GB/T5310-2017:20g、20mng、25mng、15mog、20mog、12crmog、15crmog、12cr2mog、12crmovg;ASME SA-106/SA-106M-2015:GR.B、CR.C;ASTMA210(A210M)-2012:SA210GrA1、SA210 GrC;ASME SA-213/SA-213M:T11、T12、T22、T23、T91、P92、T5、T9、T21;GB/T 3087-2008:10#、20#;

API 5L:PSL 1、PSL 2;

3.Petrochemical pipe 10%

GB9948-2006:15MoG、20MoG、12CrMoG、15CrMoG、12Cr2MoG、12CrMoVG、20G、20MnG、25MnG;GB6479-2013:10、20、12CrMo、15CrMo、12Cr1MoV、12Cr2Mo、12Cr5Mo、10MoWVNb、12SiMoVNb;GB17396-2009:20、45、45Mn2;

4.heat exchanger tube 10%

ASME SA179/192/210/213 : SA179/SA192/SA210A1.

SA210C/T11 T12, T22.T23, T91. T92

5.Mechanical pipe 10%

GB/T8162 : 10、20、35、45、Q345、42CrMo;ASTM-A519:1018、1026、8620、4130、4140;EN10210:S235GRHS275JOHS275J2H;ASTMA53:GR.A GR.B

Post time: Sep-09-2024