Zithunzi zachitsulo zosawoneka: chitoliro chachitsulo chosawoneka bwino chimakhala ndi piltot billet ndi zotupa mu chubu choyipa, kenako ndikuwotcha kapena kuzizira. Zinthu zomwe zimapangidwa ndi chitsulo chapamwamba kwambiri monga 10,20, 30, 35,45, zitsulo zotsika ngati11, 5mnc kapena alloy chitsulo monga 40cr, 30cmni, 45mn2, 40mm ndi kugudubuzika kotentha kapena kugudubuzika. Mapaipi opanda pake opangidwa ndi chitsulo chotsika ngati 10 ndi 20 amagwiritsidwa ntchito makamaka potumiza madzimadzi.

Nthawi zambiri, kupanga mapaipi achitsulo opanda zisoti kumagawidwa m'mitundu iwiri: Kujambula kozizira kujambula ndi njira yoyenda. Chotsatirachi ndikuwunika mwachidule momwe makompyuta amawonera pamapaipi achitsulo osawoneka bwino ndi mapaipi achitsulo osawoneka:

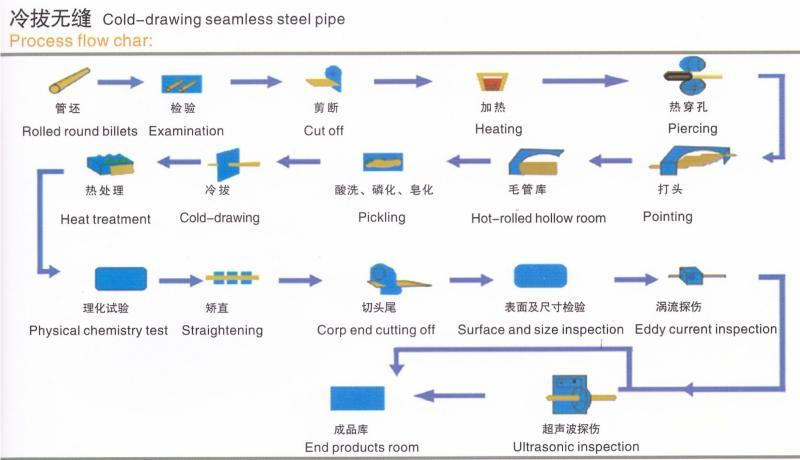

Kukongoletsa (kuzizira) dongosolo lachifumu losakhala: Kukonzekera kwa chubu

Ma billet ozizira ozizira achitsulo ayenera kuyamba kumenyedwa mosalekeza, ndipo kuyesayesa kwamphamvu kuyenera kuchitika pambuyo popepuka. Ngati palibe kuyankha pansi, chubu chozungulira muyenera kudulidwa ndi makina odulira ndikudula ma billets ndi kutalika kwa mita imodzi. Kenako lowetsani njira yopangira. Mankhwala ayenera kusaka ndi madzi acidic. Pakuthana, samalani ngati pali thovu lalikulu pansi. Ngati pali thovu lalikulu, zikutanthauza kuti chitoliro chachitsulo sichimakwaniritsa miyezo yolingana.

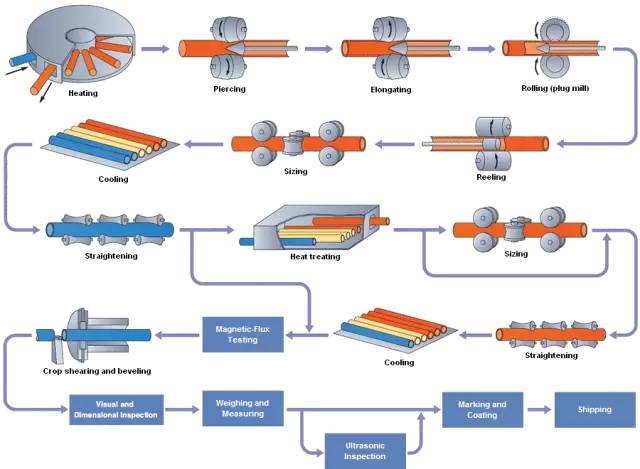

Kutentha (Kutalika) Matumba achitsulo osawoneka bwino: Kutentha kwa mphika → Kuchepetsa (kapena kuwongolera)

Kuyenda kotentha, monga dzinalo, monga momwe dzina lake limatanthawuza, limakhala ndi kutentha kwambiri kwa chidutswa chofuula, kotero kukana kufooka ndikochepa ndipo kuchuluka kwakukulu kumatheka. Mapaipi operekera zitsulo zosawoneka bwino nthawi zambiri amakhala otentha komanso otenthedwa asanabadwe. Chipilala cholimba ndi zofooka zapamwamba zimachotsedwa, kudula mu kutalika kofunikira, ndikukhoma kwa nkhope yomaliza kumapeto kwa chubu, kenako ndikutumiza ku ng'anjo yotentha chifukwa chotenthetsera ndikuzimitsa. Ngakhale akupanga, zimazungulira ndikuyenda mosalekeza mosalekeza. Mothandizidwa ndi odzigudubuza ndi mutu, mkhola pang'onopang'ono umasiyanasiyana mkati mwa chubu, omwe amatchedwa chubu choyipa. Chitalowetsidwacho chikachotsedwa, chimatumizidwa ku makina opangira chubu cha chubu chopitilira, kenako makulidwe amasinthidwa ndi makina owongolera, ndipo mainchesi amatsimikiziridwa ndi makina ochitira zinthu kuti akwaniritse zofuna zazolingana. Pambuyo poyendetsa mankhwala otentha, kuyesa kwa mankhwalawa kuyenera kuchitika. Ngati mulifupi wa mankhwalawo ndi akulu kwambiri, ayenera kukhala owongoledwa ndikukonzedwa, ndipo pamapeto pake analemba ndi kuloledwa.

Kufanizira kwa zojambula zozizira komanso kusinthasintha kotentha: Njira yowombera yozizira imakhala yovuta kwambiri kuposa njira yotentha, koma mawonekedwe, komanso kukula kwa mbale zachitsulo, ndipo makulidwe amapezekanso.

Kukula kwake: m'mimba yakunja yopanda chitoliro chopanda chofunda nthawi zambiri zimakhala zokulirapo kuposa 32mm, ndipo makulidwe makulidwe ndi 2.5-200mm. Mawonekedwe akunja ozizira ozizira amatha kukhala ndi 6mm, khoma limatha kukhala ndi 0,25mm, ndipo kulondola kwa khoma.

Maonekedwe: Ngakhale khoma makulidwe a chitoliro chozizira kwambiri nthawi zambiri chimakhala chocheperako kuposa chitoliro chachitsulo chosawoneka bwino, pansi sichikuwuma kwambiri, ndipo m'mimba mwake mulibe malo ambiri.

Mapaipi obwezeretsedwa: Mapazi achitsulo otentha amaperekedwa mu dziko lotentha kapena kutentha, ndipo mapaipi achiwiri ozizira amaperekedwa pamtunda wa kutentha.

Post Nthawi: Aug-21-2024