Seamless Steel Steel Zvinyorwa: Seamless Steel Pombi yakagadzirwa ne Simbi Ingot kana Solid Tube Billet neSpforlet mune yakaoma Tube, uye ipapo inopisa yakatenderera, kutonhora kukwira kana kutonhora kutonhora. Izvo zvinyorwa zvinowanzogadzirwa nemhando yepamusoro carbon simbi senge gumi,20, 30, 35,45, yakaderera alloy yakarongedzwa simbi senge16mn. Pipisi yeSeamless yakagadzirwa neyakaderera carbon simbi yakadai segumi uye makumi maviri inonyanya kushandiswa pombi dzekutumira dzemvura.

Kazhinji, maitiro ekugadzira emabhegi eSimbi akapatsanurwa kuita marudzi maviri: kutonhora kudhirowa maitiro uye kupisa kunopisa maitiro. Izvi zvinotevera kuongororwa kwekuyerera kwekuyerera kwekutonhora kwekutonhora-kusanzwisisika simbi mipimo uye inopisa-yakakungurutswa seamless simbi mapipi.

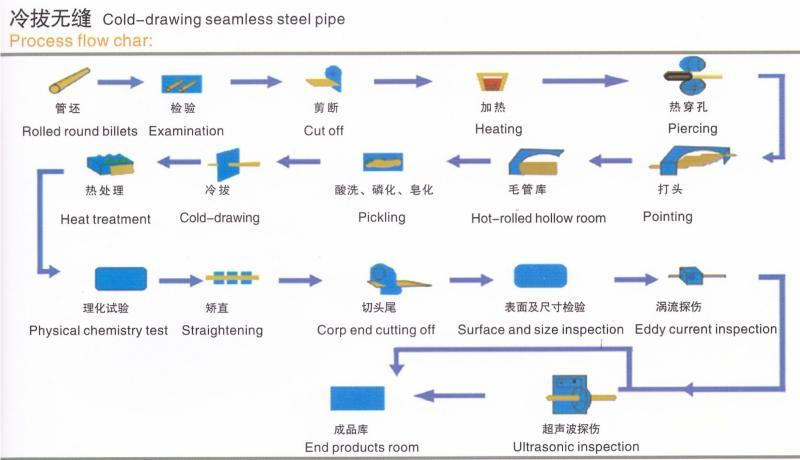

Kutonhora-kukwezva (kutonhora-kwakapetwa) seamless simbi pombi yekugadzirisa

Kutonhora-kwakadzvanywa seamless Steel Bille Billets inofanira kutanga kuiswa pasi pe3-roll inoenderera ichirovera, uye kuronga bvunzo kunofanirwa kuitwa mushure mekuumbwa. Kana pasina mhinduro yekupaza pamusoro, iyo kutenderera tube inofanira kutemwa nemuchina wekucheka uye akacheka kuita midziyo ine kureba kwemamita imwe. Wobva waisa maitiro ekuwedzera. Annealing anofanira kutorwa neakari yemvura. Panguva yekutora, teerera kune kana paine huwandu hwakawanda hwemabubu pamusoro. Kana paine huwandu hukuru hwemabubbles, zvinoreva kuti kunaka kweiyo jira yesimbi haina kusangana nemitemo inoenderana.

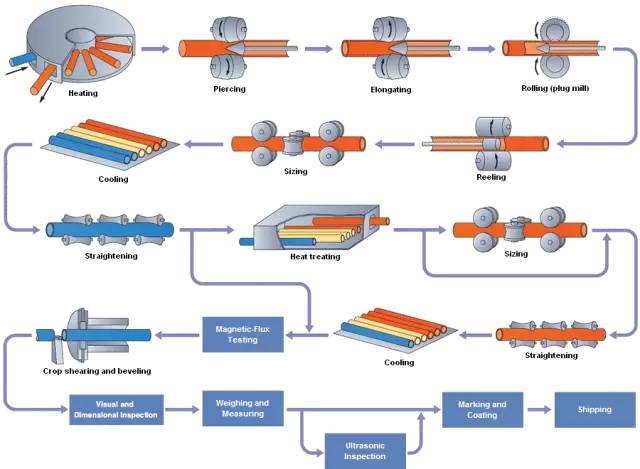

Inopisa-yakawedzera

Kutsvaira kupisa, sezita rinoreva, rine tembiricha yakanyanya yeiyo yakakwenenzverwa chidimbu, saka kudzikisira kwehurongwa idiki uye huwandu hwakakura hwekuita hunogona kuwanikwa. Iyo yekuzvitakura mamiriro ekupisa-yakamanikidzwa seamless Simbi mapepa anowanzo kupisa-yakaipisa uye kupisa-kurapwa usati waendesa. Iyo yakasimba tube inoongororwa uye yakaremara inobviswa, yakatemwa murefu kureba, yakatarisana nechiso chekupedzisira chemugumo wehubhu, uye wobva watumirwa kuchiripo chekupisa uye chakapetwa uye chakazara pane perforator. Paunenge uchitsauka, zvinotenderera uye unofamba uchienderera mberi. Pasi pechiitiko cherudzi rweanomuka uye musoro, iyo cavity zvishoma nezvishoma mafomu mukati mehubhu, iyo inonzi iyo yakaoma tube. Pashure pokunge chubhu chabviswa, chinotumirwa kune otomatiki muchina kuenderera mberi nekuenderera mberi, uyezve madziro akakomberedzwa nemushini wedare, uye dhayamita inotsanangurwa nemuchina wekurongedza kuti usangane nezvinodiwa zvekufunga. Mushure mekurapa kunopisa kurapwa, kuedza kwekufungidzira kunofanira kuitwa. Kana iyo fungidziro yekusagadzikana yakakura kwazvo, inofanira kurongerwa uye yakagadziriswa, uye pakupedzisira yakanyorwa uye kuiswa mukuchengetedza.

Kuenzanisa kwekutonhora kwekudhirowa uye kuenderera mberi kwekutonhora maitiro

Saizi: Iyo yekunze dhayiyano yeiyo inopisa-yakakungurutswa yemusungwa pombi kazhinji yakakura kupfuura 32mm, uye madziro madziro ari 2,5-200mm. Iyo yekunze dhaya yechando

Chitarisiko: Kunyangwe madziro akatonhorera seyekuchengeterwa simbi pombi inowanzoita seyekupisa-yakakwenenzverwa-yakadzvanywa simbi pombi

Nzvimbo yekuendesa: inopisa-yakakungurutswa mapepa anoiswa mune inopisa-yakatenderera kana kupisa-kurapwa mamiriro, uye inotonhora-yakakurirwa masimbi mapipi anounzwa munzvimbo inoitirwa kupisa.

Kutumira Nguva: Aug-21-2020