Likarolo tse chesang tse nang le mokhoa oa ho hloka letsoho tsa tse se nang alloy le li-steen tse ntle

| Tloaelo: BSse10210-1-2006 | Alloy kapa che: eseng |

| Sehlopha sa sehlopha: S235GRH, S235GRH, S275Joh, S275J2h, S3557O, S355J2h | Kopo: Sebopeho |

| Botenya: 1 - 100 mm | Phekolo ea holimo: E le tlhokahalo ea bareki |

| Bophara ba kantle (ho potoloha): 10 - 1000 mm | Mokhoa: ho chesa kapa ho bata |

| Bolelele: Bolelele ba bolelele kapa bolelele bo sa sebetseng | Phekolo ea mocheso: ho kopanya / ho hokahanya / ho fokotsa khatello ea maikutlo |

| Sebopeho sa karolo: ho potoloha | Pipe e khethehileng: Popi e teteaneng |

| Sebaka sa Tšimoloho: China | Karabelo: sebopeho sa mochini, sebopeho se akaretsang |

| Setifikeiti: Iso9001: 2008 | Teko: Ect / UT |

E sebelisoa haholo bakeng sa sebopeho sa mochini, sebopeho se akaretsang.

S235GRH, S27GRH, S275Joh2h, S3555Joh, S355J2h

| Keletso | Deoxegeted Thaepa a | % Mass, boholo | |||||||

| Lebitso la Steel | Steel Nmber | C Bokhoni bo qotsitsoeng leboteng le leng | Si | Mn | P | S | NBC | ||

| ≤ 40 | > 40 ehlile 120 | ||||||||

| S235JRH | 1.0039 | FN | 0.17 | 0.20 | - | 1.40 | 0.040 | 0.040 | 0.009 |

| S275j0h | 1.0149 | FN | 0.20 | 0.22 | - | 1.50 | 0.035 | 0.035 | 0.009 |

| S2755J2h | 1.0138 | FF | 0.20 | 0.22 | - | 1.50 | 0.030 | 0.030 | - |

| S355j0h | 1.0547 | FN | 0.22 | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 0.009 |

| S355J2h | 1.0576 | FF | 0.22 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | - |

| S355k2h | 1.051212 | FF | 0.22 | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | - |

| Tlhaloso ea mokhoa oa Deoxidation e tjena: FN = Steel e belang ha e lumelloe FF = Steel o bolaile ka botlalo likarolo tse fumanehang ka bongata ka chelete e lekaneng ho tlama ho ba teng ho tlama nitrogen (Mohlala. B E lumelloa ho feta boleng bo boletsoeng, ha feela litaba tsa n li eketseha ka 0.001%, litaba tse phahameng tsa p e fokotseha ka 0.005% ka nako e le 'ngoe. Litaba tsa n ka tlhatlhobo ea ho qhibilihileng ha lia lokela ho feta 0.012%. C Haeba sebopeho sa lik'hemik'hale se bonts'a litaba tse ngata tsa aluminium ea 0.020% le karo-palo e 'ngoe ea li-nitrojene e lekaneng ha e sebetse. Lintho tse tlamang tsa Nitrogen tse tlatsitsoeng li tla hlokomeloa litokomaneng tsa tlhahlobo.

| |||||||||

| Keletso | Boikokobetso bo tlase | matla a tšepe | Nako e nyane ea nako | Matla a Bonyane | |||||||||||||

| Lebitso la Steel | Nomoro ea tšepe | Bophahamo bo tloaelehileng | Bophahamo bo tloaelehileng | Bophahamo bo tloaelehileng | Bophahamo bo tloaelehileng | ||||||||||||

| ≤16 | > 16 | > 40 | > 63 | > 80 | > 100 | ≤3 | > 3 | > 100 | ≤40 | > 40≤63 | > 63≤100 | > 100≤120 | -20 ℃ | 0 ℃ | 20 ℃ | ||

| ≤ 40 | ≤ 63 | ≤ 80 | ≤ 100 | ≤ 120 | ≤100 | ≤ 120 | |||||||||||

| S235JRH | 1.0039 | 235 | 225 | 215 | 215 | 215 | 195 | 360-510 | 360-510 | 360-500 | 26 | 25 | 24 | 22 | - | - | 27 |

| S275j0hc | 1.0149 | 275 | 265 | 255 | 245 | 235 | 225 | 430-5880 | 410-560 | 400-540 | 23 | 22 | 21 | 19 | - | 27 | - |

| S2755J2h | 1.0138 | 27 | - | - | |||||||||||||

| S355j0hc | 1.0547 | 355 | 345 | 355 | 325 | 315 | 295 | 510-680 | 470-6330 | 450-600 | 22 | 21 | 20 | 18 | - | 27 | - |

| S355J2h | 1.0576 | 27 | - | - | |||||||||||||

| S355k2h | 1.051212 | 40 | - | - | |||||||||||||

| boleng bo bolelele sa sampole. Boleng bo tloaelehileng ba mofuta o feteletseng bo tlase ho 2% bo tlase ho boleng ba "3mm" feela ha khetho e lekana | |||||||||||||||||

Teko ea Harness, liteko tsa tsitsipano, liteko tse sa sebetseng, ho hloekisoa hoa tšepe

Mekhoa ea Phepelo: Linense tse 2000 ka khoeli ka sehlopha sa Gsel102210-1-2006 Steel Pipe

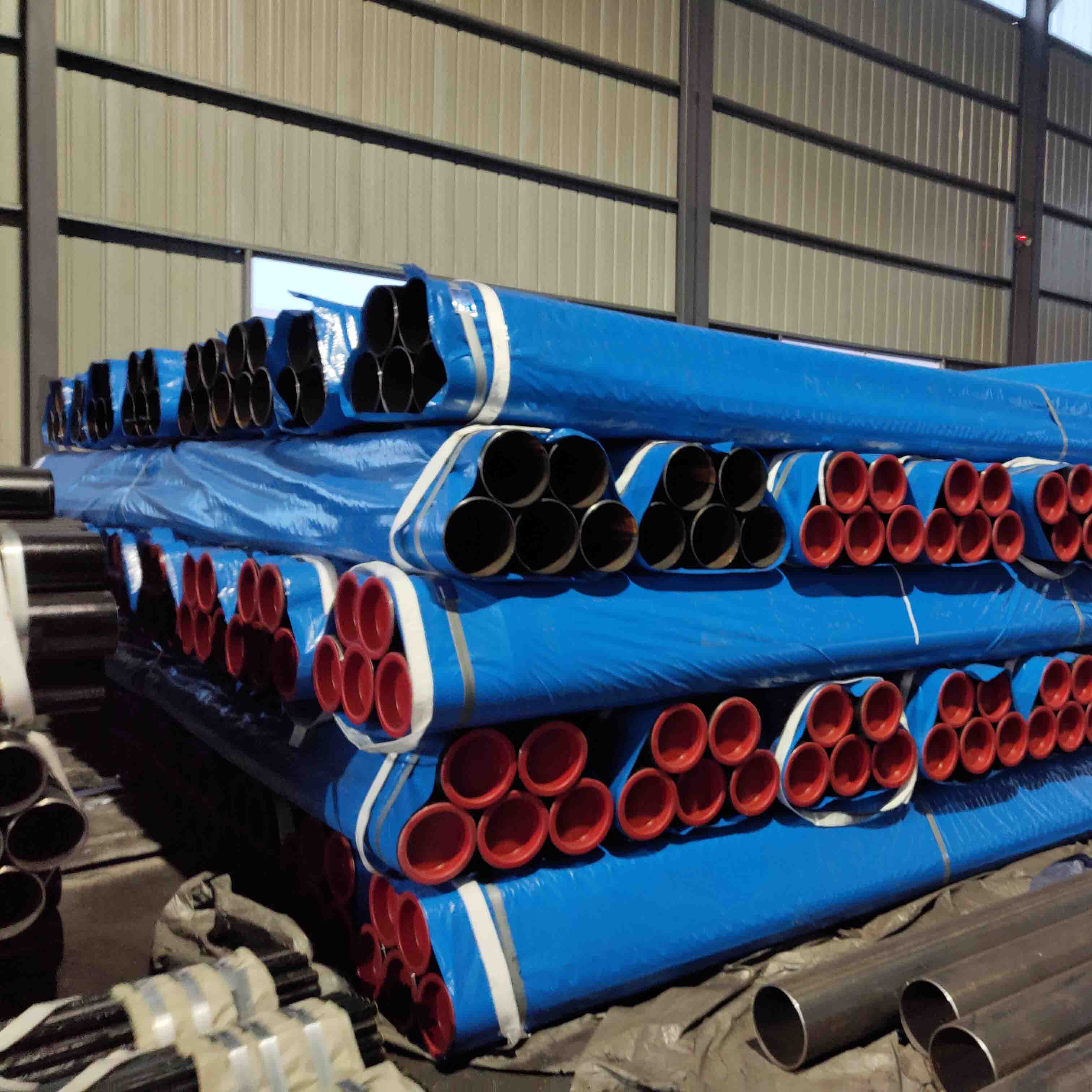

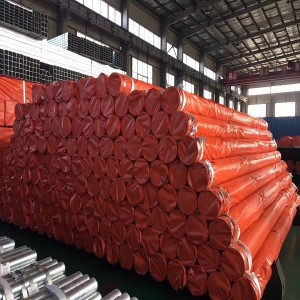

Ka bongata le ka lebokoseng le matla la lehong

Matsatsi a 7-14 haeba a le setoko, matsatsi a 30-45 a ho hlahisa

30% Desenit, 70% L / C kapa B / L COP kapa 100% L / C