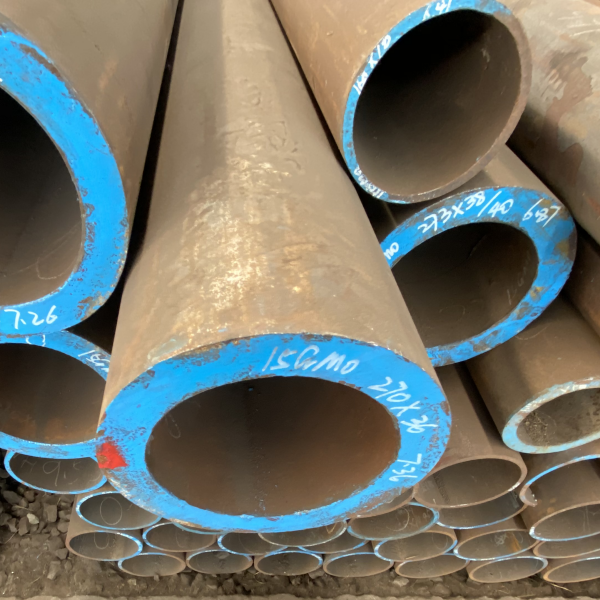

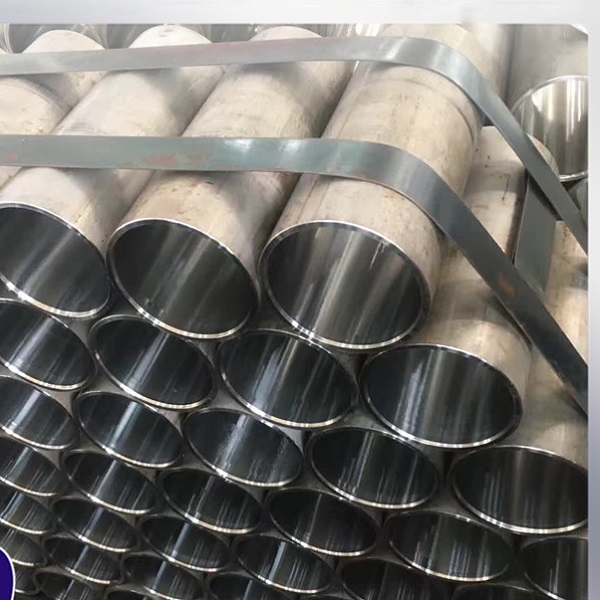

Li-Tubis tsa leoatleng bakeng sa peteroleum o hlasimollang, GB9948-2006, Sanon Pipe

| Tloaelo:GB9948-2006 | Phekolo ea mocheso: ho kopanya / ho fetolela / ho futhumatsa |

| Sehlopha sa sehlopha sa Ke: 10111CRME ,,5Mi, 07CRME9N0, jj | Bophara ba kantle (ho potoloha): 10 - 1000 mm |

| Botenya: 1 - 100 mm | Kopo: Litlhaloso tsa mocheso li chesa |

| Bophara ba kantle (ho potoloha): 10 - 1000 mm | Phekolo ea holimo: E le tlhokahalo ea bareki |

| Bolelele: Bolelele ba bolelele kapa bolelele bo sa sebetseng | Mokhoa: ho chesa |

| Sebopeho sa karolo: ho potoloha | Pipe e khethehileng: Popi e teteaneng |

| Sebaka sa Tšimoloho: China | Ts'ebeliso: Litlhaloso tsa mocheso |

| Setifikeiti: Iso9001: 2008 | Teko: Ut / MT |

Li-Tubis tsa leoatleng bakeng sa lits'ila tsa peterole li sebetsa ho li-tubes tse se nang meeli bakeng sa li-tubess tsa sebnace, li-decupes ea mocheso indastering ea petrochemical.

Litoro tsa sebopeho sa Carbon tsa boemo ba li-steel tsa tšepe li na le 20g, 20mng le 25mng.

Li-sweel tsa Alloy Stered: 15mog, 20mog, ea 12crmog

15CRCRMOG, 12R2MOMMOME, 12CRMVGG, joalo-joalo

Mophato oa sebopeho sa boleng bo holimo sa carbon: 10 #,20 #

Maqhubu a boemo bo holimo a carbon sebopeho sa tšepe: 20g, 20mng le 25mng

Li-grade tsa li-sweel tsa alloy: 15mog, 20mog, ea 12crmog,

| No | Keletso | Karolo ea lik'hemik'hale%% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Sehlekehleke sa boleng bo holimo sa Carbon | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0,15 | <0,15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0,15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Alloy steel | 12CRMO | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CRMO | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1,11 | 0. 40-0.55 | <0. 30 | - | - | 一 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12crlmo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12crmmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12r2mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1,13 | <0. 30 | - | - | 一 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12cr5Moi | <0,15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12cr5Mont | |||||||||||||

| 12rzmoi | <0,15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1,1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12cr9mont | |||||||||||||

| Tšepe e sa sebetseng ea mocheso ea mocheso | 07CRL9nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 0731n8nillnb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07CRl9nillti | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4c-0. 60 | 一 一 | 一 一 | 0.03 | 0. 015 | |

| 022CRL7nil2MOMO2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 一 | 一 一 | - | 0.03 | 0. 015 | |

| Che | Tense Mpa | Khefutsa Mpa | Elong ka mor'a ho robeha A /% | Shork Invoorp Energna Kv2 / J | Nomoro ea thata ea brinell | ||

| Portrait | Transver | Portrait | Transver | ||||

| eseng ka tlase ho | eseng ho feta | ||||||

| 10 | 335 ~475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410 ~550 | 245 | 24 | 22 | 40 | 27 | |

| 12CRMO | 410 ~560 | 205 | 21 | 19 | 40 | 27 | 156 hbw |

| 15CRMO | 440 ~640 | 295 | 21 | 19 | 40 | 27 | 170 hbw |

| 12crlmo | 415 ~560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12crmmov | 470 ~640 | 255 | 21 | 19 | 40 | 27 | 179 hbw |

| 12r2mo | 450 ~ 600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12cr5Moi | 415 ~590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12cr5Mont | 480 ~640 | 280 | 20 | 18 | 40 | 27 | - |

| 12rzmoi | 460 ~640 | 210 | 20 | 18 | 40 | 27 | 179 hbw |

| 12cr9mont | 590-7740 | 390 | 18 | 16 | 40 | 27 | |

| O7ctor9nilo | 2520 | 205 | 35 | 187 hbw | |||

| 0731n8nillnb | > 520 | 205 | 35 | - | 187 hbw | ||

| 07CRl9nillti | > 520 | 205 | 35 | - | - | 187 hbw | |

| 022CRL7nil2MOMO2 | > 485 | 170 | 35 | 一 一 | - | 187 hbw | |

| Bakeng sa tšepe e nang le mafika a mafike e ka tlase ho 5mm tube ha e etse boima ba liteko | |||||||

Teko ea Hydraulic

Teko ea Hydraulic e tla etsoa bakeng sa tšepe ea tšepe. Khatello e phahameng ea liteko ke 20 MPA. Tlas'a khatello ea liteko, nako ea ho tsitsa e ke ke ea hlola e feta 10 s, 'me ho lutla ha phala ha hoa lumelloa.

Teko e bataletseng

Teko e batang e tla etsoa bakeng sa pompo ea tšepe e nang le bophara ba ka ntle e kholo ho feta 22 mm

Teko e Ntle

Mera e phahameng ea carbo ea boleng bo holimo ea carbon e se nang letsoai e nang le bophara ba tšepe e nang le bophara ba tšepe e se nang bophara ba 76 mm le matale a ho eketsa tlhahlobo. Teko e ntle e tla etsoa ka mocheso oa kamore. Sekhahla sa kantle sa motho ea ka ntle sa mohlala ka mor'a ho tabolla ka holimo ho 60% Ho ea ka litlhoko tsa ba lekang 'me ba tseba konteraka, tšepe ea aloy ea sebopeho e ka sebelisoa bakeng sa tlhahlobo e kholo.

Teete ea ho se na letho

Liphara tsa tšepe li tla ba tlasa Flaw ea Ultrasonic e bonts'a e le 'ngoe ho latela lipehelo tsa GB / t 577-2008. Ho latela litlhoko tsa bafosi, liteko tse ling tse seng tsa kotsi li ka eketsoa kamora puisano lipakeng tsa morekisi le chelete ebile li bonts'itsoe konteraka.

Teko ea boithuto

Tlhahlobo ea ts'ireletso ea moea o mongata o tla etsoa bakeng sa ho hlonama (ho senya ho futhumatsa mocheso. Mokhoa oa tlhahlobo o tla ba teng ho latela lipehelo tsa Wonder ea Chinese E ka GB / T 4334-2008, le tloaelo ea methapo e sa sebetsoeng.

Kamora puisano lipakeng tsa mofani oa thepa le mofosi, 'me e tsebahalang konterakeng, moahloli o ka etsa mekhoa ea liteko tse ling tsa tlhahiso.

Oli, petrogchemical, khatello ea maikutlo, khatello e phahameng ea boiketsetso

Karolo ea lik'hemik'hale

| Brand | Karolo ea lik'hemik'hale (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| 15CRMO | 0.12 ~ 0 0,18 | 0.40 ~ 0.70 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Thepa ea mochini

| Brand | Tense Mpa | Khefutsa Mpa | Ellation (%) |

| 15CRMO | 440 ~ 640 | 295 | 22 |