Izinto zombhobho wentsimbi engenasithungo: Umbhobho wentsimbi ongenamthungo wenziwe nge-bielt okanye i-bibe ye-tube ye-tube ye-tube ye-tube ye-rube, kwaye emva koko ishushu, ibandayo okanye ukubanda kakhulu okanye ukubanda kakhulu okanye ukubanda ikhutshiwe. Izinto ezenziweyo ngokubanzi zenziwe ngentsimbi ephezulu yekhabhoni efana ne-10,20, 30, 35,45, intsimbi yesakhiwo esezantsi yesakhiwo esifana16mn, I-5MNV okanye intsimbi ye-alcy efana ne-9crr, i-30crmledi, i-45mn2, i-40mnb ngokuqengqa eshushu okanye iqengqele. Imibhobho ye-wamp yenoko yentsimbi ye-carbon yentsimbi efana ne-10 ne-20 isetyenziselwa ikakhulu kwimibhobho yokuhanjiswa kweenqanawa.

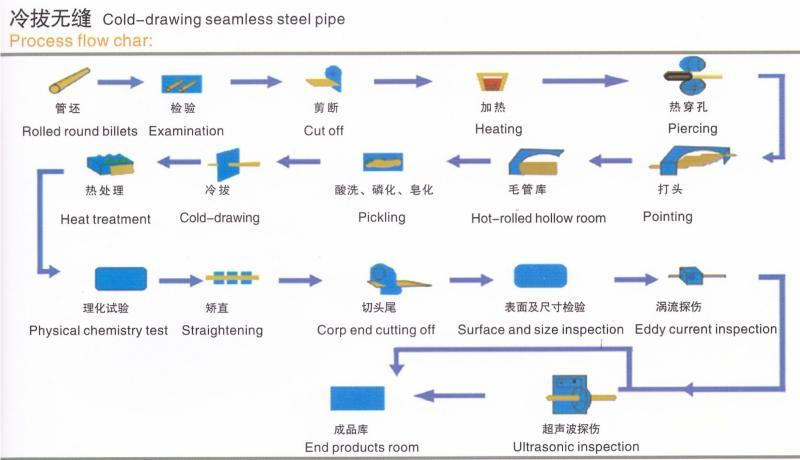

Ngokwesiqhelo, inkqubo yemveliso yemibhobho yentsimbi engenamthungo yahlulwe yangamacala amabini: inkqubo yokubanda yokuzoba kunye nenkqubo eshushu eshukumayo. Oku kulandelayo sisishwankathelo senkqubo yokuhamba kwemibhobho yentsimbi ebandayo yentsimbi kunye nemibhobho yentsimbi eqingqiweyo yethumba:

I-Tool yentsimbi yentsimbi yentsimbi: I-Tube Billet Gillet Hible Teat → i-tube iqengqelekayo)

Ii-piles eziqengqelekayo eziqengqelekayo ezingenamthungo ezigutyungelweyo zingena bhambile kufuneka kuqala zithathwe uqengqele, kwaye iimvavanyo zeSikes kufuneka zenziwe emva kokupheliswa. Ukuba akukho mpendulo iqhekeza kumphezulu, ityhubhu ejikelezileyo kufuneka inqunyulwe ngumatshini wokusika kwaye usike kwii-billets ngobude bemitha enye. Emva koko faka inkqubo yokuthiyisha. I-ANNALTE kufuneka ikhutshwe ngolwelo lwe-acidic. Ngexesha lokuthathwa, nikela ingqalelo ukuba kukho inani elikhulu leebhubhu ngaphezulu komphezulu. Ukuba kukho inani elikhulu leebhubhu, oko kuthetha ukuba umgangatho wombhobho wentsimbi awuhlangabezana nemigangatho ehambelana nayo.

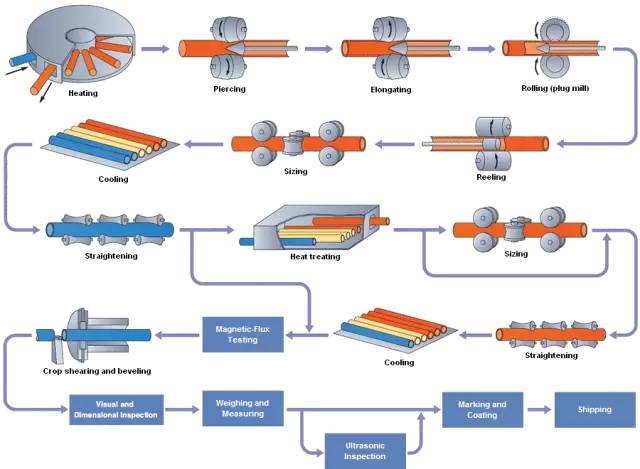

I-Hot-ishushu (ikhutshiwe) yentsimbi yentsimbi yentsimbi: i-tube ye-tube ye-tube → Ukufudumeza

Ukuntywila okushushu, njengoko igama lithetha, linobushushu obuphakathi kwisiqwengana esiqengqelekayo, ke ukunyangwa okungapheliyo kuncinci kwaye isixa esikhulu sengxaki sinokufezekiswa. Imeko yokuhanjiswa kweempuku ezinomthungo eshushu eshushu eshushu kakhulu ishushu kakhulu kwaye ityhutyha ubushushu ngaphambi kokuhanjiswa. Ityhubhu eqinileyo ihlolwe kwaye isiphene somphezulu sisusiwe, sinqunywe kubude obufunekayo, sigxile kwisiphelo sokuphela kwetyhubhu, emva koko bathunyelwe kwizilonda zokufudumeza kwaye bathwaxwa kwi-pube. Ngelixa ijikeleza kwaye iqhubela phambili ngokuqhubekayo. Phantsi kwesenzo seengqengqele kunye nentloko, i-cavity ngokuthe ngcembe i-tube, ebizwa ngokuba yityhubhu ebi. Emva kokuba ityhubhu isuswe, ithunyelwe kumatshini oqengqelekayo ozenzekelayo wokuqengqesha, kwaye ke ubukhulu bomhlaba buhlengahlengiswa ngumatshini wokulinganisa, kwaye ububanzi bumiselwe ngumatshini wokulinganisa. Emva konyango olushushu olujikelezayo, uvavanyo lokuphakama kufuneka lwenziwe. Ukuba idayiti eliphangaleleyo likhulu kakhulu, kufuneka liqwalaselwe kwaye lilungiswe, kwaye ekugqibeleni libhalwe kwaye lijonge kugcino.

Ukuthelekisa inkqubo yokuzoba ebandayo kunye nenkqubo eshushu eqengqelekayo: Inkqubo eqengqelekayo ebandayo kunenkqubo eshushu, kodwa umgangatho womhlaba, inkangeleko yentsimbi eqengqelekayo ilunge ngakumbi kunezona zincinci zinokuthambeka.

Ubungakanani: Ubungakanani bangaphandle bepayiphu eshushu eshushu kakhulu buyinto enkulu kuno-32mm, kwaye ubukhulu bodonga yi-2,5-200mm. Ububanzi bangaphandle be-pipe egcwele intsimbi ebandayo bunokuba yi-6mm, ubukhulu becala bungaphezulu kwe-0.25mm, ububanzi be-pied, kunye nokuchaneka kwe-0.25mm (kunye nokuchaneka kwe-Doll), kunye nokuchaneka kwe-Wall.

Inkangeleko: Nangona ububanzi be-wall egcwele i-seam egutyungelayo buqhekeka kunoko umbhobho wentsimbi evuthiweyo eshushu, umphezulu obonakala emngxunyeni oshushu wentsimbi, umphezulu ongena rhabaxa, kwaye ububanzi bungabi mbi kakhulu.

Imeko yokuhambisa: Imibhobho yentsimbi eqingqiweyo ihanjiswa kwi-rhulumente eshushu okanye ityhubhu eshushu, kwaye imibhobho yentsimbi ebandayo ihanjiswa kwiLizwe eliphantsi lobushushu.

IXESHA LOKUQALA: AUG-21 ukuya ku-2124