[Daakọ] 12CrMoVG Paipu irin Alailẹgbẹ fun awọn igbomikana titẹ-giga ni GB/T5310-2017 Standard

Akopọ

Standard: GB/T5310-2017

Ẹgbẹ Ite: 20G, 20MnG, 25MnG, ati bẹbẹ lọ

Sisanra: 1 - 100 mm

Ode opin (Yika): 10 - 1200 mm

Ipari: Gigun ti o wa titi tabi ipari laileto (6-12m)

Apẹrẹ Abala: Yika

Ibi ti Oti: China

Iwe eri: ISO9001:2008

Alloy Tabi Ko: Alloy

Ohun elo: igbomikana Pipe

Itọju Ilẹ: Bi ibeere alabara

Ilana: Hot Rolled

Itọju igbona: Annealing / normalizing

Pataki Pipe: igbomikana Pipe

Lilo: igbomikana ati Heat Exchanger

Idanwo: ECT/UT/Hydrau Static

Ohun elo

O ti wa ni o kun lo lati ṣe ga-didara erogba igbekale irin, alloy igbekale, irin ati ki o alagbara ooru-sooro, irin seamless, irin pipes fun ga titẹ ati loke nya igbomikana pipes.

Ti a lo ni akọkọ fun titẹ giga ati iṣẹ iwọn otutu giga ti igbomikana (Tube Superheater, tube reheater, tube itọsọna afẹfẹ, tube nya si akọkọ fun awọn igbomikana giga giga ati olekenka). Labẹ iṣẹ ti gaasi flue otutu giga ati oru omi, tube yoo oxidize ati baje. O nilo pe paipu irin ni agbara giga, resistance giga si ifoyina ati ipata, ati iduroṣinṣin igbekalẹ to dara.

Akọkọ ite

Ite ti ga-didara erogba igbekale irin: 20g,20mng,25mng

Ite ti alloy igbekale irin: 15mog,20mog,12crmog,15crmog,12cr2mog,12crmovg,12cr3movsitib, ati be be lo

Ite ti ipata-sooro ooru, irin: 1cr18ni9 1cr18ni11nb

Ohun elo Kemikali

| Ipele | Didara Kilasi | Ohun-ini Kemikali | ||||||||||||||

| C | Si | Mn | P | S | Nb | V | Ti | Cr | Ni | Cu | Nd | Mo | B | Als" | ||

| ko ju | ko kere ju | |||||||||||||||

| Q345 | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.30 | 0.50 | 0.20 | 0.012 | 0.10 | - | - | |||

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0.07 | 0.15 | 0.20 | 0.015 | ||||||||||

| D | 0.18 | 0.030 | 0.025 | |||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q390 | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.07 | 0.20 | 0.20 | 0.3. | 0.50 | 0.20 | 0.015 | 0.10 | - | - |

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0.015 | |||||||||||||

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q420 | A | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 0.07 | 0.2. | 0.20 | 0.30 | 0.80 | 0.20 | 0.015 | 0.20 | - | - |

| B | 0.035 | 0.035 | ||||||||||||||

| C | 0.030 | 0.030 | 0.015 | |||||||||||||

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q460 | C | 0.20 | 0.60 | 1.80 | 0.030 | 0.030 | 0.11 | 0.20 | 0.20 | 0.30 | 0.80 | 0.20 | 0.015 | 0.20 | 0.005 | 0.015 |

| D | 0.030 | 0.025 | ||||||||||||||

| E | 0.025 | 0.020 | ||||||||||||||

| Q500 | C | 0.18 | 0.60 | 1.80 | 0.025 | 0.020 | 0.11 | 0.20 | 0.20 | 0.60 | 0.80 | 0.20 | 0.015 | 0.20 | 0.005 | 0.015 |

| D | 0.025 | 0.015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Q550 | C | 0.18 | 0.60 | 2.00 | 0.025 | 0,020 | 0.11 | 0.20 | 0.20 | 0.80 | 0.80 | 0.20 | 0.015 | 0.30 | 0.005 | 0.015 |

| D | 0.025 | 0,015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Q620 | C | 0.18 | 0.60 | 2.00 | 0.025 | 0.020 | 0.11 | 0.20 | 0.20 | 1.00 | 0.80 | 0.20 | 0.015 | 0.30 | 0.005 | 0.015 |

| D | 0.025 | 0.015 | ||||||||||||||

| E | 0.020 | 0.010 | ||||||||||||||

| Ayafi fun awọn onipò Q345A ati Q345B, irin yẹ ki o ni o kere ju ọkan ninu awọn eroja ọkà Al, Nb, V, ati Ti. Gẹgẹbi awọn iwulo, olupese le ṣafikun ọkan tabi diẹ ẹ sii awọn eroja ọkà ti a ti tunṣe, iye ti o pọju yẹ ki o pade awọn ibeere ni tabili. Nigbati a ba dapọ, Nb + V + Ti <0.22% °Fun Q345, Q390, Q420 ati Q46O grades, Mo + Cr <0.30% oNigbati a ba lo ipele Cr ati Ni kọọkan gẹgẹbi eroja iyokù, akoonu Cr ati Ni ko yẹ jẹ diẹ sii ju 0.30%; nigba ti o nilo lati fi kun, akoonu rẹ yẹ ki o pade awọn ibeere ti o wa ninu tabili tabi ṣe ipinnu nipasẹ olupese ati ẹniti o ra nipasẹ ijumọsọrọ.J Ti olupese ba le ṣe idaniloju pe akoonu nitrogen pade awọn ibeere ti o wa ninu tabili, iṣeduro akoonu nitrogen le ko ṣee ṣe. Ti Al, Nb, V, Ti ati awọn eroja alloy miiran pẹlu imuduro nitrogen ti wa ni afikun si irin, akoonu nitrogen ko ni opin. Akoonu imuduro nitrogen yẹ ki o wa ni pato ninu ijẹrisi didara.'Nigbati o ba nlo gbogbo aluminiomu, akoonu aluminiomu lapapọ AIt ^ 0.020% B | ||||||||||||||||

Mechanical Ini

| No | Ipele | Mechanical Ini | ||||

|

|

| Fifẹ | So eso | Tesiwaju | Àkóbá (J) | Ọwọ |

| 1 | 20G | 410- | ≥ | 24/22% | 40/27 | - |

| 2 | 20MnG | 415- | ≥ | 22/20% | 40/27 | - |

| 3 | 25MnG | 485- | ≥ | 20/18% | 40/27 | - |

| 4 | 15MoG | 450- | ≥ | 22/20% | 40/27 | - |

| 6 | 12CrMoG | 410- | ≥ | 21/19% | 40/27 | - |

| 7 | 15CrMoG | 440- | ≥ | 21/19% | 40/27 | - |

| 8 | 12Cr2MoG | 450- | ≥ | 22/20% | 40/27 | - |

| 9 | 12Cr1MoVG | 470- | ≥ | 21/19% | 40/27 | - |

| 10 | 12Cr2MoWVTiB | 540- | ≥ | 18/-% | 40/- | - |

| 11 | 10Cr9Mo1VNbN | ≥ | ≥ | 20/16% | 40/27 | ≤ |

| 12 | 10Cr9MoW2VNbBN | ≥ | ≥ | 20/16% | 40/27 | ≤ |

Ifarada

Sisanra Odi ati Iwọn Ita:

Ti ko ba si awọn ibeere pataki, paipu yoo jẹ ifijiṣẹ bi iwọn ila opin ode deede ati sisanra odi deede. Bi atẹle dì

| Iyasọtọ iyasọtọ | Ọna ti iṣelọpọ | Iwọn paipu | Ifarada | |||

| Ipele deede | Ipele giga | |||||

| WH | Hot Rolled (extrude) paipu | Deede lode Opin (D) | <57 | Oṣuwọn 0.40 | ± 0,30 | |

| 57 〜325 | SW35 | ±0.75%D | ± 0.5% D | |||

| S>35 | ±1% D | ±0.75%D | ||||

| > 325-6. | + 1%D tabi + 5.Mu ọkan ti o kere 一2 | |||||

| > 600 | + 1%D tabi + 7,Mu ọkan ti o kere 一2 | |||||

| Deede Odi Sisanra (S) | <4.0 | ±|・丨) | ±0.35 | |||

| > 4.0-20 | + 12.5% S | ± 10% S | ||||

| >20 | DV219 | ± 10% S | ± 7.5% S | |||

| 219 | + 12.5% S -10% S | 土10% S | ||||

| WH | Gbona imugboroosi paipu | Deede lode Opin (D) | gbogbo | ±1% D | ± 0.75%. |

| Deede Odi Sisanra (S) | gbogbo | + 20% S -10% S | + 15% S -io%s | ||

| WC | Tutu yiya (yiyi) Ppipe | Deede lode Opin (D) | <25.4 | ±'L1j | - |

| >25.4 〜4() | ±0.20 | ||||

| >40 “50 | |: 0.25 | - | |||

| > 50 〜60 | ±0.30 | ||||

| > 60 | ± 0.5% D | ||||

| Deede Odi Sisanra (S) | <3.0 | ±0.3 | ±0.2 | ||

| > 3.0 | S | ± 7.5% S |

Gigun:

Awọn ibùgbé ipari ti irin pipes jẹ 4 000 mm ~ 12 000 mm. Lẹhin ijumọsọrọ laarin awọn olupese ati awọn eniti o, ati ki o fọwọsi ni awọn guide, o le wa ni jišẹ irin oniho pẹlu kan ipari ti o tobi ju 12 000 mm tabi kuru ju I 000 mm sugbon ko kuru ju 3 000 mm; gigun kukuru Nọmba awọn paipu irin ti o kere ju 4,000 mm ṣugbọn ko kere ju 3,000 mm ko ni kọja 5% ti apapọ nọmba awọn paipu irin ti a firanṣẹ

Iwọn ifijiṣẹ:

Nigbati paipu irin ti wa ni jiṣẹ ni ibamu si iwọn ila opin ti ita ati sisanra odi ipin tabi iwọn ila opin ti inu ati sisanra odi ipin, paipu irin ti wa ni jiṣẹ ni ibamu si iwuwo gangan. O le tun ti wa ni jišẹ ni ibamu si awọn tumq si àdánù.

Nigbati paipu irin ti wa ni jiṣẹ ni ibamu si iwọn ila opin ti ita ati sisanra ogiri ti o kere ju, paipu irin ti wa ni jiṣẹ ni ibamu si iwuwo gangan; ipese ati eletan ẹni duna. Ati pe o tọka si ninu adehun naa. Paipu irin naa tun le jiṣẹ ni ibamu si iwuwo imọ-jinlẹ.

Ifarada iwuwo:

Gẹgẹbi awọn ibeere ti olura, lẹhin ijumọsọrọ laarin olupese ati olura, ati ninu adehun, iyapa laarin iwuwo gangan ati iwuwo imọ-jinlẹ ti paipu irin ifijiṣẹ yoo pade awọn ibeere wọnyi:

a) Paipu irin kan: ± 10%;

b) Ipele kọọkan ti awọn paipu irin pẹlu iwọn to kere ju ti 10 t: ± 7.5%.

Ibeere idanwo

Idanwo Hydraustatic:

Paipu irin yẹ ki o ṣe idanwo hydraulically ọkan nipasẹ ọkan. Iwọn titẹ idanwo ti o pọju jẹ 20 MPa. Labẹ titẹ idanwo, akoko imuduro yẹ ki o ko kere ju 10 s, ati paipu irin ko yẹ ki o jo.

Lẹhin ti olumulo gba, idanwo hydraulic le rọpo nipasẹ idanwo eddy lọwọlọwọ tabi idanwo jijo oofa oofa.

Idanwo ti ko ni iparun:

Awọn paipu ti o nilo ayẹwo diẹ sii yẹ ki o ṣe ayẹwo ultrasonically ọkan nipasẹ ọkan. Lẹhin idunadura naa nilo igbanilaaye ti ẹgbẹ ati pe o wa ni pato ninu adehun, awọn idanwo miiran ti kii ṣe iparun le ṣafikun.

Idanwo fifẹ:

Awọn tubes pẹlu iwọn ila opin ti ita ti o tobi ju 22 mm yoo wa labẹ idanwo fifẹ. Ko si delamination ti o han, awọn aaye funfun, tabi awọn aimọ yẹ ki o waye lakoko gbogbo idanwo naa.

Idanwo igbona:

Gẹgẹbi awọn ibeere ti olura ati ti a sọ ninu adehun, paipu irin pẹlu iwọn ila opin ≤76mm ati sisanra ogiri ≤8mm le ṣee ṣe idanwo flaring. Idanwo naa ni a ṣe ni iwọn otutu yara pẹlu taper ti 60 °. Lẹhin gbigbọn, oṣuwọn gbigbọn ti iwọn ila opin ode yẹ ki o pade awọn ibeere ti tabili atẹle, ati pe ohun elo idanwo ko gbọdọ fi awọn dojuijako tabi rips han.

| Irin Iru

| Oṣuwọn didan iwọn ila opin ita ti paipu irin/% | ||

| Inu Opin/Ode opin | |||

| <0.6 | >0.6 〜0.8 | > 0.8 | |

| Ga-didara erogba igbekale irin | 10 | 12 | 17 |

| Irin alloy igbekale | 8 | 10 | 15 |

| • Iwọn ila opin ti inu jẹ iṣiro fun apẹẹrẹ. | |||

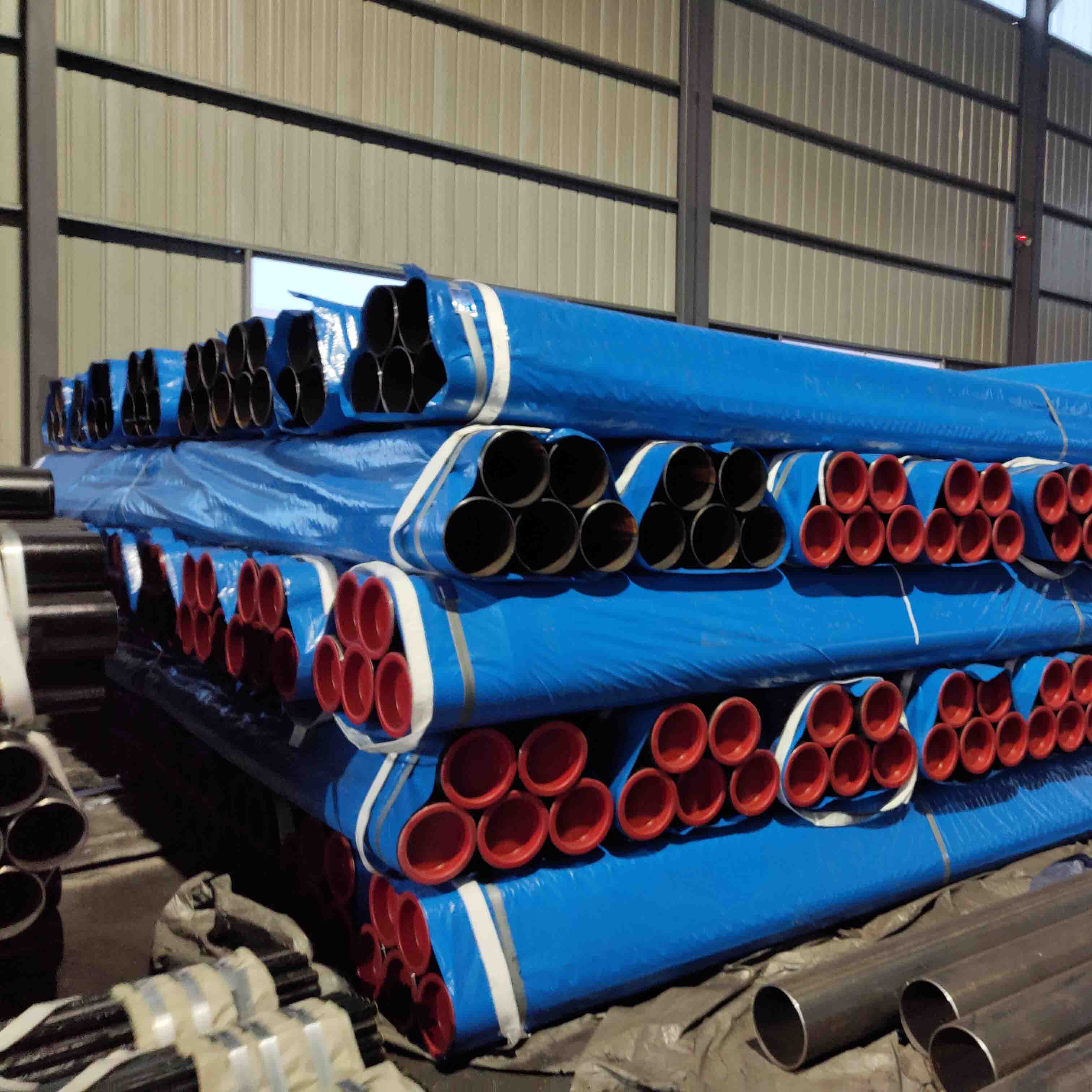

![[Daakọ] 12CrMoVG Paipu irin Alailẹgbẹ fun awọn igbomikana titẹ-giga ni GB/T5310-2017 Aworan Ifihan Standard](http://www.sanonpipe.com/uploads/8d9d4c2f9.jpg)

![[Daakọ] 12CrMoVG Paipu irin Alailẹgbẹ fun awọn igbomikana titẹ-giga ni GB/T5310-2017 Standard](http://www.sanonpipe.com/uploads/8d9d4c2f9-300x296.jpg)

![[Daakọ] 12CrMoVG Paipu irin Alailẹgbẹ fun awọn igbomikana titẹ-giga ni GB/T5310-2017 Standard](http://www.sanonpipe.com/uploads/7ace83c11-300x300.jpg)

![[Daakọ] 12CrMoVG Paipu irin Alailẹgbẹ fun awọn igbomikana titẹ-giga ni GB/T5310-2017 Standard](http://www.sanonpipe.com/uploads/93ed80c6-289x300.png)