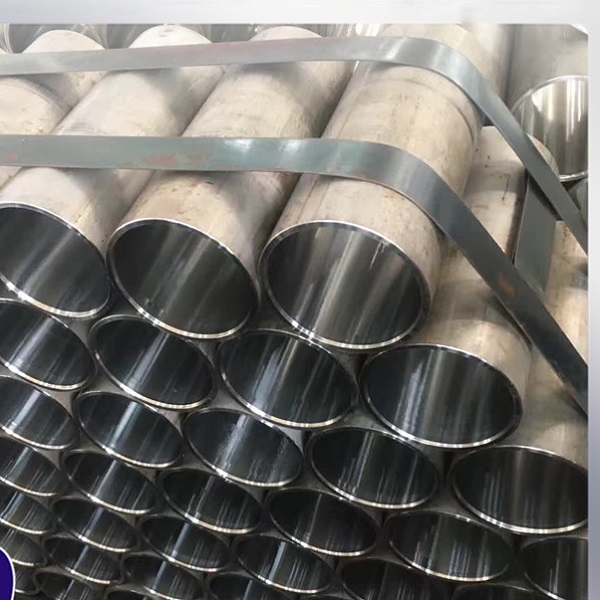

Irin igbekalẹ erogba ti o ga julọ, irin igbekalẹ alloy ati irin alagbara, irin alagbara, irin pipe ti ko ni itutu pipe fun awọn paipu igbomikana nya si labẹ titẹ giga ati titẹ loke

Akopọ

Standard: GB9948-2006

Ẹgbẹ ipele: 10,12CrMo,15CrMo, 07Crl9Nil0, ati bẹbẹ lọ

Sisanra: 1 - 100 mm

Ode opin (Yika): 10 - 1000 mm

Ipari: Gigun ti o wa titi tabi ipari laileto

Apẹrẹ Abala: Yika

Ibi ti Oti: China

Iwe eri: ISO9001:2008

Itọju Ooru: Annealing/normalizing/Tempering

Iwọn Ode (Yika): 10 - 1000 mm

Ohun elo: awọn tubes paṣipaarọ ooru

Itọju Ilẹ: Bi Ibeere Onibara

Ilana: Hot Rolled

Paipu Pataki: Nipọn Wall Pipe

Lilo: ooru paṣipaarọ tubes

Idanwo:UT/MT

Ohun elo

Awọn tubes irin ti ko ni idọti fun fifọ epo epo jẹ iwulo si awọn tubes irin ti ko ni idọti fun awọn tubes ileru, awọn tubes paṣipaarọ ooru ati awọn paipu titẹ ni ile-iṣẹ petrochemical.

Awọn ipele irin igbekalẹ erogba to gaju jẹ 20g, 20mng ati 25mng.

Awọn onipò irin igbekalẹ alloy: 15mog, 20mog, 12 crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, ati bẹbẹ lọ

Akọkọ ite

Iwọn ti irin igbekalẹ erogba didara ga: 10#,20#

Awọn ipele irin igbekale erogba to gaju: 20g, 20mng ati 25mng

Alloy igbekale irin onipò: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, ati be be lo

Ohun elo Kemikali

| No | Ipele | Ohun elo Kemikali% | ||||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | |||

| ≤ | ||||||||||||||

| Ga didara erogba igbekale irin | 10 | 0. 07-0.13 | 0.17-0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0.015 | |

| 20 | 0.17-0. 23 | 0.17-0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0.015 | ||

| Alloy igbekale irin | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 | |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 | ||

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0.025 | 0.015 | ||

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15-0. 30 | <0. 20 | 0.025 | 0.010 | ||

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 | ||

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45-0. 60 | <0. 60 | - | - | <0. 20 | 0.025 | 0.015 | |||

| 12Cr5MoNT | ||||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0.025 | 0, 015 | ||

| 12Cr9MoNT | ||||||||||||||

| Irin alagbara ooru sooro | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0.030 | 0.015 | |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0.030 | 0.015 | ||

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0.015 | ||

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0.015 | ||

Mechanical Ini

| Rara | Fifẹ MPa | So eso MPa | Elong lẹhin fifọ A/% | Agbara gbigba Shork kv2/j | Brinell líle nọmba | ||

| aworan | transver | aworan | transver | ||||

| ko kere ju | ko si ju | ||||||

| 10 | 335 “475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410-550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410 “560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440 “640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415 -560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470 “640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415-590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoNT | 480 “640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460 ~ 640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MoNT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | > 520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | > 520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | > 485 | 170 | 35 | 一 | - | 187 HBW | |

| Fun irin pẹlu sisanra ogiri kere ju tube 5mm maṣe ṣe idanwo lile | |||||||

Ibeere idanwo

Idanwo hydraulic

Idanwo hydraulic yoo ṣee ṣe fun awọn paipu irin ni ọkọọkan. Iwọn titẹ idanwo ti o pọju jẹ 20 MPa. Labẹ titẹ idanwo, akoko imuduro ko ni kere ju 10 s, ati jijo ti paipu irin ko gba laaye.

Idanwo fifẹ

Idanwo fifẹ yẹ ki o ṣe fun paipu irin pẹlu iwọn ila opin ti ita ti o tobi ju 22 mm

Idanwo igbona

Irin igbekalẹ erogba to gaju ati irin alagbara (sooro-ooru) awọn paipu irin pẹlu iwọn ila opin ti ita ti ko ju 76 mm ati sisanra ogiri ti ko ju 8 mm lọ yoo jẹ koko-ọrọ si idanwo faagun. Idanwo flaring yẹ ki o ṣee ṣe ni iwọn otutu yara. Oṣuwọn itọsi ti ita ti ita ti apẹrẹ lẹhin ti o wa ni oke mojuto taper jẹ 60% ti gbigbọn yoo pade awọn ibeere ti tabili 7. Ko si awọn dojuijako tabi awọn dojuijako ti a gba laaye lori apẹẹrẹ lẹhin gbigbọn. Gẹgẹbi awọn ibeere ti olubẹwẹ ati akiyesi ninu adehun naa, irin igbekalẹ alloy tun le ṣee lo fun idanwo faagun.

Teste ti ko ni iparun

Awọn paipu irin yoo jẹ koko-ọrọ si wiwa abawọn ultrasonic ọkan nipasẹ ọkan ni ibamu pẹlu awọn ipese ti GB / T 5777-2008. Gẹgẹbi awọn ibeere ti olubẹwẹ, awọn idanwo miiran ti kii ṣe iparun le ṣafikun lẹhin idunadura laarin olupese ati olubẹwẹ ati itọkasi ninu adehun naa.

Idanwo ipata intergranular

Idanwo ipata intergranular yoo ṣee ṣe fun paipu irin alagbara (sooro ooru). Ọna idanwo naa yoo wa ni ibamu pẹlu awọn ipese ti ọna Kannada E ni GB / T 4334-2008, ati pe a ko gba laaye iṣesi ipata intergranular lẹhin idanwo naa.

Lẹhin idunadura laarin olupese ati olubẹwẹ, ati akiyesi ninu adehun, olubẹwẹ le ṣe apẹrẹ awọn ọna idanwo ipata miiran.