I-Seamless yensimbi yamapayipi wensimbi Okuqukethwe kuvame ukwenziwa ngensimbi esezingeni eliphakeme yekhabhoni enjenge-10,20, 30, 35,45, insimbi ephansi ye-alloy enjengeI-16MN, I-5mNV noma insimbi ye-alloy enjenge-40cr, 30crmnsi, 45mn2, 40mbb ngokuhamba okushisayo noma ukugoqa okubandayo. Amapayipi angenamthungo enziwe ngensimbi ephansi yekhabhoni efana ne-10 no-20 asetshenziselwa amapayipi okulethwa koketshezi.

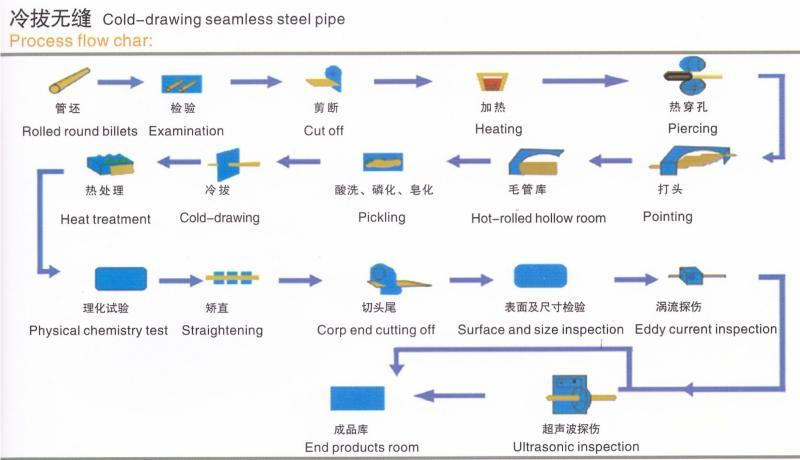

Imvamisa, inqubo yokukhiqiza yamapayipi ensimbi angenamthungo ihlukaniswe ngezinhlobo ezimbili: inqubo yokudweba ebandayo nenqubo eshisayo yokugoqa. Lokhu okulandelayo kungukubuka konke kwenqubo ukugeleza kwamapayipi ensimbi adonswe amakhaza kanye namapayipi ensimbi ashushulule eshisayo:

Inqubo edonswe ebandayo (ebandayo) Inqubo yensimbi engenamthungo: Ukulungiselela ishubhu

Amabhilidi wepayipi elibandayo angenawo amakhaza kumele aqale akhishwe ngaphansi kokugoqa okuthathu okuqhubekayo, nokuhlolwa kokulinganisa kufanele kwenziwe ngemuva kokukhishwa. Uma kungekho ukuqhekeka kwempendulo ebusweni, ishubhu eliyindilinga kumele linqunywe ngumshini wokusika bese usika kwizigidigidi ngobude obungamamitha owodwa. Bese ufaka inqubo yokunxusa. I-Anneling kumele ifakwe ngoketshezi olune-acidic. Ngesikhathi sokuthathwa, naka ukuthi kunenani elikhulu lama-bubble ebusweni. Uma kunenani elikhulu lama-bubble, kusho ukuthi ikhwalithi yepayipi lensimbi ayihlangabezani namazinga ahambisanayo.

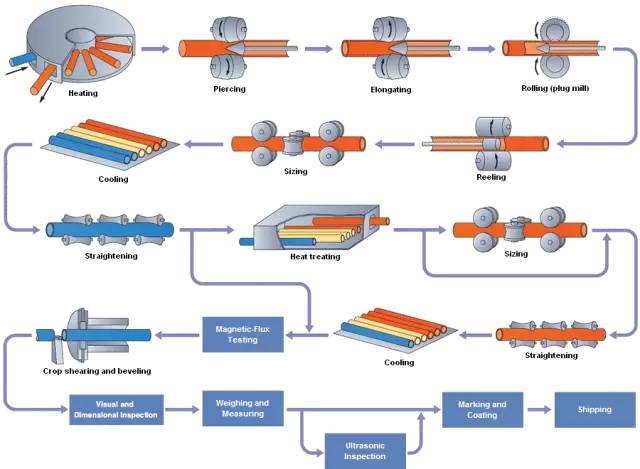

Inqubo evuthayo eshisayo (ekhishwe phansi) yensimbi engenamthungo

Ukujikeleza okushisayo, njengoba igama lisho, linokushisa okuphezulu kwengcezu egoqiwe, ngakho-ke ukumelana nokuchazwa kuncane futhi inani elikhulu lokukhubazeka lingatholakala. Isimo sokulethwa kwamapayipi ensimbi asongelwe esishisayo ngokuvamile asongelwa futhi aphathwe ukushisa ngaphambi kokulethwa. Ishubhu eliqinile liyahlolwa futhi liyasuswa iziphambeko ezingaphezulu, zinqunywe ngobude obudingekayo, zigxile ebusweni bokuphela kokuphela okuhlanganisiwe kwe-tube, bese kuthunyelwa esithandweni sokufudumeza ukufudumeza. Ngenkathi kunqoba, kuyajikeleza futhi kuqhubekela phambili ngokuqhubekayo. Ngaphansi kwesenzo sama-roller kanye nekhanda, kancane kancane amafomu angaphakathi kwe-tube, ebizwa ngokuthi yi-tube enolaka. Ngemuva kokuthi ithubhu lisusiwe, lithunyelwa emshinini ozenzakalelayo we-Tube Rolling ukuze uqhubeke ngokugoqa, bese ububanzi bodonga buyalungiswa ngumshini wokulinganisa, bese ububanzi bunqunywa ngumshini wokulinganisa ukuze uhlangabezane nezidingo zokucaciswa. Ngemuva kokwelashwa okushisayo okushisayo, ukuhlolwa kokunye okumele kwenziwe. Uma ububanzi be-blodunation bukhulu kakhulu, kufanele buqonde futhi balungiswe, futhi ekugcineni babhalwe futhi babhalwe phansi.

Ukuqhathaniswa kwenqubo yokudweba ebandayo nenqubo eshisayo yokugoqa: Inqubo yokugoqa okubandayo iyinkimbinkimbi kakhulu kunenqubo eshisayo yokugoqa, kepha ikhwalithi ephezulu yamapuleti ensimbi ebandayo ingcono kunaleyo yamapuleti asongwe avuthiwe, futhi ubukhulu bomkhiqizo bungaba mncane.

Ubukhulu: Ububanzi obungaphandle wepayipi elingenamthungo elishisayo ngokuvamile bukhulu kune-32mm, futhi ubukhulu bodonga bungu-2,200mm. Ububanzi obungaphandle bamaphaphu wensimbi elibandayo elibandayo bungavuka, ububanzi bodonga bungaba ngu-0,5mm, ububanzi obungaphandle bungaphansi kwe-5mm, futhi ukunemba okungamakhaza kungaphansi kwe-0.25mm (ngisho nangaphansi kokunemba okubandayo kuphakeme kunalokho okusongiwe okushisayo.

Ukubukeka: Yize ubukhulu bodonga lwepayipi lensimbi elibandayo elibandayo ngokuvamile buncane kunalolo lwepayipi lensimbi elishisiwe elishisayo, ingaphezulu libukeka likhanya kakhulu kunepayipi elinodonga elishisiwe elishisiwe, ingaphezulu lelo alilona libi kakhulu.

Isimo Sokulethwa: Kuthunyelwa Amapayipi ensimbi eshisayo ngesimo esigoqiwe noma aphathwe ngokushisa, futhi amapayipi ensimbi agoqayo alethwa esimweni esiphathwa ukushisa.

Isikhathi Sokuthumela: Aug-21-2024