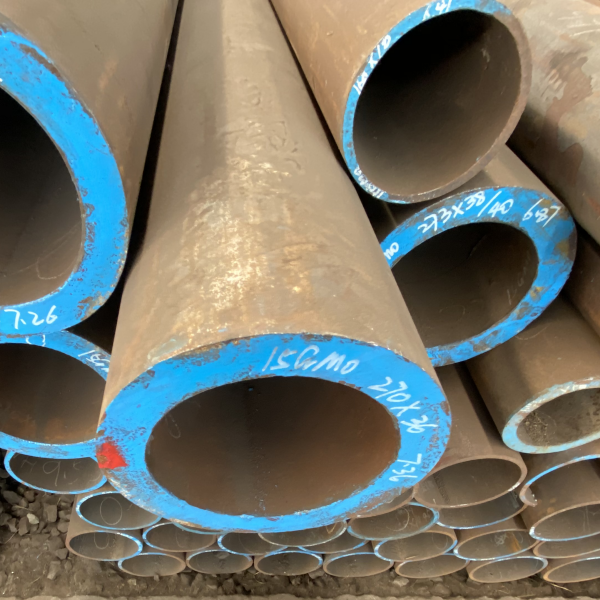

Amashubhu wensimbi engenamthungo yokuqhekeka kaphethiloli, GB9988-2006, Sanon Pipe

| Okujwayelekile:GB9948-2006 | Ukwelashwa kokushisa: ukunxusa / okujwayelekile / ukulangazelela |

| Iqembu lebanga: 10,12CrMO, 15CRMO, 07CRL9NIL0, njll | Ububanzi obungaphandle (Round): 10 - 1000 mm |

| Ubukhulu: 1 - 100 mm | Isicelo: Amashubhu wokushintshanisa ukushisa |

| Ububanzi obungaphandle (Round): 10 - 1000 mm | Ukwelashwa okungaphezulu: njengemfuneko yekhasimende |

| Ubude: Ubude obuhleliwe noma ubude obuhleliwe | Inqubo: Kuvuselelwa okushisayo |

| Isimo sengxenye: nxazonke | Ipayipi elikhethekile: Ipayipi eliwugqinsi olubanzi |

| Indawo yemvelaphi: China | Ukusetshenziswa: Amashubhu wokushintshanisa ukushisa |

| Ukuqinisekiswa: Iso9001: 2008 | Isivivinyo: Ut / Mt |

Amashubhu wensimbi engenamthungo yokuqhekeka kukaPetroleum asebenza kumashubhu wensimbi engenamthungo yamashubhu wesithando, amashubhu wokushintshanisa namapayipi okucindezela embonini ye-petrochemical.

Amabanga aphezulu we-carbon ahlelekile amabanga aphezulu angama-20G, 20mng no-25mng.

Amamaki ensimbi ehlelekile: 15mog, 20mog, 12crmog

I-15CRMOG, 12CR2MOG, 12CRMOVG, njll

Ibanga lensimbi esezingeni eliphakeme lekhabhoni: 10 #,20 #

Amabanga aphezulu we-Carbon ahlelekile amabanga aphezulu: 20G, 20mng no-25mng

Amamaki ensimbi ehlelekile

| No | Khuphuka | Ingxenye yamakhemikhali% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Insimbi esezingeni eliphakeme yekhabhoni | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Insimbi ye-Alloy Ehlelekile | I-12CrMO | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. Okungama-70 | 0. 40-0. Okungama-70 | 0. 40 -0.55 | <0. Umphobho wamakhasi wamavumthetho | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| I-15CRMO | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. Okungama-70 | 0. 80-1.1 | 0. 40-0.55 | <0. Umphobho wamakhasi wamavumthetho | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| I-12crlmo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. Okucindezelekile kakhulu | 0.45 -0.65 | <0. Umphobho wamakhasi wamavumthetho | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| I-12crlmov | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. Okungama-70 | 0.90-1.2 | 0. 25 -0.35 | <0. Umphobho wamakhasi wamavumthetho | - | - | 0.15 -0 -0. Umphobho wamakhasi wamavumthetho | <0. 20 | 0.025 | 0. 010 | |

| I-12cr2mo | 0.08-0.15 | <0. Okucindezelekile kakhulu | 0. 40-0. Khipha kulokho | 2. 00,-2. Okucindezelekile kakhulu | 0. 90-1.13 | <0. Umphobho wamakhasi wamavumthetho | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| I-12cr5moi | <0.15 | <0. Okucindezelekile kakhulu | 0.30-0.6 | 4. 00-6 | 0. 45 -0. Khipha kulokho | <0. Khipha kulokho | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| I-12cr5mont | |||||||||||||

| I-12cr9moi | <0.15 | 0. 25-1. 00 | 0. 30-0. Khipha kulokho | 8.00 -10. 00 | 0. 90-1.1 | <0. Khipha kulokho | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| I-12cr9mont | |||||||||||||

| Insimbi engapheli yokuvimbela insimbi | I-07CRL9NIL0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8nillnB | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9ndillti | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00 ~ 13. 00 | - | 4c-0. Khipha kulokho | 一 | 一 | 0.03 | 0. 015 | |

| 022CRL7NIL2MO2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

| -Nokuba | -The ngqi I-MPA | Veza I-MPA | I-Elong Ngemuva kokuphuka A /% | I-Shorm Ancresption Energy KV2 / J | Inombolo ye-Brinell Hardness Inombolo | ||

| imidwebo | amaguquline | imidwebo | amaguquline | ||||

| hhayi ngaphansi | akusekho | ||||||

| 10 | 335~475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410 ~550 | 245 | 24 | 22 | 40 | 27 | |

| I-12CrMO | 410 ~560 | 205 | 21 | 19 | 40 | 27 | 156 Hbw |

| I-15CRMO | 440 ~640 | 295 | 21 | 19 | 40 | 27 | 170 Hbw |

| I-12crlmo | I-415 ~560 | 205 | 22 | 20 | 40 | 27 | 163 Hbw |

| I-12crlmov | 470~440 | 255 | 21 | 19 | 40 | 27 | 179 Hbw |

| I-12cr2mo | 450 ~ 600 | I-280 | 22 | 20 | 40 | 27 | 163 Hbw |

| I-12cr5moi | I-415 ~590 | 205 | 22 | 20 | 40 | 27 | 163 Hbw |

| I-12cr5mont | 480~440 | I-280 | 20 | 18 | 40 | 27 | - |

| I-12cr9moi | 460~440 | 210 | 20 | 18 | 40 | 27 | 179 Hbw |

| I-12cr9mont | 590-740 | I-390 | 18 | 16 | 40 | 27 | |

| O7CRL9NILO | 2520 | 205 | 35 | 187 Hbw | |||

| 07Crl8nillnB | > 520 | 205 | 35 | - | 187 Hbw | ||

| 07Crl9ndillti | > 520 | 205 | 35 | - | - | 187 Hbw | |

| 022CRL7NIL2MO2 | > 485 | -Nqobile | 35 | 一 | - | 187 Hbw | |

| Ngensimbi enobukhulu odongeni ngaphansi kwe-5mm tube abenzi ubunzima bokuhlola | |||||||

Ukuhlolwa kwe-Hydraulic

Ukuhlolwa kwe-Hydraulic kuzokwenziwa ngamapayipi ensimbi ngamunye ngamunye. Ingcindezi yokuhlola ephezulu yi-20 MPA. Ngaphansi kwengcindezi yokuhlola, isikhathi sokuqina ngeke sibe ngaphansi kwama-10 s, nokuvuza kwepayipi lensimbi akuvunyelwe.

Ukuhlolwa okumnandi

Ukuhlolwa kwe-Flatening kuzoqhutshwa ngepayipi lensimbi elinobubanzi obungaphandle obukhulu kune-22 mm

Ukuhlolwa komoya

I-Carbon ephezulu yensimbi ehlelekile ne-stainless (engavikeli) amapayipi ensimbi anobubanzi obungaphezulu kwama-76 mm kanye nodonga olungabi ngaphezu kwe-8 mm luzoncika ekuhlolweni. Ukuhlolwa okuvuthayo kuzokwenziwa emazingeni okushisa asekamelweni. I-Outer ububanzi obudabuke izinga lesampula ngemuva kwe-TOP Core Taper kuma-60% okuvutha azohlangabezana nezidingo zethebula 7. Akukho ukuqhekeka noma imifantu evunyelwe kwisampula ngemuva kokuvutha. Ngokwezidingo zesidingo futhi waphawula kwinkontileka, i-alloy ehlelekile ingasetshenziselwa ukwandisa isivivinyo.

I-tento ethandekayo

Amapayipi ensimbi azophansi kokutholwa kwe-FACEAFICION FAFICE ngakunye ngokuya ngezinhlinzeko ze-GB / T 5777-2008-2008. Ngokwezidingo zesidingo, ezinye izivivinyo ezingezona ezonakalisayo zingangezwa ngemuva kokuxoxisana phakathi komphakeli kanye nomfakeli futhi kukhonjiswe kwinkontileka.

Ukuhlolwa kokugqwala kwenhlangano

Ukuhlolwa kokugqwala kwenhlalola kuzokwenziwa ngepayipi elingenasici (elimelana nokushisa). Indlela yokuhlola izohambisana nezinhlinzeko zendlela yesiShayina e ku-GB / T 4334-2008, kanye nokuthambekela kokugqwala kolunye izwe akuvunyelwe ngemuva kokuhlolwa.

Ngemuva kokuxoxisana phakathi komphakeli kanye nomfakisili, futhi kuphawulwe kwinkontileka, umdlali we-Defenting angaqoka ezinye izindlela zokuhlola zokugqwala.

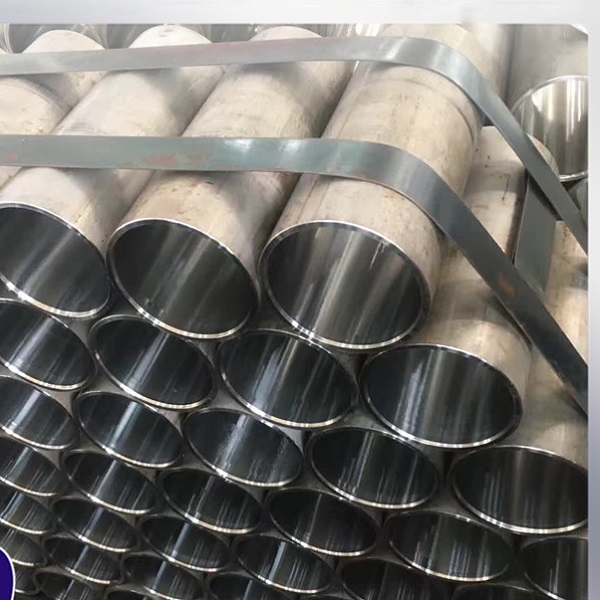

Amafutha, ama-petrochemical, ama-boiler aphezulu wengcindezelo, ukusetshenziswa okukhethekile kwe-seamless Tube Boiler Tube engenamlilo, ishubhu yensimbi ye-geological ephansi kanye ne-tube engenamthungo.

Ingxenye yamakhemikhali

| phawula | Ingxenye yamakhemikhali (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb + ta | S | P | |

| I-15CRMO | 0.12 ~ 0.18 | 0.40 ~ 0.70 | 0.17 ~ 0.37 | 0.80 ~ 1.10 | 0.40 ~ 0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Impahla yemishini

| phawula | -The ngqi I-MPA | Veza I-MPA | I-Elongation (%) |

| I-15CRMO | 440 ~ 640 | 295 | 22 |