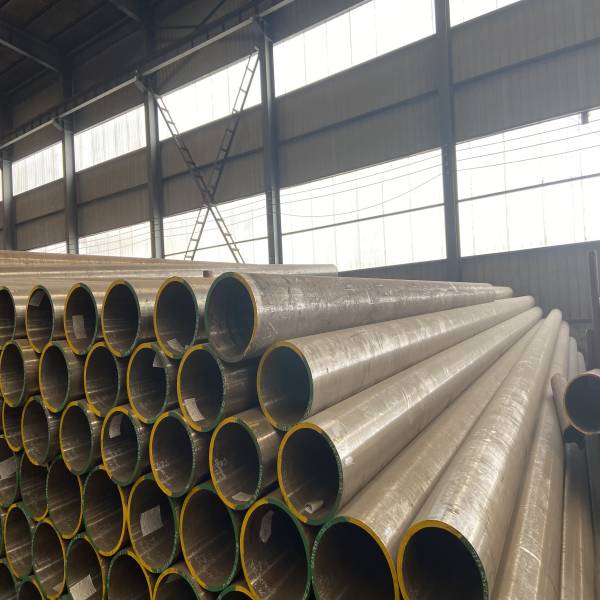

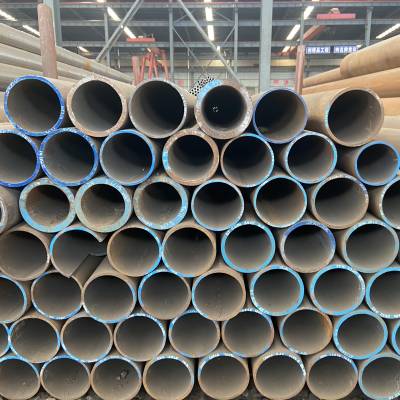

Low MOQ ya Hot Cold Rolled chube ASTM A335 P22 P1 P2 P12 A213 A199 Seamless Alloy Carbon Steel Boiler Pipe

Nthawi zonse timapereka mzimu wathu "Zatsopano zobweretsa chitukuko, Zapamwamba kwambiri kupanga zopezera ndalama, Kutsatsa malonda ndi kutsatsa, Ngongole imakopa ogula a Low MOQ a Hot Cold Rolled Tube ASTM A335 P22 P1 P2 P12 A213 A199 Seamless Alloy Carbon Steel Boiler Pipe , Ubwino wapamwamba udzakhala chinthu chofunikira kwambiri ndi kampani kuti ikhale yosiyana ndi ena omwe akupikisana nawo. Kuwona ndi Kukhulupirira, mukufuna zambiri? Kungoyesa pazogulitsa zake!

Nthawi zonse timapereka mzimu wathu wa "Innovation kubweretsa chitukuko, Kupeza ndalama zapamwamba kwambiri, Kutsatsa kwa Management ndi phindu la malonda, Ngongole imakopa ogulaChina Cold adagulung'undisa Steel Chitoliro ndi Cold adagulung'undisa Zitsulo chubu, kampani yathu chimakwirira kudera la 20, 000 lalikulu mamita. Tili ndi antchito opitilira 200, gulu laukadaulo laukadaulo, zokumana nazo zaka 15, luso lapamwamba, khalidwe lokhazikika komanso lodalirika, mtengo wampikisano komanso mphamvu zokwanira zopangira, umu ndi momwe timapangira makasitomala athu kukhala olimba. Ngati muli ndi mafunso, musazengereze kutilankhula nafe.

Mwachidule

| Mtundu: ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P5, P9, P11, P22, P91, P92 Etc. | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro Chapadera: Chitoliro Chachikulu cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Kugwiritsa ntchito

Amagwiritsidwa ntchito kwambiri popanga chitoliro chapamwamba cha aloyi chitsulo chowotcha, chitoliro chosinthanitsa kutentha, chitoliro champhamvu cha nthunzi chamafuta ndi mafakitale amafuta.

Main Grade

Gulu la chitoliro chapamwamba cha alloy![]() 5,P9,P11,P22,P91,P92 etc

5,P9,P11,P22,P91,P92 etc

Chigawo cha Chemical

| Gulu | UN | C≤ | Mn | P≤ | S≤ | Si≤ | Cr | Mo |

| Sequiv. | ||||||||

| P1 | K11522 | 0.10-0.20 | 0.30-0.80 | 0.025 | 0.025 | 0.10-0.50 | - | 0.44 ~ 0.65 |

| P2 | K11547 | 0.10-0.20 | 0.30-0.61 | 0.025 | 0.025 | 0.10-0.30 | 0.50-0.81 | 0.44 ~ 0.65 |

| P5 | K41545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| p5b | K51545 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.00 ~ 2.00 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| p5c | K41245 | 0.12 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 4.00 ~ 6.00 | 0.44 ~ 0.65 |

| P9 | S50400 | 0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.50-1.00 | 8.00-10.00 | 0.44 ~ 0.65 |

| p11 | K11597 | 0.05-0.15 | 0.30-0.61 | 0.025 | 0.025 | 0.50-1.00 | 1.00 ~ 1.50 | 0.44 ~ 0.65 |

| P12 | K11562 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 0.80 ~ 1.25 | 0.44 ~ 0.65 |

| p15 | K11578 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 1.15-1.65 | - | 0.44 ~ 0.65 |

| p21 | K31545 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 2.65-3.35 | 0.80-1.60 |

| P22 | K21590 | 0.05-0.15 | 0.30-0.60 | 0.025 | 0.025 | 0.5 | 1.90-2.60 | 0.87-1.13 |

| p91 | K91560 | 0.08-0.12 | 0.30-0.60 | 0.02 | 0.01 | 0.20-0.50 | 8.00~9.50 | 0.85-1.05 |

| p92 | K92460 | 0.07-0.13 | 0.30-0.60 | 0.02 | 0.01 | 0.5 | 8.50-9.50 | 0.30-0.60 |

Dzina Latsopano lokhazikitsidwa motsatira Practice E 527 ndi SAE J1086, Practice for Numbering Metals and Alloys (UNS). B Gulu la P 5c lizikhala ndi titaniyamu yosachepera kanayi kuposa kuchuluka kwa kaboni ndipo osapitilira 0.70%; kapena columbium zili ndi 8 mpaka 10 nthawi ya carbon.

Mechanical Property

| Zimango katundu | p1, p2 | P12 | p23 | p91 | P92,P11 | P122 |

| Kulimba kwamakokedwe | 380 | 415 | 510 | 585 | 620 | 620 |

| Zokolola mphamvu | 205 | 220 | 400 | 415 | 440 | 400 |

Kutentha Chithandizo

| Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing kapena Tempering |

| P5, P9, P11, ndi P22 | Kutentha F [C] | ||

| A335 P5 (b,c) | Full kapena Isothermal Anneal | ||

| Normalize ndi Kupsa mtima | ***** | 1250 [675] | |

| Subcritical Anneal (P5c yokha) | ***** | 1325 - 1375 [715 - 745] | |

| A335 P9 | Full kapena Isothermal Anneal | ||

| Normalize ndi Kupsa mtima | ***** | 1250 [675] | |

| A335 P11 | Full kapena Isothermal Anneal | ||

| Normalize ndi Kupsa mtima | ***** | 1200 [650] | |

| A335 P22 | Full kapena Isothermal Anneal | ||

| Normalize ndi Kupsa mtima | ***** | 1250 [675] | |

| A335 P91 | Normalize ndi Kupsa mtima | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

| Chotsani ndi Kutentha | 1900-1975 [1040 - 1080] | 1350-1470 [730 - 800] |

Kulekerera

Pakuti chitoliro analamula kuti m'mimba mwake mkati, m'mimba mwake mkati sizidzasiyana kuposa 6 1% kuchokera mwachindunji m'mimba mwake.

Kusiyanasiyana Kovomerezeka mu Diameter Yakunja

| Wopanga NPS | in | mm | in | mm |

| 1⁄8 mpaka 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Opitilira 8 mpaka 12, kuphatikiza. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | 6 1% ya zomwe zatchulidwa kunja awiri |

Chofunikira Choyesa

Mayeso a Hydraustatic:

Chitoliro Chachitsulo Chiyenera Kuyesedwa Hydraulically Mmodzi Ndi Mmodzi. Kupanikizika Kwambiri Kwambiri Ndi 20 MPa. Pansi pa Kupanikizika kwa Mayesero, Nthawi Yokhazikika Iyenera Kusachepera 10 S, Ndipo Chitoliro Chachitsulo Siyenera Kutayikira.

Pambuyo Wogwiritsa Ntchito Avomera, Mayeso a Hydraulic Atha Kusinthidwa Ndi Mayeso a Eddy Panopa Kapena Mayeso a Magnetic Flux Leakage.

Mayeso Osawononga:

Mipope Yomwe Imafunika Kuyang'ana Kwambiri Iyenera Kuyang'aniridwa Mmodzi Ndi Mmodzi. Pambuyo Kukambitsirana Kumafuna Chivomerezo cha Phwando Ndipo Kufotokozedwa Mumgwirizanowu, Mayeso Ena Osawononga Akhoza Kuwonjezedwa.

Mayeso a Flattening:

Machubu Okhala Ndi Diameter Yakunja Yoposa 22 Mm Adzayesedwa Kusanja. Palibe Delamination Yowoneka, Mawanga Oyera, Kapena Zonyansa Zomwe Ziyenera Kuchitika Pakuyesa Konse.

Mayeso Olimba:

Pa mayeso a kuuma kwa chitoliro cha Magiredi P91, P92, P122, ndi P911, Brinell, Vickers, kapena Rockwell adzapangidwa pachitsanzo chochokera kugawo lililonse.

Bend Test:

Kwa chitoliro chomwe m'mimba mwake chimaposa NPS 25 ndipo kukula kwake kwa chiŵerengero cha khoma ndi 7.0 kapena kucheperapo chidzayesedwa m'malo mwa kuyesa kwa flattening. Chitoliro china chomwe m'mimba mwake chimakhala chofanana kapena kupitirira NPS 10 chikhoza kupatsidwa mayeso opindika m'malo mwa kuyesa kosalala malinga ndi kuvomerezedwa ndi wogula.

Tsatanetsatane wa Zamalonda

Kanema

Boiler Tube

GB/T5310-2017

ASME SA-106/SA-106M-2015

ASTMA210(A210M)-2012

ASME SA-213/SA-213M

ASTM A335/A335M-2018

Nthawi zonse timapereka mzimu wathu "Zatsopano zobweretsa chitukuko, Zapamwamba kwambiri kupanga zopezera ndalama, Kutsatsa malonda ndi kutsatsa, Ngongole imakopa ogula a Low MOQ a Hot Cold Rolled Tube ASTM A335 P22 P1 P2 P12 A213 A199 Seamless Alloy Carbon Steel Boiler Pipe , Ubwino wapamwamba udzakhala chinthu chofunikira kwambiri ndi kampani kuti ikhale yosiyana ndi ena omwe akupikisana nawo. Kuwona ndi Kukhulupirira, mukufuna zambiri? Kungoyesa pazogulitsa zake!

Low MOQ kwaChina Cold adagulung'undisa Steel Chitoliro ndi Cold adagulung'undisa Zitsulo chubu, kampani yathu chimakwirira kudera la 20, 000 lalikulu mamita. Tili ndi antchito opitilira 200, gulu laukadaulo laukadaulo, zokumana nazo zaka 15, luso lapamwamba, khalidwe lokhazikika komanso lodalirika, mtengo wampikisano komanso mphamvu zokwanira zopangira, umu ndi momwe timapangira makasitomala athu kukhala olimba. Ngati muli ndi mafunso, musazengereze kutilankhula nafe.

Chithunzi cha ASTM A335 P5ndi aloyi zitsulo zopanda msokonezo ferritic kutentha chitoliro cha American muyezo. Aloyi chubu ndi mtundu wa chubu zitsulo zopanda msokonezo, ntchito yake ndi yokwera kwambiri kuposa chubu chachitsulo chosasunthika, chifukwa chubu chachitsulo chamtunduwu chimakhala ndi C zambiri, magwiridwe antchito ake ndi ocheperako kuposa chubu wamba wopanda chitsulo, motero chubu cha aloyi chimagwiritsidwa ntchito kwambiri. mu petroleum, ndege, mankhwala, mphamvu yamagetsi, boiler, asilikali ndi mafakitale ena.

Chitoliro cha Alloy Steel chili ndi zinthu zina zambiri kupatula kaboni monga faifi tambala, chromium, silicon, manganese, tungsten, molybdenum, vanadium ndi zinthu zina zovomerezeka monga manganese, sulfure, silicon, ndi phosphorous.

Zogwirizana ndi aloyi zitsulo zapakhomo: 1Cr5Mo GB 9948-2006 "Chitsulo Chopanda Chitsulo Chokhazikika cha Kuphwanya Mafuta"

- Malipiro: 30% Deposit, 70% L/C Kapena B/L Copy Kapena 100% L/C Pamaso

- Min.Kulamula Kuchuluka: 1 PC

- Kutha Kupereka: Pachaka 20000 Tons Inventory Of Steel Pipe

- Nthawi Yotsogola: Masiku a 7-14 Ngati Muli Sitolo, Masiku 30-45 Opanga

- Kulongedza: Kutha Kwakuda, Bevel Ndi Cap Paipi Iliyonse Limodzi; OD Pansi pa 219mm Ayenera Kulongedza Mtolo, Ndipo Mtolo Uliwonse Osapitirira 2 Matani.

Mwachidule

| Zokhazikika:Chithunzi cha ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P5 | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro Chapadera: Chitoliro Chachikulu cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Kugwiritsa ntchito

Amagwiritsidwa Ntchito Kwambiri Kupanga Chitoliro Chowiritsira Chachitsulo Chokwera Kwambiri, Chitoliro Chosinthanitsa ndi Kutentha, Chitoliro Champhamvu Chokwera cha Mpweya wa Mafuta ndi Makampani a Chemical.

Chigawo cha Chemical

| Zolemba | Zambiri |

| Kupanga kwa UNS | K41545 |

| Mpweya (max.) | 0.15 |

| Manganese | 0.30-0.60 |

| Phosphorus (max.) | 0.025 |

| Silikoni (max.) | 0.50 |

| Chromium | 4.00-6.00 |

| Molybdenum | 0.45-0.65 |

| Zinthu Zina | … |

Mechanical Property

| Katundu | Zambiri |

| Kulimbitsa Mphamvu, Min, (MPa) | 415 pa |

| Yield Strength, Min, (MPa) | 205 Mpa |

| Elongation, Min, (%), L/T | 30/20 |

Kutentha Chithandizo

| Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing Kapena Kutentha |

| P5, P9, P11, ndi P22 | Kutentha F [C] | ||

| A335 P5 (B,C) | Full Kapena Isothermal Anneal | ||

| A335 P5b | Normalize And Temper | ***** | 1250 [675] |

| A335 P5c | Subcritical Anneal | ***** | 1325 - 1375 [715 - 745] |

Kulekerera

Kwa Chitoliro Cholamulidwa Kuti Chikhale M'kati mwa Diameter, Diameter Yam'kati Siyenera Kusiyanasiyana Kuposa ± 1% Kuchokera M'kati Mwa Diameter Yotchulidwa.

Kusiyanasiyana Kovomerezeka Mu Diameter Yakunja

| Wopanga NPS | Kulekerera kwabwino | kulolerana koipa | ||

| In | Mm | In | Mm | |

| 1⁄8to 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Kupitilira 8 mpaka 12, Inc. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | ± 1% ya Zomwe Zatchulidwa Kunja Diameter | |||

Chofunikira Choyesa

Mayeso a Hydraustatic:

Chitoliro Chachitsulo Chiyenera Kuyesedwa Hydraulically Mmodzi Ndi Mmodzi. Kupanikizika Kwambiri Kwambiri Ndi 20 MPa. Pansi pa Kupanikizika kwa Mayesero, Nthawi Yokhazikika Iyenera Kusachepera 10 S, Ndipo Chitoliro Chachitsulo Siyenera Kutayikira.

Pambuyo Wogwiritsa Ntchito Avomera, Mayeso a Hydraulic Atha Kusinthidwa Ndi Mayeso a Eddy Panopa Kapena Mayeso a Magnetic Flux Leakage.

Mayeso Osawononga:

Mipope Yomwe Imafunika Kuyang'ana Kwambiri Iyenera Kuyang'aniridwa Mmodzi Ndi Mmodzi. Pambuyo Kukambitsirana Kumafuna Chivomerezo cha Phwando Ndipo Kufotokozedwa Mumgwirizanowu, Mayeso Ena Osawononga Akhoza Kuwonjezedwa.

Mayeso a Flattening:

Machubu Okhala Ndi Diameter Yakunja Yoposa 22 Mm Adzayesedwa Kusanja. Palibe Delamination Yowoneka, Mawanga Oyera, Kapena Zonyansa Zomwe Ziyenera Kuchitika Pakuyesa Konse.

Mayeso Olimba:

Kwa Pipe Of Giredi P91, P92, P122, Ndi P911, Brinell, Vickers, Kapena Rockwell Hardness Mayeso Adzapangidwa Pachitsanzo cha Loti Iliyonse.

Bend Test:

Kwa Pipe Yemwe Diameter Yake Imapitilira NPS 25 Ndipo Yemwe Kukula Kwake Kwa Khoma Ndi 7.0 Kapena Kuchepera Idzaperekedwa Kuyesedwa Kwa Bend M'malo Mwa Kuyesa Kwa Flattening. Chitoliro China Chomwe Diameter Yake Imafanana Kapena Kupitilira NPS 10 Itha Kupatsidwa Mayeso a Bend M'malo Oyesa Osalala Pansi Pakuvomerezedwa ndi Wogula.

Zida & Kupanga

Chitoliro chikhoza kukhala chotentha chomaliza kapena chozizira chokokedwa ndi kumalizidwa kwa kutentha komwe kwalembedwa pansipa.

Kutentha Chithandizo

- A/N+T

- N+T/Q+T

- N+T

Mayeso a Makina Ofotokozedwa

- Mayeso a Transverse kapena Longitudinal Tension Test and Flattening Test, Hardness Test, kapena Bend Test

- Pa kutentha kwa zinthu zomwe zimatenthedwa mu ng'anjo yamtundu wa batch, mayeso amayenera kuyesedwa pa 5% ya chitoliro kuchokera pagawo lililonse lomwe lakonzedwa. Pazigawo zing'onozing'ono, chitoliro chimodzi chiyenera kuyesedwa.

- Kwa kutentha kwazinthu zomwe zimachitidwa ndi ndondomeko yopitilira, mayesero adzayesedwa pa chitoliro chokwanira kuti apange 5% ya maere, koma osachepera 2 chitoliro.

Ndemanga za Bend Test:

- Kwa chitoliro chomwe m'mimba mwake chimaposa NPS 25 ndipo kukula kwake kwa chiŵerengero cha khoma ndi 7.0 kapena kucheperapo chidzayesedwa m'malo mwa kuyesa kwa flattening.

- Chitoliro china chomwe m'mimba mwake chimakhala chofanana kapena kupitirira NPS 10 chikhoza kuyesedwa m'malo mwa kuyesa kwa flatten malinga ndi chilolezo cha wogula.

- Zitsanzo zoyeserera za bend ziyenera kupindika kutentha kwa 180 popanda kusweka kunja kwa gawo lopindika.

AChithunzi cha STM A335 P5machubu achitsulo osasunthika ndi oyenera madzi, nthunzi, haidrojeni, mafuta owawasa, etc. Ngati amagwiritsidwa ntchito ngati nthunzi yamadzi, kutentha kwake kwakukulu ndi 650.℃; Akagwiritsidwa ntchito m'malo ogwirira ntchito monga mafuta wowawasa, amakhala ndi kutentha kwapamwamba kwa sulfure kukana, ndipo amagwiritsidwa ntchito nthawi zambiri pakutentha kwambiri kwa sulfure 288 ~ 550.℃.

Njira yopangira:

1. Kugudubuza kotentha (chubu chachitsulo chosakanizidwa chotuluka) : chubu chozungulira → kutenthetsa → choboola → chopiringizira chopingasa katatu, kugudubuza mosalekeza → kuvula machubu → kukula (kapena kuchepetsa) → kuzirala → kuwongola → kuyesa kuthamanga kwamadzi (kapena kuzindikira kuti pali vuto ) → kuyika chizindikiro → kusungirako

2. Kujambula kozizira (kugudubuza) chubu chachitsulo chosasunthika: chubu chozungulira → chotenthetsera → choboola → mutu → kupukuta → pickling → kupaka mafuta (chophimba chamkuwa) → chojambula chozizira chambiri (kugudubuza kozizira) → chubu chopanda kanthu → chithandizo cha kutentha → kuwongola → madzi kuyesa kwamphamvu (kuzindikira zolakwika) → kuyika chizindikiro → kusungirako

Kagwiritsidwe Ntchito:

M'zida zam'mlengalenga ndi vacuum zopangira mafuta a sulfure apamwamba kwambiri,Chithunzi cha ASTM A335 P5machubu achitsulo osasunthika amagwiritsidwa ntchito makamaka pamapaipi apansi a nsanja zam'mlengalenga ndi vacuum, machubu ang'anjo am'mlengalenga ndi ng'anjo za vacuum, magawo othamanga kwambiri amizere yosinthira mumlengalenga ndi vacuum ndi mapaipi ena otentha kwambiri amafuta ndi gasi okhala ndi sulfure.

M'magulu a FCC,Chithunzi cha ASTM A335 P5machubu achitsulo osasunthika amagwiritsidwa ntchito makamaka pakutentha kwambiri, chothandizira komanso mapaipi oyenga, komanso mapaipi ena otenthetsera kwambiri amafuta a sulfure ndi gasi.

Pakuchedwa kophika unit,Chithunzi cha ASTM A335 P5Chitoliro chachitsulo chosasunthika chimagwiritsidwa ntchito kwambiri popangira chitoliro chapamwamba cha kutentha pansi pa nsanja ya coke ndi kutentha kwamafuta ndi chitoliro cha gasi pamwamba pa nsanja ya coke, chitoliro cha ng'anjo pansi pa ng'anjo ya coke, chitoliro pansi pa nsanja ya fracking ndi zina. kutentha kwakukulu kwa mafuta ndi chitoliro cha gasi chokhala ndi sulfure.

Chitoliro cha Alloy Steel chili ndi zinthu zina zambiri kupatula kaboni monga faifi tambala, chromium, silicon, manganese, tungsten, molybdenum, vanadium ndi zinthu zina zovomerezeka monga manganese, sulfure, silicon, ndi phosphorous..

Chithunzi cha ASTM A3359 ndi aloyi zitsulo zopanda msokonezo ferritic kutentha chitoliro cha American muyezo. Aloyi chubu ndi mtundu wa chubu zitsulo zopanda msokonezo, ntchito yake ndi yokwera kwambiri kuposa chubu chachitsulo chosasunthika, chifukwa chubu chachitsulo chamtunduwu chimakhala ndi C zambiri, magwiridwe antchito ake ndi ocheperako kuposa chubu wamba wopanda chitsulo, motero chubu cha aloyi chimagwiritsidwa ntchito kwambiri. mu petroleum, ndege, mankhwala, mphamvu yamagetsi, boiler, asilikali ndi mafakitale ena.

A335 P9ndi kutentha kwambiri kwa chromium-molybdenum alloy heat resistant steel opangidwa molingana ndi American standard. Chifukwa cha kukana kwambiri makutidwe ndi okosijeni, mkulu kutentha mphamvu ndi kukana dzimbiri sulfide, chimagwiritsidwa ntchito kutentha ndi kuthamanga kwambiri kuyaka ndi kuphulika mapaipi a mafuta kuyenga zomera, makamaka kutentha chitoliro cha Kutentha ng'anjo, sing'anga kutentha kufika 550 ~ 600 ℃ .

Zogwirizana ndi aloyi zitsulo zapakhomo: 1Cr5Mo GB 9948-2006 "Chitsulo Chopanda Chitsulo Chokhazikika cha Kuphwanya Mafuta"

Mwachidule

| Zokhazikika:Chithunzi cha ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P9 | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro chapadera: Chitoliro Cholimba cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Chigawo cha Chemical

Mankhwala opangidwa ndi mipope yachitsulo yopanda msoko kuti aphwanye mafuta

| Chithunzi cha ASTM A335M | C | SI | Mn | P | S | Cr | Mo |

| P9 | ≦0.15 | 0.25-1.00 | 0.30-0.60 | ≦0.025 | ≦0.025 | 8.00-10.00 | 0.90-1.10 |

Mechanical Property

| Katundu | Zambiri |

| Mphamvu zolimba, min, (MPa) | 415 pa |

| Mphamvu zokolola, min, (MPa) | 205 Mpa |

| Elongation, min, (%), L/T | 14 |

| HB | 180 |

Kutentha Chithandizo

|

Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing Kapena Kutentha |

| P5, P9, P11, ndi P22 | |||

| A335 P9 | Full Kapena Isothermal Anneal | ||

| Normalize And Temper | ***** | 1250 [675] |

A335 P9imatha kutenthedwa ndi kutentha kapena kuzizira + njira zowotcha. Annealing ndondomeko kuzirala liwiro ndi pang'onopang'ono, bwanji kangope kupanga, ndondomeko kupanga n'zovuta kulamulira, ndi kukwera mtengo; Choncho, kupanga kwenikweni kawirikawiri ntchito annealing kutentha mankhwala ndondomeko, nthawi zambiri ntchito normalizing + tempering kutentha mankhwala m'malo annealing ndondomeko, kukwaniritsa kupanga mafakitale.

A335 P9zitsulo chifukwa mulibe V, Nb ndi zinthu zina microalloying, motero kutentha normalizing kuposa A335 P91 zitsulo ndi m'munsi, 950 ~ 1050 ℃, gwirani 1h, ndondomeko pamene normalizing ambiri a carbide kusungunuka koma palibe kukula zoonekeratu tirigu, koma kwambiri kutentha normalizing sachedwa austenite tirigu coarse: tempering kutentha ndi 740-790 ℃, kuti apeze kuuma m'munsi, tempering kutentha nthawi ayenera moyenerera anawonjezera.

Kulekerera

Kwa Chitoliro Cholamulidwa Kuti Chikhale M'kati mwa Diameter, Diameter Yam'kati Siyenera Kusiyanasiyana Kuposa ± 1% Kuchokera M'kati Mwa Diameter Yotchulidwa.

Kusiyanasiyana Kovomerezeka Mu Diameter Yakunja

| Wopanga NPS | Kulekerera kwabwino | kulolerana koipa | ||

| In | Mm | In | Mm | |

| 1⁄8to 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Kupitilira 8 mpaka 12, Inc. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | ± 1% ya Zomwe Zatchulidwa | |||

Njira yopangira:

A335 lakonzedwa malinga ndi udindo zida za Tianjin zitsulo chitoliro ndi makhalidwe aA335 P9chitsulo P9 kuyesa-kupanga ndondomeko ya seamless zitsulo chitoliro:Kupanga zitsulo za ng'anjo yamagetsi → kuyenga ladle → vacuum degassing → kuponyera kufa → kufota kopanda kanthu → kutsekera kopanda kanthu → kutenthetsa kopanda kanthu → kuboola kopanda kanthu → kuboola kozungulira → PQF chubu yopitilira mphero kugudubuza → kukula kwa mipukutu itatu → kuziziritsa kwa bedi lozizirira kudula → kuwongola chitoliro chachitsulo → kuzindikira kutayikira kwa maginito → chithandizo cha kutentha → kuwongola → kuzindikira zolakwika za akupanga → kuyesa kwa hydraulic → kukula ndi kuyang'anira mawonekedwe →kusungirako.

kupanga ndondomeko:

| Nambala yachinthu | kupanga ndondomeko | Zochita ndi Kuwongolera Ubwino | |||

| 1 | Msonkhano woyenderatu | Mphindi za msonkhano | |||

| 2 | Chithunzi cha ASEA-SKF | Sinthani kapangidwe ka mankhwala | |||

| *Kusanthula kapangidwe ka mankhwala | |||||

| *kutentha kwamphamvu | |||||

| 3 | CCM | billet | |||

| 4 | Kuyang'anira zopangira | Kuwunika kopanda kanthu ndi kutsimikizira zaubwino | |||

| *Mawonekedwe: Pamwamba pa billet sayenera kukhala ndi zolakwika monga zipsera, slag, pinholes, ming'alu, ndi zina zotero. Zolemba, zibowo ndi maenje zisapitirire 2.5mm | |||||

| 5 | Kutentha kopanda kanthu | Kutenthetsa ma billets mu ng'anjo yozungulira | |||

| *Kuwongolera kutentha kwa kutentha | |||||

| 6 | kuphulika kwa chitoliro | kuboola ndi kalozera/mbale yowongolera | |||

| *Yesetsani kutentha poboola | |||||

| * Sinthani kukula pambuyo pakuboola | |||||

| 7 | Kutentha Kwambiri | Kutentha kwapang'onopang'ono m'machubu osalekeza | |||

| * Khazikitsani makulidwe a khoma la chitoliro | |||||

| 8 | Kukula | Lamulirani m'mimba mwake ndi makulidwe a khoma | |||

| * Makina athunthu akunja awiri | |||||

| * Complete khoma makulidwe Machining | |||||

| 9 | mankhwala opangidwa | Kusanthula kwa mankhwala | |||

| * Njira zovomerezera za kapangidwe ka mankhwala. Zotsatira za kusanthula kwa mankhwala ziyenera kulembedwa m'buku lazinthu. | |||||

| 10 | Normalizing + Kutentha | Kutentha mankhwala (normalizing) ikuchitika pambuyo otentha anagubuduza. Kutentha mankhwala ayenera kulabadira kulamulira kutentha ndi nthawi. | |||

| Pambuyo pa chithandizo cha kutentha, makina a chinthucho ayenera kukwaniritsa muyezo wa ASTM A335 | |||||

| 11 | kuziziritsa mpweya | Bedi lozizirira pang'onopang'ono | |||

| 12 | kucheka | Kucheka mpaka kutalika kwake | |||

| * Kuwongolera kutalika kwa chitoliro chachitsulo | |||||

| 13 | Kuwongoka (ngati kuli kofunikira) | Amalamulira flatness. | |||

| Pambuyo kuwongola, kuwongoka kuyenera kukhala kogwirizana ndi ASTM A335 | |||||

| 14 | Kuyang'anira ndi Kuvomereza | Maonekedwe ndi Dimensional Inspection | |||

| *Kulolera kwazitsulo kuyenera kukhala kogwirizana ndi ASTM A999 | |||||

| Zindikirani: Kulekerera kwapakati: ± 0.75%D | |||||

| * Kuyang'anira mawonekedwe kuyenera kuchitidwa m'modzi ndi m'modzi malinga ndi muyezo wa ASTM A999 kuti apewe kusauka | |||||

| 15 | kuzindikira zolakwika | *Thupi lonse la chitsulo chitoliro ayenera ultrasonically anayendera longitudinal zolakwika malinga ISO9303/E213 | |||

| Mayeso a Ultrasonic: | |||||

| 16 | Mayeso a katundu wamakina | (1) Mayesero a Tensile (longitudinal) ndi kuyesa kwa flattening | |||

| Kuyendera pafupipafupi | 5% / batch, osachepera 2 machubu | ||||

| Min | Max | ||||

| P9 | Yield Strength (Mpa) | 205 | |||

| tensile mphamvu (MPa) | 415 | ||||

| Elongation | Malinga ndi ASTM A335 muyezo | ||||

| Kuyesa kosalala | Malinga ndi ASTM A999 muyezo | ||||

| (2) Mayeso olimba | |||||

| Kuchuluka kwa mayeso: zofanana ndi kuyesa kwamphamvu | 1 chidutswa/mgulu | ||||

| HV&HRC | ≤250HV10&≤25 HRC HV10≤250&HRC≤25 | ||||

| Zindikirani: Vickers kuuma mayeso muyezo: ISO6507 kapena ASTM E92; | |||||

| Rockwell kuuma muyeso: ISO6508 kapena ASTM E18 | |||||

| 17 | NDT | Chitoliro chilichonse chachitsulo chidzayesedwa malinga ndi zofunikira za njira zoyesera E213, E309 kapena E570. | |||

| 18 | kuyezetsa kuthamanga kwa madzi | Kuyesa kwa Hydrostatic malinga ndi ASTM A999, kukakamizidwa koyesa | |||

| 19 | bevel | Beveling yovomerezeka ya malekezero onse a chitoliro chachitsulo malinga ndi ASTM B16.25fig.3 (a) | |||

| 20 | Kuyeza kulemera ndi kutalika | *Kulemera kamodzi kokha: -6% ~ +4%. | |||

| 21 | Chitoliro muyezo | Kunja kwa chitoliro chachitsulo kudzakhala kupopera chizindikiro malinga ndi ASTM A335 muyezo komanso zofunikira zamakasitomala. Zomwe zili m'malemba ndi izi: | |||

| "Kulemera kwa Utali TPCO ASTM A335 Chaka-Mwezi Miyezo P9 S LT**C ***MPa/NDE Nambala Yotentha Nambala Loti Nambala ya Tube | |||||

| 22 | utoto | Kunja kwa chubu ndi utoto molingana ndi muyezo wa fakitale | |||

| 23 | kapu yomaliza ya bomba | **Payenera kukhala zisoti zapulasitiki kumapeto kwa chubu chilichonse | |||

| 24 | mndandanda wazinthu | *Buku lazinthu liyenera kuperekedwa malinga ndi EN10204 3.1. "PO yamakasitomala iyenera kuwonetsedwa m'buku lazinthu. | |||

Chithunzi cha ASTM A33511 ndi aloyi zitsulo zopanda msokonezo ferritic kutentha chitoliro cha American muyezo. Aloyi chubu ndi mtundu wa chubu zitsulo zopanda msokonezo, ntchito yake ndi yokwera kwambiri kuposa chubu chachitsulo chosasunthika, chifukwa chubu chachitsulo chamtunduwu chimakhala ndi C zambiri, magwiridwe antchito ake ndi ocheperako kuposa chubu wamba wopanda chitsulo, motero chubu cha aloyi chimagwiritsidwa ntchito kwambiri. mu petroleum, ndege, mankhwala, mphamvu yamagetsi, boiler, asilikali ndi mafakitale ena.

Mwachidule

| Zokhazikika:Chithunzi cha ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P11 | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro chapadera: Chitoliro Cholimba cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Chigawo cha Chemical

Mankhwala opangidwa ndi mipope yachitsulo yopanda msoko kuti aphwanye mafuta

| C | SI | Mn | P | S | Cr | Mo | |

| p11 | 0.05-0.15 | 0.5-1.00 | 0.30-0.61 | 0.025 | 0.025 | 1.00-1.50 | 0.44-0.65 |

Mechanical Property

| Katundu | Zambiri |

| Mphamvu zolimba, min, (MPa) | 415 Mpa |

| Mphamvu zokolola, min, (MPa) | 205Mpa |

Kutentha Chithandizo

|

Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing Kapena Kutentha |

| P5, P9, P11, ndi P22 | |||

| A335 P11 | Full Kapena Isothermal Anneal | ||

| Normalize And Temper | ***** | 1250[650] |

Kulekerera

Kwa Chitoliro Cholamulidwa Kuti Chikhale M'kati mwa Diameter, Diameter Yam'kati Siyenera Kusiyanasiyana Kuposa ± 1% Kuchokera M'kati Mwa Diameter Yotchulidwa.

Kusiyanasiyana Kovomerezeka Mu Diameter Yakunja

| Wopanga NPS | Kulekerera kwabwino | kulolerana koipa | ||

| In | Mm | In | Mm | |

| 1⁄8to 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Kupitilira 8 mpaka 12, Inc. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | ± 1% ya Zomwe Zatchulidwa | |||

Chithunzi cha ASTM A335 P22ndi chitoliro chosasunthika chachitsulo chachitsulo chogwiritsa ntchito kutentha kwambiri kwa ferritic. Aloyi chubu ndi mtundu wa chubu zitsulo zopanda msokonezo, ntchito yake ndi yokwera kwambiri kuposa chubu chachitsulo chosasunthika, chifukwa chubu chachitsulo chamtunduwu chimakhala ndi C zambiri, magwiridwe antchito ake ndi ocheperako kuposa chubu wamba wopanda chitsulo, motero chubu cha aloyi chimagwiritsidwa ntchito kwambiri. mu petroleum, ndege, mankhwala, mphamvu yamagetsi, boiler, asilikali ndi mafakitale ena.

Mwachidule

| Zokhazikika:Chithunzi cha ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P22 | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro chapadera: Chitoliro Cholimba cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Chigawo cha Chemical

Mankhwala opangidwa ndi mipope yachitsulo yopanda msoko kuti aphwanye mafuta

| C | SI | Mn | P | S | Cr | Mo | |

| P22 | 0.05-0.15 | 0.5 | 0.30-0.60 | 0.025 | 0.025 | 1.90-2.60 | 0.87-1.13 |

Mechanical Property

| Katundu | Zambiri |

| Mphamvu zolimba, min, (MPa) | 415 Mpa |

| Mphamvu zokolola, min, (MPa) | 205Mpa |

Kutentha Chithandizo

|

Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing Kapena Kutentha |

| P5, P9, P11, ndi P22 | |||

| A335 P22 | Full Kapena Isothermal Anneal | ||

| Normalize And Temper | ***** | 1250[650] |

Kulekerera

Kwa Chitoliro Cholamulidwa Kuti Chikhale M'kati mwa Diameter, Diameter Yam'kati Siyenera Kusiyanasiyana Kuposa ± 1% Kuchokera M'kati Mwa Diameter Yotchulidwa.

Kusiyanasiyana Kovomerezeka Mu Diameter Yakunja

| Wopanga NPS | Kulekerera kwabwino | kulolerana koipa | ||

| In | Mm | In | Mm | |

| 1⁄8to 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Kupitilira 8 mpaka 12, Inc. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | ± 1% ya Zomwe Zatchulidwa | |||

A335 P22 ndi 2.25Cr-1Mo Chromium-molybdenum mkulu Kutentha ferritic chitsulo kwa boilers ndi superheaters,ASTM A335/A335Mmuyezo. Mu 1985, idasinthidwa kukhala GB5310 ndikutchedwa 12Cr2MoG. Mayiko ena ali ndi zitsulo zofanana, monga Federal Republic of Germany 10CrMo910 ndi Japan STBA24. Mu mndandanda wazitsulo wa cr-1Mo, mphamvu yake yotentha imakhala yokwera kwambiri, pansi pa kutentha komweko (kutentha≤580℃) mphamvu zake zosweka ndi kupsinjika kovomerezeka ndizokwera kwambiri kuposa chitsulo cha 9CR-1Mo, ndipo ili ndi magwiridwe antchito abwino komanso kuwotcherera, pulasitiki yabwino yokhazikika. Chifukwa chake, yakhala ikugwiritsidwa ntchito kwambiri m'malo ovuta kwambiri, monga mphamvu yamafuta, mphamvu ya nyukiliya ndi zida zina za haidrojeni m'mapaipi osiyanasiyana otenthetsera komanso zotengera zothamanga kwambiri.

Chovomerezeka kutentha: A335P22 (SA-213T22) zimagwiritsa ntchito 300,600MW ndi zina lalikulu mphamvu chomera chotenthetsera kutentha chubu khoma kutentha≤580℃superheater ndi chubu khoma kutentha & LT;540℃khoma nthunzi chitoliro ndi mutu, mtundu uwu wa zitsulo wakhala chimagwiritsidwa ntchito mu United States, Japan ndi Europe, ali ndi mbiri yakale ya ntchito mu zomera mphamvu, ndi ntchito khola, ndondomeko ntchito bwino zitsulo okhwima.

12Cr1MoV zitsulo ndi chromium-molybdenum vanadium zitsulo vanadium zitsulo, makamaka ntchito 12Cr1MoV/GB5310 chitoliro zitsulo. Chogwiritsidwa ntchito kwambiri, ndi kutentha kwa 480℃~ 580℃malo otentha kwambiri okhala ndi chimodzi mwazinthu zambiri. 12Cr1MoVG zitsulo chubu ntchito kutentha: izo makamaka ntchito zitsulo chachikulu cha chotenthetsera chubu, mutu ndi nthunzi chitoliro cha kukanika kukatentha kutentha amene chubu khoma kutentha ndi zosakwana kapena ofanana 580℃.

Njira yopangira:Kuyesa Kuuma:

1. Kugudubuza kotentha (chubu chachitsulo chosakanizidwa chotuluka) : chubu chozungulira → kutenthetsa → choboola → chopiringizira chopingasa katatu, kugudubuza mosalekeza → kuvula machubu → kukula (kapena kuchepetsa) → kuzirala → kuwongola → kuyesa kuthamanga kwamadzi (kapena kuzindikira kuti pali vuto ) → kuyika chizindikiro → kusungirako

2. Kujambula kozizira (kugudubuza) chubu chachitsulo chosasunthika: chubu chozungulira → chotenthetsera → choboola → mutu → kupukuta → pickling → kupaka mafuta (chophimba chamkuwa) → chojambula chozizira chambiri (kugudubuza kozizira) → chubu chopanda kanthu → chithandizo cha kutentha → kuwongola → madzi kuyesa kwamphamvu (kuzindikira zolakwika) → kuyika chizindikiro → kusungirako

Kulongedza:

Kulongedza mopanda kanthu / kulongedza mitolo / kulongedza ma crate / chitetezo chamatabwa mbali zonse ziwiri za machubu ndi kutetezedwa moyenera kuti atumizidwe moyenera panyanja kapena monga momwe akufunira.

Mwachidule

P92 muyezo wotentha kwambiri kutentha chubu wopanda aloyi chitoliro.

| Zokhazikika:Chithunzi cha ASTM A335 | Aloyi Kapena Ayi: Aloyi |

| Gulu la Gulu: P92 | Ntchito: Boiler Pipe |

| makulidwe: 1-100 mm | Chithandizo Chapamwamba: Monga Zofunikira za Makasitomala |

| Diameter Yakunja (Yozungulira): 10 - 1000 Mm | Katswiri: Wokulungidwa / Wozizira Wozizira |

| Utali: Utali Wokhazikika Kapena Utali Wachisawawa | Chithandizo cha kutentha: Annealing / Normalizing / Tempering |

| Maonekedwe a Gawo: Chozungulira | Chitoliro chapadera: Chitoliro Cholimba cha Khoma |

| Malo Ochokera: China | Kugwiritsa Ntchito: Kuthamanga Kwambiri Mpweya Wotentha, Boiler ndi Kusinthanitsa Kutentha |

| Chitsimikizo: ISO9001:2008 | Mayeso: ET/UT |

Chigawo cha Chemical

Mankhwala opangidwa ndi mipope yachitsulo yopanda msoko kuti aphwanye mafuta

| C | SI | Mn | P | S | Cr | Mo | |

| p92 | 0.07-0.13 | 0.5 | 0.30-0.60 | 0.02 | 0.01 | 8.50-9.5 | 0.30-0.60 |

Mechanical Property

| Katundu | Zambiri |

| Mphamvu zolimba, min, (MPa) | 620 Mpa |

| Mphamvu zokolola, min, (MPa) | 440Mpa |

Kutentha Chithandizo

|

Gulu | Mtundu wa Chithandizo cha Kutentha | Kutentha Kwambiri F [C] | Subcritical Annealing Kapena Kutentha |

| P5, P9, P11, ndi P22 | |||

| A335 P92 | Full Kapena Isothermal Anneal | ||

| Normalize And Temper | ***** | 1250[675] |

Kulekerera

Kwa Chitoliro Cholamulidwa Kuti Chikhale M'kati mwa Diameter, Diameter Yam'kati Siyenera Kusiyanasiyana Kuposa ± 1% Kuchokera M'kati Mwa Diameter Yotchulidwa.

Kusiyanasiyana Kovomerezeka Mu Diameter Yakunja

| Wopanga NPS | Kulekerera kwabwino | kulolerana koipa | ||

| In | Mm | In | Mm | |

| 1⁄8to 11⁄2, kuphatikiza | 1⁄64 (0.015) | 0.4 | 1⁄64(0.015) | 0.4 |

| Kupitilira 11⁄2 mpaka 4, kuphatikiza. | 1⁄32(0.031) | 0.79 | 1⁄32(0.031) | 0.79 |

| Kupitilira 4 mpaka 8, kuphatikiza | 1⁄16(0.062) | 1.59 | 1⁄32(0.031) | 0.79 |

| Kupitilira 8 mpaka 12, Inc. | 3⁄32(0.093) | 2.38 | 1⁄32(0.031) | 0.79 |

| Oposa 12 | ± 1% ya Zomwe Zatchulidwa | |||