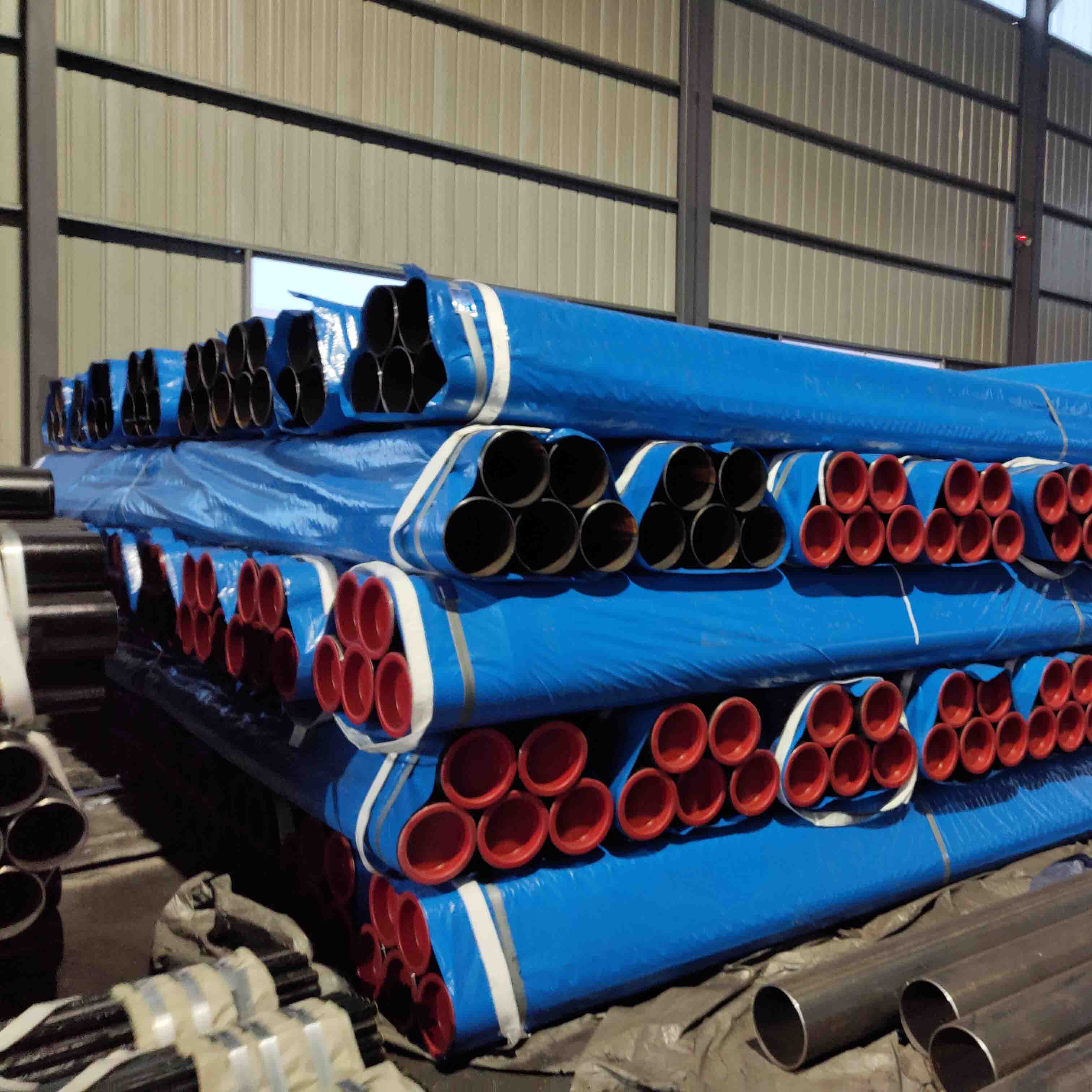

ASME SA-106/SA-106M-2015 Carbon simbi pombi

| Standard:ASTM SA106 | Alloy kana Kwete: Kwete |

| Giredhi Boka: G.A,GR.B,GR.C nezvimwe | Kushandisa: Fluid Pipe |

| Ukobvu: 1 - 100 mm | Surface Treatment: Sezvinodiwa nemutengi |

| Kunze Dyamita(Kutenderera): 10 - 1000 mm | Tekinoroji: Kupisa kwakatenderedzwa |

| Kureba: Hurefu hwakagadzika kana hurefu husina kurongeka | Kurapa kwekupisa: Annealing / normalizing |

| Chikamu Chimiro: Round | Special Pipe: Kupisa kwepamusoro |

| Nzvimbo Yekwakabva: China | Kushandiswa: Kuvaka, Fluid Transportation |

| Certification: ISO9001:2008 | Muedzo: ECT/CNV/NDT |

Seamless simbi pombi nokuda yakakwirira tembiricha kushandaASTM A106, yakakodzera kupisa kwakanyanya, Inoshandiswa zvakanyanya mupetroleum, indasitiri yemakemikari, bhaira, chiteshi chemagetsi, ngarava, kugadzira michina, mota, ndege, ndege, simba, geology, kuvaka uye indasitiri yemauto nemamwe maindasitiri.

Giredhi remhando yepamusoro kabhoni structural simbi: G.A,GR.B,GR.C

| Kuumbwa, % | |||

| Giredhi A | Giredhi B | Grade C | |

| Carbon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0.035 | 0.035 | 0.035 |

| Sulfur, max | 0.035 | 0.035 | 0.035 |

| Silicon, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Mhangura, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Pakudzikiswa kwega kwega kwe0.01% pazasi peiyo kabhoni yakataurwa, kuwedzera kwe0.06% manganese pamusoro peiyo yakataurwa kunobvumidzwa kusvika pachiyero che1.35%. | |||

| B Kunze kwekunge zvatsanangurwa neimwe nzira nemutengi, pakudzikisira kwega kwega kwe0.01% pazasi peiyo kabhoni yakanyanya kutaurwa, kuwedzera kwe0.06% manganese pamusoro peiyo yakanyanya kutaurwa ichabvumidzwa kusvika pachiyero che1.65%. | |||

| C Zvinhu zvishanu izvi zvasanganiswa hazvipfuuri 1%. | |||

| Giredhi A | Giredhi B | Grade C | ||||||

| Kusimba simba, min, psi(MPa) | 48 000(330) | 60 000(415) | 70 000(485) | |||||

| Goho simba, min, psi(MPa) | 30 000(205) | 35 000(240) | 40 000(275) | |||||

| Longitudinal | Transverse | Longitudinal | Transverse | Longitudinal | Transverse | |||

| Elongation mu2 in. (50 mm), min, % Basic elongation transverse strip bvunzo, uye kune ese madiki saizi akaedzwa muchikamu chizere | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Kana standard round 2-in. (50-mm) geji kureba bvunzo yemuenzaniso inoshandiswa | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Yekureba mitsetse miyedzo | A | A | A | |||||

| Yekuchinjika mitsetse bvunzo, kuderedzwa kune yega yega 1/32-in. (0.8-mm) kudzikira mukukora kwemadziro kuri pasi pe5/16 mukati. (7.9 mm) kubva pakurebesa zvishoma kwezvikamu zvinotevera zvichaitwa. | 1.25 | 1.00 | 1.00 | |||||

| A Hurefu hwakareba mu2 in. (50 mm) huchatemwa neinotevera equation: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| nokuda kwema-inch-pound units, uye | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| yezvikamu zveSI, | ||||||||

| kupi: e = elongation shoma mu2 in. (50 mm), %, yakatenderedzwa kusvika padyo 0.5%, A = mhiri-chikamu nharaunda yetension test specimen, in.2 (mm2), zvichibva pane yakatsanangurwa yekunze dhayamita kana zita rakatsanangurwa kunze kwedhayamita kana zita remuenzaniso upamhi uye kukora kwemadziro akataurwa, akatenderedzwa kusvika padyo 0.01 in.2 (1 mm2). (Kana iyo nzvimbo yakaverengerwa yakaenzana kana yakakura kupfuura 0.75 in.2 (500 mm2), ipapo kukosha 0.75 mu.2 (500 mm2) kuchashandiswa.), uye U = yakataurwa simba rekusimba, psi (MPa). | ||||||||

Pamusoro pekuve nechokwadi chekuumbwa kwemakemikari uye michina zvivakwa, hydrostatic bvunzo inoitwa imwe neimwe, uye flaring uye flattening bvunzo dzinoitwa. . Pamusoro pezvo, pane zvimwe zvinodikanwa zveiyo microstructure, saizi yezviyo, uye decarburization layer yepombi yesimbi yakapedzwa.

Kukwanisa Kugovera: 1000 Matani PaMwedzi Pagiredhi reASTM SA-106 Simbi Pipe

MuMasumbu Uye Mubhokisi Rakasimba Remapuranga

7-14 mazuva kana ari mustock, 30-45 mazuva ekugadzira

30% depsoit, 70% L/C kana B/L kopi kana 100% L/C pakuona