[Kopi] GB 3087 yakajairwa seamless bhaira alloy simbi pombi Yakaderera kudzvanywa Pakati pekumanikidza

Overview

Standard: GB/T3087-2008

Giredhi Boka: 10#,20#

Ukobvu: 1 - 100 mm

Kunze Dyamita(Kutenderera): 10 - 1000 mm

Kureba: Hurefu hwakagadzika kana hurefu husina kurongeka

Chikamu Chimiro: Round

Nzvimbo Yekwakabva: China

Certification: ISO9001:2008

Alloy Kana Kwete: isina musono kabhoni simbi

Kushandisa: Boiler Pipe

Surface Treatment: Sezvinodiwa nemutengi

Tekinoroji: Inopisa yakakungurutswa / inotonhora inodhonzwa

Kurapa kwekupisa: Normalizing

Special Pipe: Gobvu Wall Pipe

Kushandiswa: Kuvaka, Fluid Yekufambisa, Boiler uye Heat Exchanger

Muedzo: ET/UT

Application

Inonyanya kushandiswa kugadzira yakakwirira-mhando kabhoni dhizaini simbi, yakaderera kumanikidza yepakati kumanikidza boiler pombi, yakanyanya kupisa mutsi isina seamless kabhoni simbi pombi.

Main Grade

Giredhi remhando yepamusoro kabhoni yekugadzira simbi: 10#,20#

Chemical Component

| Standard | Giredhi | Muumbi weKemikari(%) | |||||||

| C | Si | Mn | P | S | Cr | Cu | Ni | ||

| GB3087 | 10 | 0.07~0.13 | 0.17 ~ 0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3 ~ 0.65 | ≤0.25 | ≤0.30 |

| 20 | 0.17–0.23 | 0.17 ~ 0.37 | 0.38~0.65 | ≤0.030 | ≤0.030 | 0.3 ~ 0.65 | ≤0.25 | ≤0.30 | |

Mechanical Property

| Standard | Simbi pombi | Kukora kwemadziro | Kusimba simba | Goho Simba | Elongation |

| GB3087 | (mm) | (MPa) | (MPa) | % | |

| ≥ | |||||

| 10 | / | 335~475 | 195 | 24 | |

| 20 | <15 | 410~550 | 245 | 20 | |

| ≥15 | 225 | ||||

Kushivirira

Kutsauka kunobvumirwa kwekunze kwekunze kwemachubhu esimbi

| Rudzi rwesimbi chubhu | Kutsauka kunobvumirwa | ||||||

| Inopisa yakakungurutswa (yakawedzera, yakawedzera) chubhu yesimbi | ± 1.0% D kana ± 0.50, tora nhamba huru | ||||||

| Cold drawn (yakakunguruka) chubhu yesimbi | ± 1.0% D kana ± 0.30, tora nhamba huru | ||||||

Kutsauka kunobvumidzwa kwemadziro emadziro ekupisa akakungurutswa (extrusion, kuwedzera) simbi machubhu.

Chikamu: mm

| Rudzi rwesimbi chubhu | Kunze kwekunze kwesimbi chubhu | S / D | Kutsauka kunobvumirwa | ||||||

| inopisa yakakungurutswa (extruded) simbi chubhu | ≤ 102 | - | ± 12.5 % S kana ± 0.40, tora nhamba huru | ||||||

| > 102 | ≤ 0.05 | ± 15% S kana ± 0.40, tora nhamba huru | |||||||

| > 0.05 ~ 0.10 | ± 12.5% S kana ± 0.40, tora nhamba huru | ||||||||

| > 0.10 | + 12.5% S | ||||||||

| - 10% S | |||||||||

| inopisa kuwedzera simbi chubhu | + 15% S | ||||||||

Kutsauka kunobvumirwa kwemadziro emadziro echando chakadhonzwa (akakungurutswa) machubhu esimbi

Chikamu: mm

| Rudzi rwesimbi chubhu | Kukora kwemadziro | Kutsauka kunobvumirwa | ||||||

| Cold drawn (yakakunguruka) chubhu yesimbi | ≤ 3 | 15 - 10 % S kana ± 0.15, tora nhamba huru | ||||||

| > 3 | + 12.5% S | |||||||

| - 10% S | ||||||||

Test Chinodiwa

Flattening bvunzo

Machubhu esimbi ane dhayamita rekunze rakakura kupfuura 22 mm uye anosvika 400 mm, uye ukobvu hwemadziro hwakakura kupfuura 10 mm hunofanirwa kuita bvunzo yekubata kumeso. Mushure mokunge sampuli dzakapetwa

Bending test

Machubhu esimbi ane dhayamita rekunze risingapfuuri 22 mm anofanira kupinda muyedzo yekukotama. Kona yekukombama i90o . Radhiyasi yekupeta ndeye 6 nguva yekunze dhayamita yechubhu yesimbi.Mushure mekupeta sampuli, hapana kutsemuka kana kutsemuka kunobvumidzwa kuoneka pamuenzaniso.

Macroscopic kuongorora

Kune machubhu esimbi anogadzirwa zvakananga nekuramba akakanda mabheti kana ingots dzesimbi, bato rinopa rinofanirwa kuvimbisa kuti hapana mavara machena, tsvina, pasi-pamusoro pemhepo mabhuru, zvigamba zvedehenya kana kuiswa pamuchinjiko-chikamu asidhi yakasanganiswa macroscopic tissue yebillet kana. simbi chubhu.

Kuongorora kusina kuparadza

Zvinoenderana nechikumbiro chebato ririkuda, izvo zvinozotaurirana pakati pevanopa nevanoda mapato uye zvichiratidzwa muchibvumirano, kutariswa kwehupenzi hwe ultrasonic kunogona kuitwa yega kune machubhu esimbi. Iyo longitudinal manual defect yereferensi sampuli chubhu inofanirwa kusangana nezvinodiwa zvemashure-yekuongorora yekugamuchira giredhi C8 inotsanangurwa muGB/T 5777-1996.

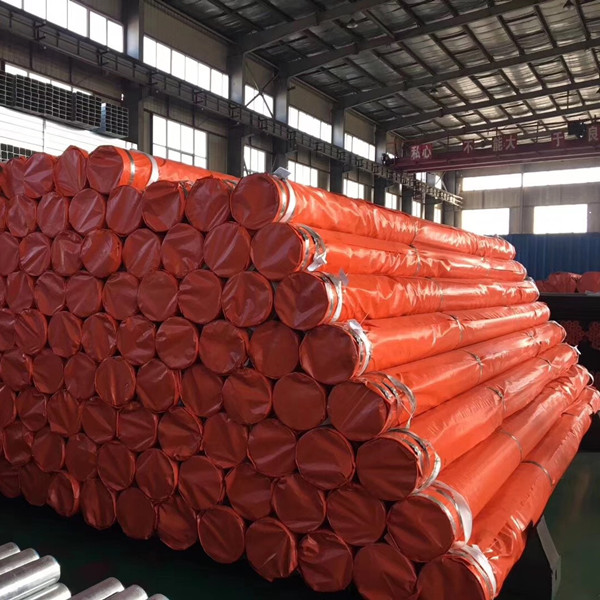

![[Kopi] GB 3087 yakajairwa seamless bhaira alloy simbi pombi Yakaderera kudzvanywa Kwepakati kumanikidzwa Featured Image](http://www.sanonpipe.com/uploads/94fbbe30.jpg)

![[Kopi] GB 3087 yakajairwa seamless bhaira alloy simbi pombi Yakaderera kudzvanywa Pakati pekumanikidza](http://www.sanonpipe.com/uploads/94fbbe30-300x300.jpg)

![[Kopi] GB 3087 yakajairwa seamless bhaira alloy simbi pombi Yakaderera kudzvanywa Pakati pekumanikidza](http://www.sanonpipe.com/uploads/511177b11-300x300.png)

![[Kopi] GB 3087 yakajairwa seamless bhaira alloy simbi pombi Yakaderera kudzvanywa Pakati pekumanikidza](http://www.sanonpipe.com/uploads/dd7d856f-300x300.jpg)