Galvanized Steel Pipe

Kambani yedu inoita seamless simbi pombi ekisipotigalvanized pipe, Seamless Galvanized Pipe, SMLS galvanized pombi, WEDED galvanized pipe.

Ndeupi musiyano uripo pakati pekupisa galvaninzed nechando galvanized?

Kupisa-dip galvanizing uye kutonhora kwakakurudzira musiyano:

1. Galvanizing, inozivikanwawo seanopisa dip yakakurudzira, ndiye ingot yakanyungudutswa pakupisa kwepamusoro, nhamba yezvinyorwa zvekuwedzera panzvimbo, zvino yakanyikwa marata ekugadzirwa kwesimbi, chikamu chesimbi pamucheka we zingi. Zvakanakira zvekupisa-dip galvanizing corrosion yekugona kwake, kunamatira uye kuoma kwe zinc coating zviri nani.

"Cold plated" kana "plating", kureva kuti zinc munyu solution ne electrolysis, kusvika pakuputira pamusoro pekuputira, kazhinji haina kudziyisa, shoma shoma ye zinc, nzvimbo yakanyorova iri nyore kudonha.

2. Dip inopisa yakabatiswa (galvanizing)

Kupisa-dip galvanizing kurapwa kwemakemikari, ndiyo electrochemical reaction.

Cold galvanizing ndiyo kero yemuviri, ingo bhurasha nzvimbo ye zinc, iyo zinc layer iri nyore kudonha. Kuvaka mukushandiswa kwekupisa dip galvanizing.

Inoenderera ichipisa dip galvanizing process: simbi → kudziyisa → kutonhora kusvika kune tembiricha yakabatiswa marata → kutonhora →

Cold galvanized zinc ingori 10-50g/m2, yayo pachayo corrosion resistance pane kupisa dip galvanized a lot of difference. Yakavharidzirwa nemutengo wakaderera.

Kupisa dip galvanized simbi muviri inopisa dip galvanized surface pasi pemamiriro ekunamatira kwayo kwakasimba, haisi nyore kudonha, kunyangwe paine dip inopisa.galvanized pipecorrosion phenomenon, asi munguva yakareba kwazvo yekusangana nehunyanzvi, hutano zvinodiwa.

3. Misiyano yehunyanzvi

Chekutanga, ndiwo musiyano uripo pakati pemaitiro: inopisa-dip galvanizing ndiyo workpiece degreasing, pickling, dipping, kuomesa mvura kunyudzwa mune yakanyungudutswa zinc imwe nguva yenguva, inogona kusimudzwa.

Iyo inozivikanwawo se electro-galvanized cold galvanizing, ndeye kushandisa electrolysis zvishandiso basa chidimbu kuburikidza ne degreasing, pickling ingredients post kupinda zinc munyu mhinduro, uye batanidza anode electrolysis midziyo; panzvimbo pamativi e zinc plate yakabatana ne electrolysis midziyo yakanaka, simba pa, kushandiswa kwezvino kubva pa cathode kusvika kune anode yekutungamira mafambiro eiyo workpiece ichaiswa muchikamu chezingi.

Zinc yakapedza mutsauko: hapana inotonhora yakanyungudutswa inopisa-dip galvanizing yakapfava inopenya kutaridzika, asi ukobvu hwezinc yekuputira yeinotonhora inonamira zvinhu zvekupisa-dip galvanizing kakati wandei. Galvanized corrosion resistance iri zvakare kakawanda.

Overview

Application

Iyo Inonyanya Kushandiswa kune simba uye kumanikidza zvikamu, uye kune zvakajairika chinangwa chiputi, mvura, gasi uye mhepo pombi.

Main Grade

G.A, GR.B

Chemical Component

| Giredhi | Chikamu %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| S rudzi (seamless pombi) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| E mhando (Resistance welded pombi) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| F mhando (Furnace Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Huwandu hwezvinhu zvishanu izvi haifanire kunge yakakura kupfuura 1.00%.

B Kune yega yega 0.01% inoderera mune yakanyanya kabhoni yemukati, iyo yakanyanya manganese yemukati inobvumirwa kuwedzera ne0.06%, asi iyo yakawanda haigoni kudarika 1.35%.

C Imwe neimwe 0.01% inodzikira mune yakanyanya kabhoni yemukati inobvumira iyo yakanyanya manganese yemukati kuti iwedzere ne0.06%, asi iyo yakawanda haifanire kudarika 1.65%.

Mechanical Property

| chinhu | G.A | GR.B |

| kusimba simba, ≥, psi [MPa] Goho Simba, ≥, psi [MPa] Gauge 2in. kana 50mm kureba | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Hurefu hudiki hwegeji 2in. (50mm) ichatemwa neinotevera fomula:

e=625000(1940)A0.2/U0.9

e = iyo shoma kureba kwegeji 2in. (50mm), iyo muzana yakatenderedzwa kune iri pedyo 0.5%;

A = Yakaverengerwa zvinoenderana neyakatsanangurwa yekunze dhayamita yezita rechubhu kana hupamhi hwezita reiyo tensile sampu uye yakatsanangurwa iyo madziro ukobvu, uye yakatenderedzwa kune iri padyo muchinjiko-chikamu nharaunda yetensile sampu ye0.01 in.2 (1 mm2), uye Inofananidzwa ne0.75in.2 (500mm2), chero idiki.

U = yakataurwa shoma shoma simba, psi (MPa).

B Nekusanganiswa kwakasiyana-siyana kwehukuru hwakasiyana hwematanho ekuedza uye akatemerwa kushomeka kwekusimba kwesimba, iyo shoma inodiwa elongation inoratidzwa muTebhu X4.1 kana Tafura X4.2, zvichienderana nekushanda kwayo.

Test Chinodiwa

Tensile bvunzo, kukotama bvunzo, hydrostatic bvunzo, nondestructive magetsi bvunzo yewelds.

Supply Ability

Kugona Kugovera: 2000 Matani PaMwedzi Pagiredhi reASTM A53/A53M-2012 Pipe yeSimbi

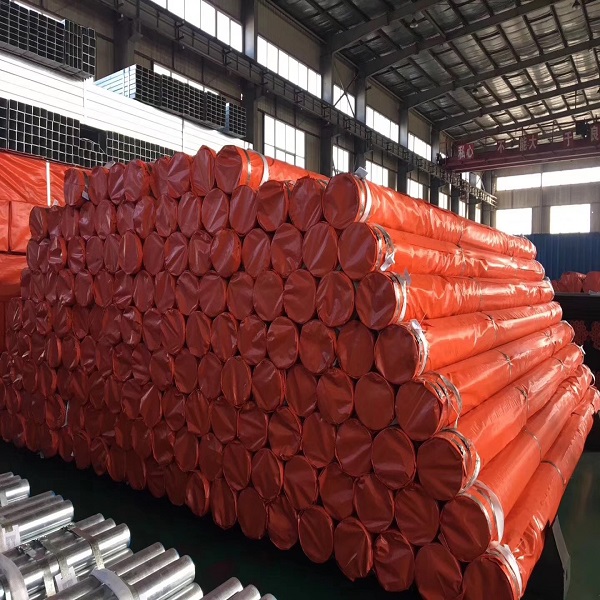

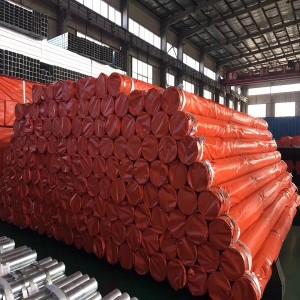

Packaging

MuMasumbu Uye Mubhokisi Rakasimba Remapuranga

Delivery

7-14 mazuva kana ari mustock, 30-45 mazuva ekugadzira

Payment

30% depsoit, 70% L/C kana B/L kopi kana 100% L/C pakuona