1. Nhanganyaya kupombi yesimbi isina musono

Seamless simbi pombi ipombi yesimbi ine hollow cross-section uye isina seam dzakaitenderedza. Iine simba guru, corrosion resistance uye yakanaka thermal conductivity. Nekuda kwekuita kwayo kwakanaka, mapaipi esimbi asina musono anoshandiswa zvakanyanya munzvimbo dzakasiyana dzakadai sepeturu, indasitiri yemakemikari, simba remagetsi, uyekuvaka.

2. Seamless simbi pombi kugadzira muitiro

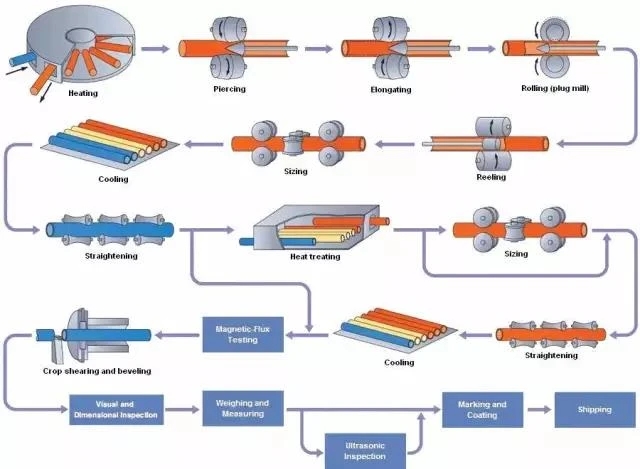

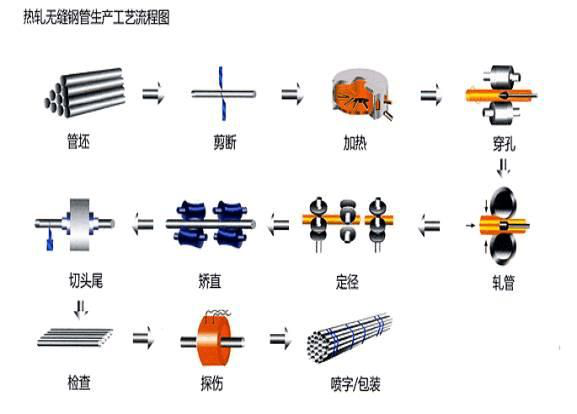

Iyo nzira yekugadzira isina musono simbi pombi inonyanya kusanganisira anotevera matanho:

a. Gadzirira zvigadzirwa: Sarudza mabheti esimbi akakodzera, anoda nzvimbo yakatsetseka, isina mabubble, isina kutsemuka, uye isina hurema huri pachena.

b. Kupisa: Kupisa billet yesimbi kusvika pakupisa kwepamusoro kuti iite plastiki uye nyore kugadzira.

c. Perforation: Iyo inopisa simbi billet inoputirwa muchubhu isina chinhu kuburikidza nemuchina wekuboora, kureva, yekutanga yakagadzirwa simbi pombi.

d. Pipe rolling: Iyo chubhu isina chinhu inokungurutswa kakawanda kuti ideredze dhayamita, kuwedzera kukora kwemadziro ayo, uye kubvisa kushushikana kwemukati.

e. Kukura: Iyo pombi yesimbi inozopedzisira yaumbwa kuburikidza nemuchina wekuyera kuitira kuti dhayamita uye kukora kwemadziro kwepombi yesimbi kuzadzisa zvinodiwa.

f. Kutonhodza: Iyo pombi yesimbi yakaumbwa yakatonhodzwa kuti iwedzere kuoma kwayo uye simba.

g. Kutwasanudza: ruramisa pombi yesimbi yakatonhodzwa kubvisa deformation yayo.

h. Kuongorora kwemhando: Ita ongororo yemhando papombi dzesimbi dzakapedzwa, kusanganisira kuongorora ukuru, ukobvu hwemadziro, kuoma, kunaka kwepasi, nezvimwe.

3. Iyo yekugadzira nzira yesimbi isina musono pombi#Seamless Simbi Pipe#

3. Iyo yekugadzira nzira yesimbi isina musono pombi#Seamless Simbi Pipe#

Iyo chaiyo maitiro ekugadzira seamless simbi mapaipi ndeaya anotevera:

a. Gadzirira zvigadzirwa: Sarudza mabhii esimbi akakodzera, asingade kukanganisa, asina mabhuru, uye asina makatsemuka pamusoro.

b. Kupisa: Kupisa simbi billet kune yakakwira tembiricha mamiriro, yakajairika kupisa tembiricha ndeye 1000-1200 ℃.

c. Perforation: Iyo inopisa simbi billet inoputirwa muchubhu isina chinhu kuburikidza nemuchina wekuboora. Panguva ino, iyo tube blank haisati yanyatsoumbwa.

d. Pipe rolling: Iyo chubhu isina chinhu inotumirwa kumuchina wekutenderedza pombi kune akawanda rollings kuderedza dhayamita yechubhu uye kuwedzera kukora kwemadziro, uku uchibvisa kushushikana kwemukati.

e. Reheating: Reheat the rolled chubhu isina kuvharwa kuti ubvise kushushikana kwayo kwemukati.

f. Kukura: Iyo pombi yesimbi inozopedzisira yaumbwa kuburikidza nemuchina wekuyera kuitira kuti dhayamita uye kukora kwemadziro kwepombi yesimbi kuzadzisa zvinodiwa.

g. Kutonhodza: Pedzisa pombi yesimbi yakaumbwa, kazhinji uchishandisa kutonhora kwemvura kana kutonhodza mhepo.

h. Kutwasanudza: ruramisa pombi yesimbi yakatonhodzwa kubvisa deformation yayo.

i. Kuongorora kwemhando: Ita ongororo yemhando papombi dzesimbi dzakapedzwa, kusanganisira kuongorora ukuru, ukobvu hwemadziro, kuoma, kunaka kwepasi, nezvimwe.

Munguva yekugadzirwa kwezvinhu, zvinotevera zvinoda kuonekwa: kutanga, hutano uye kugadzikana kwezvinhu zvakasvibirira zvinofanira kuvimbiswa; chechipiri, tembiricha uye kumanikidzwa kunofanira kunyatsodzorwa panguva yekuboora uye kukunguruka maitiro kudzivirira kutsemuka uye deformation; pakupedzisira, saizi uye kutonhora Kugadzikana uye kutwasuka kwepombi yesimbi kunofanirwa kuchengetedzwa panguva yekuita.

4. Kudzora kwehutano hwepombi dzesimbi dzisina musono

Kuti uve nechokwadi chemhando yepombi dzesimbi isina musono, zvinotevera zvinofanirwa kudzorwa:

a. Raw materials: Shandisa simbi dzemhando yepamusoro kuona kuti hapana chakakanganisika, mabubbles, kana makatsemuka pamusoro. Panguva imwecheteyo, zvinodikanwa kuve nechokwadi chekuti makemikari ekuumbwa uye mechanical zvivakwa zvezvakagadzirwa zvinhu zvinosangana zvakajairwa zvinodiwa.

b. Maitiro ekugadzira: Nyatsodzora maitiro ega ega mukuita kwekugadzira kuti uve nechokwadi chekuti mhando yega yega yakagadzikana uye yakavimbika. Kunyanya panguva yekuboora nekukunguruka maitiro, tembiricha uye kudzvanywa kunofanirwa kudzorwa zvakanyanya kudzivirira kutsemuka uye deformation.

c. Dimensional: Ita ongororo yedimensional papombi dzesimbi dzakapedzwa kuona kuti dhayamita radzo uye ukobvu hwemadziro zvinosangana nezvinodiwa. Zvishandiso zvekuyeresa zvakakosha zvinogona kushandiswa kuyera, senge micrometers, madziro makubvu ekuyeresa zviridzwa, nezvimwe.

d. Unhu hwepamusoro: Ita ongororo yemhando yepamusoro pamapombi esimbi akapedzwa, kusanganisira kushata kwepamusoro, kuvapo kwekutsemuka, kupeta uye kumwe kukanganisa. Kuonekwa kunogona kuitwa uchishandisa ongororo yekuona kana hunyanzvi hwekuyedza zviridzwa.

e. Metallographic chimiro: Ita metallographic chimiro bvunzo pane yakapedzwa simbi pombi kuti ive nechokwadi chekuti metallographic chimiro chinosangana nezvinodiwa. Kazhinji, maikorosikopu inoshandiswa kuona iyo metallographic chimiro uye kutarisa kana paine microscopic kuremara.

f. Mechanical properties: Mechanical properties yemapombi esimbi akapedzwa anoedzwa, anosanganisira kuoma, kusimba kwesimba, kusimba kwegoho uye zvimwe zviratidzo. Tensile yekuyedza michina nemimwe michina inogona kushandiswa pakuyedza.

Kuburikidza nematanho epamusoro ekudzora emhando yepamusoro, mhando yepombi dzesimbi dzisina musono dzinogona kuve dzakagadzika uye dzakavimbika, dzichisangana nezvinodiwa zveminda dzakasiyana dzekushandisa.

5. Nzvimbo dzekushandisa dzepombi dzesimbi dzisina musono

Mapaipi esimbi asina musono ane huwandu hwakawanda hwekushandisa, kunyanya kusanganisira zvinotevera zvinhu:

a. Indasitiri yePetroleum: inoshandiswa mumapombi ematsime emafuta, mapaipi emafuta uye mapaipi emakemikari muindasitiri yepetroleum. Mapombi esimbi asina musono ane hunhu hwekusimba kwepamusoro, corrosion resistance, uye yakakwirira tembiricha kuramba, uye inogona kuve nechokwadi chekuchengetedza uye kugadzikana kushanda kweindasitiri yepetroleum.

b. Indasitiri yemakemikari: Muindasitiri yemakemikari, mapaipi esimbi asina musono anoshandiswa zvakanyanya mumapaipi akasiyana-siyana emakemikari anoita, mapaipi ekufambisa emvura, nezvimwewo Nekuda kwekushomeka kwayo kwakasimba, inogona kuramba kukukurwa kwezvinhu zvakasiyana-siyana zvemakemikari, kuve nechokwadi chekuchengetedzwa kwekugadzirwa uye kushanda zvakanaka kweindasitiri yemakemikari.

Seamless simbi pombi isimbi yakatenderera ine mhango chikamu uye isina misono yakaitenderedza. Iine hunhu hwekusimba kwepamusoro, corrosion resistance, tembiricha yepamusoro uye kushomeka kwekushisa. Zvinoenderana neakasiyana maitiro ekugadzira, mapaipi esimbi asina musono anogona kukamurwa kuva marudzi maviri: hot-yakakungurutswa mapaipi uye inotonhora-yakakungurutswa pombi. Mapaipi anopisa anogadzirwa nekudziisa simbi mabheti pakupisa kwepamusoro kweperforation, rolling, kutonhora uye mamwe maitiro, uye akakodzera kune yakakura uye yakaoma cross-section simbi mapaipi; mapaipi anotonhora anokungurutswa anokungurutswa patembiricha yekamuri uye akakodzera kugadzirwa Diki-chikamu-chikamu uye yakakwirira nemazvo esimbi pombi.

Nguva yekutumira: Nov-28-2023