15Mo3 (15MoG): Ipombi yesimbi muDIN17175 chiyero. Iyo idiki dhayamita kabhoni molybdenum simbi chubhu ye boiler uye superheater, uye pearlescent mhando inopisa simba simbi. Muna 1995, yakasimwa kuneGB5310uye yakanzi 15MoG. Mushonga wayo wemakemikari uri nyore, asi une molybdenum, saka une simba rinopisa riri nani pane kabhoni simbi uku uchichengeta maitiro akafanana nekabhoni simbi. Nekuda kwekuita kwayo kwakanaka, mutengo wakachipa, wakashandiswa zvakanyanya munyika. Zvisinei, simbi ine tsika ye graphitization mushure mekushanda kwenguva refu pakupisa kwepamusoro, saka kupisa kwayo kwekushanda kunofanira kudzorwa pasi pe510 ℃, uye huwandu hweAl hunowedzerwa mukunyunguduka hunofanira kugumira kudzora uye kunonoka graphitization process. Iyi chubhu yesimbi inonyanya kushandiswa kune yakaderera tembiricha superheater uye yakaderera tembiricha reheater. Tembiricha yemadziro iri pasi pe510 ℃. Mushonga wayo wemakemikari C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Yakajairika simba nhanho σs≥270-285, σb≥450-600 MPa; Plastic delta 22 kana kupfuura.

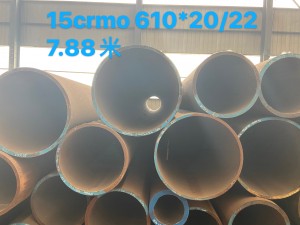

15CrMoG:GB5310-95 simbi (inoenderana ne1CR-1 / 2Mo uye 11 / 4CR-1 / 2MO-Si simbi inoshandiswa zvakanyanya munyika), chromium yayo yakakwira kupfuura 12CrMo simbi, saka ine yakakwirira yekupisa simba pa500-550 ℃. Kana tembiricha yadarika 550 ℃, simba rekupisa resimbi rinodzikira zvakanyanya. Kana ikashandiswa kwenguva yakareba pa500-550 ℃, graphitization haiitike, asi carbide spheroidization uye alloying element redistribution inoitika, izvo zvinotungamira mukudzikira kwesimba rekupisa kwesimbi. Simbi ine yakanaka kuramba kuzorora pa450 ℃. Kugadzira kwayo pombi uye welding process performance yakanaka. Inonyanya kushandiswa seyakakwirira uye yepakati kumanikidza chipfunga chemukoto uye kubatanidza bhokisi rine chiutsi parameter pazasi 550 ℃, superheater chubhu ine mudhuri tembiricha pazasi 560 ℃, etc. Its kemikari inoumbwa C0.12-0.18, Si0.17-0.37, MN0.40-0.70, S≤0.030, P. CR0.80-1.10, MO0.40-0.55; Pasi pemamiriro akajairika ekupisa, chiyero chesimba σs≥235, σb≥440-640 MPa; Plastic Delta p21.

T22 (P22), 12Cr2MoG: T22 (P22) variASME SA213 (SA335) kodhi zvinhu, izvo zvinosanganisirwa mukatiGB5310-95. MuCR-Mo simbi yakatevedzana, kushanda kwayo kwesimba rekupisa kwakawedzera, tembiricha yakafanana yakasimba yakasimba simba uye inotenderwa kushushikana kupfuura 9CR-1Mo simbi kunyange yakakwirira, saka inoshandiswa zvakanyanya mukunze kwesimba rekupisa, simba renyukireya uye midziyo yekumanikidza. Nekudaro, hupfumi hwayo hwehunyanzvi hwakaderera kune yedu 12Cr1MoV, saka haishandiswe mudzimba yekupisa magetsi boiler kugadzira. Shandisa chete kana zvichidikanwa (kunyanya kana wakagadzirwa uye uchigadzirwa zvinoenderana neASME kodhi). Iyo simbi hainzwe kupisa kurapwa uye ine yakakwirira yakasimba yepurasitiki uye yakanaka welding performance. T22 diki dhayamita chubhu inonyanya kushandiswa sesimbi madziro tembiricha pazasi 580 ℃ superheater uye reheater kudziyisa pamusoro pemvura chubhu, nezvimwewo,P22hombe dhayamita chubhu inonyanya kushandiswa musimbi yemadziro tembiricha haina kupfuura 565 ℃ superheater / reheater coupling bhokisi uye hombe pombi pombi. Mushonga wayo wemakemikari C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; Pasi pemamiriro akajairika ekupisa, chiyero chesimba σs≥280, σb≥450-600 MPa; Plastiki delta 20 kana kupfuura.

12Cr1MoVG:GB5310-95 nano yakajairwa simbi, ndiyo yepamba yakakwira kudzvanywa, yakanyanya kudzvanywa, subcritical power plant boiler superheater, bhokisi rekuunganidza uye main steam conduit inoshandiswa zvakanyanya simbi. Iyo kemikari kuumbwa uye michina zvimiro zve 12Cr1MoV ndiro zvakangofanana. Kuumbwa kwayo kwemakemikari kuri nyore, iyo yakazara alloy yemukati iri pasi pe2%, kune yakaderera kabhoni, yakaderera alloy pearlescent mhando yesimbi inopisa simba. Vanadium inogona kuumba yakagadzika carbide VC ine kabhoni, iyo inogona kuita chromium uye molybdenum musimbi zviri nani kuvepo mune ferrite, uye inonoke kuchinjisa mwero wechromium uye molybdenum kubva kune ferrite kuenda kucarbide, kuitira kuti simbi igadzikane pakupisa kwakanyanya. Huwandu hwezvinhu zvakasanganiswa musimbi iyi ihafu chete ye2.25 CR-1Mo simbi inoshandiswa zvakanyanya kunze kwenyika, asi iyo yakasimba simba pa580 ℃ uye 100,000 h ndeye 40% yakakwirira kupfuura iyo yekupedzisira. Uyezve, maitiro ekugadzira ari nyore uye kuita kwewelding kwakanaka. Chero bedzi nzira yekurapa yekupisa yakasimba, kushanda kwakazara uye kushanda kwesimba rekupisa kunogona kugutsikana. Kushanda chaiko kwechiteshi chemagetsi kunoratidza kuti pombi huru ye12Cr1MoV inogona kushandiswa mushure mekushanda kwakachengeteka pa540 ℃ kwemaawa 100,000. Iyo hombe-dhayamita chubhu inonyanya kushandiswa sebhokisi rekuunganidza uye main steam conduit yemhepo inopfungaira pazasi 565 ℃, uye diki-diameter chubhu inoshandiswa kune boiler yekudziya pamusoro pehubhu yesimbi yemadziro tembiricha pazasi 580 ℃.

12Cr2MoWVTiB (G102) :Gb5310-95 musimbi, yekuvandudza kweChina mu1960s, yakaderera kabhoni, yakaderera alloy (diki diki siyana) Bainite mhando inopisa simba simbi, kubva kuma1970 yaisanganisirwa muBazi reMetallurgical Indasitiri chiyero YB529-70 uye ikozvino chiyero chenyika, pakupera kwa1980 iyo simbi yeMichina yeMichina yeMichina uye Metal Electro. kubatana chiziviso. Simbi ine yakanaka comprehensive mechanical properties, uye simba rayo rinopisa uye tembiricha yebasa yakakwira kupfuura iya yesimbi dzakafanana kunze kwenyika, inosvika pamwero weimwe chromium-nickel austenitic steels pa620℃. Izvi zvinodaro nekuti simbi ine akawanda marudzi ealloying zvinhu, uye zvakare yakawedzerwa kuvandudza oxidation kuramba kwezvinhu zvakaita seCr, Si, saka tembiricha yepamusoro sevhisi inogona kusvika 620 ℃. Kushanda chaiko kwechiteshi chemagetsi kunoratidza kuti chimiro uye zvinhu zvepombi yesimbi hazvichinje zvakanyanya mushure mekushanda kwenguva refu. Iyo inonyanya kushandiswa senge superheater chubhu uye reheater chubhu kune yekupedzisira-yakakwira paramende bhaira ine tembiricha yesimbi ≤620 ℃. Kemikari yayo C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42, 0.05-0. B0.002-0.008; Pasi pemamiriro akajairika ekupisa, chiyero chesimba σs≥345, σb≥540-735 MPa; Plastic Delta p18.

Sa-213t91 (335P91): Nhamba yesimbi mukatiASME SA-213(335) mwero. Inogadzirwa neRubber Ridge National Laboratory yeUnited States of America, inoshandiswa musimba renyukireya (inogonawo kushandiswa mune zvimwe zvinhu) yakakwirira tembiricha yekutsikirira zvikamu zvechinhu, simbi yakavakirwa paT9 (9CR-1MO) simbi, mumuganhu weiyo kabhoni yemukati, yakanyatso kudzora zvirimo zveP uye S uye zvimwe zvakasara zvinhu panguva imwe chete, Imwe mhando nyowani yesimbi yakaumbwa nekuwedzera kupisa kwesimbi. 0.030-0.070% N, 0.18-0.25% V uye 0.06-0.10% Nb kusangana nezvinodiwa zvekugadzirisa zviyo. ZviriASME SA-213column standard steel, iyo yakasimwa mukatiGB5310chiyero muna 1995 uye giredhi iri 10Cr9Mo1VNb. Iyo yepasi rose mwero ISO/ DIS9399-2 yakanyorwa se X10 CRMOVNB9-1.

Nekuda kweiyo yakakwira chromium yemukati (9%), yayo oxidation kuramba, corrosion resistance, kusimba kwekushisa kwepamusoro uye kwete-graphitization maitiro ari nani pane ayo epasi alloy simbi. Molybdenum (1%) inonyanya kunatsiridza tembiricha yakasimba uye inhibits iyo inopisa embrittling tsika yechromium simbi. Kuenzaniswa neT9, iyo welding uye yekupisa kuneta zvinhu inovandudzwa, iyo yakasimba simba pa600 ℃ yakapetwa katatu pane yekupedzisira, uye yakanakisa-yepamusoro-tembiricha yekudzivirira ngura yeT9 (9CR-1Mo) simbi inochengetwa. Kana ichienzaniswa neaustenitic stainless simbi, iyo coefficient yekuwedzera idiki, thermal conductivity yakanaka, uye ine yakasimba yakasimba yakasimba (senge neTP304 austenitic steel ratio, kusvika tembiricha yakasimba i625 ℃, tembiricha yekushushikana yakaenzana i607 ℃). Naizvozvo, ine zvirinani zvakakwana zvemichina zvivakwa, yakagadzikana chimiro uye zvivakwa pamberi uye mushure mekuchembera, yakanaka welding uye process zvivakwa, yakakwirira yakasimba yakasimba uye oxidation kuramba. Iyo inonyanya kushandiswa kune superheater uye reheater nesimbi tembiricha ≤650 ℃ mu boiler. Kemikari yaro yemakemikari C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, Al≤0.010 N0. N0.03-0.07; Pasi pemamiriro akajairika ekupisa, chiyero chesimba σs≥415, σb≥585 MPa; Plastiki delta 20 kana kupfuura.

Nguva yekutumira: Sep-07-2022