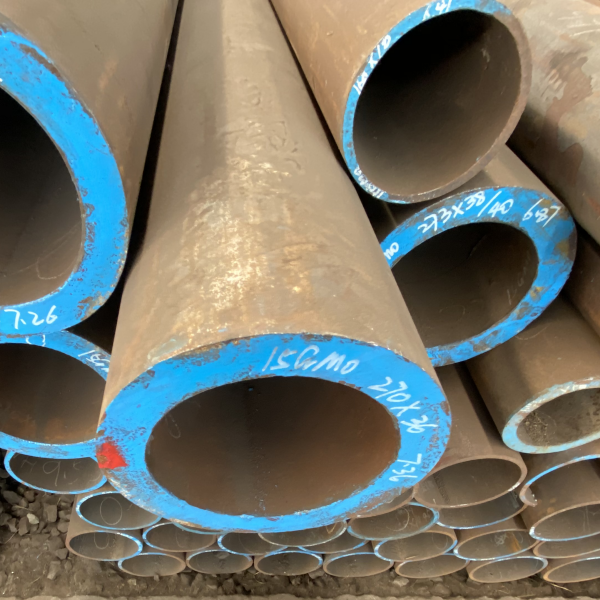

Seamless Simbi Machubhu ePetroleum Cracking, GB9948-2006, Sanon Pipe

| Standard: GB9948-2006 | Kurapa Kupisa: Annealing/normalizing/Tempering |

| Giredhi Boka: 10, 12CrMo, 15CrMo, 07Crl9Nil0, nezvimwe | Kunze Diameter(Kutenderera): 10 - 1000 Mm |

| Ukobvu: 1 - 100 mm | Kushandisa: kupisa kupisa machubhu |

| Kunze Dyamita(Kutenderera): 10 - 1000 mm | Kurapa Kwepamusoro: Sezvinodiwa neMutengi |

| Kureba: Hurefu hwakagadzika kana hurefu husina kurongeka | Tekinoroji: Kupisa kwakatenderedzwa |

| Chikamu Chimiro: Round | Special Pipe: Gobvu Wall Pipe |

| Nzvimbo Yekwakabva: China | Kushandiswa: kupisa kupisa machubhu |

| Certification: ISO9001:2008 | Muedzo:UT/MT |

Machubhu esimbi asina musono ekutsemuka peturu anoshanda kumachubhu esimbi asina musono emachubhu echoto, machubhu ekutsinhana kupisa uye pombi dzekumanikidza muindasitiri yepetrochemical.

High quality carbon structural simbi mamakisi ari 20g, 20mng uye 25mng.

Alloy zvimiro zvesimbi mamakisi: 15mog, 20mog, 12crmog

15CrMoG, 12Cr2MoG, 12CrMoVG, nezvimwe

Giredhi remhando yepamusoro kabhoni structural simbi: 10 #,20#

High quality carbon structural simbi mamakisi: 20g, 20mng uye 25mng

Alloy zvimiro zvesimbi mamakisi: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, nezvimwewo.

| No | Giredhi | Chemical Component % | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Yemhando yepamusoro Carbon Structural Steel | 10 | 0. 07-0.13 | 0.17 -0. 37 | 0.35 -0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 |

| 20 | 0.17-0. 23 | 0.17 -0. 37 | 0.35 -0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0. 025 | 0. 015 | |

| Alloy Structural Steel | 12CrMo | 0. 08-0.15 | 0.17 -0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 |

| 15CrMo | 0.12 -0.18 | 0.17-0. 37 | 0.40 -0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50 -1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45 -0.65 | <0. 30 | - | - | - | <0, 20 | 0. 025 | 0. 015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15 -0. 30 | <0. 20 | 0.025 | 0. 010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0. 025 | 0. 015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45 -0. 60 | <0. 60 | - | - | <0. 20 | 0. 025 | 0. 015 | ||

| 12Cr5Montt | |||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00 -10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0. 025 | 0, 015 | |

| 12Cr9Montt | |||||||||||||

| Stainless Heat Resistant Simbi | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0. 030 | 0. 015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0. 030 | 0. 015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00~13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0. 015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10. 00 -14. 00 | - | 一 | 一 | - | 0.03 | 0. 015 | |

| Aihwa | Tensile MPa | Yield MPa | Nguva refu mushure mekutyoka A/% | Simba rekutora shork kv2/j | Brinell kuoma nhamba | ||

| portrait | transver | portrait | transver | ||||

| kwete zvishoma pane | kwete kupfuura | ||||||

| 10 | 335〜475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410〜550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410〜560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440〜640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415〜560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470〜640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450~600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415〜590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5Montt | 480〜640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460〜640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9Montt | 590—740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9NilO | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | >485 | 170 | 35 | 一 | - | 187 HBW | |

| Kune simbi ine madziro ukobvu isingasviki 5mm chubhu usaite kuomarara kuedza | |||||||

Hydraulic test

Muedzo weHydraulic uchaitirwa pombi dzesimbi imwe neimwe. Iyo yakanyanya test pressure ndeye 20 MPa. Pasi pekumanikidzwa kwekuedza, nguva yekudzikamisa haifaniri kunge iri pasi pe10 s, uye kubuda kwepombi yesimbi hakubvumirwi.

Flattening bvunzo

Muedzo wekufuratira uchaitwa wepombi yesimbi ine dhayamita yekunze inodarika 22 mm

Flaring test

High quality carbon structural simbi uye Stainless (heat-resistant) mapaipi esimbi ane dhayamita rekunze risingapfuuri 76 mm uye ukobvu hwemadziro husingapfuuri 8 mm huchaiswa mukuedzwa kwekuwedzera. Iyo flaring bvunzo ichaitwa pakamuri tembiricha. Iyo yekunze dhayamita yekupisa chiyero cheiyo sampuli mushure meiyo yepamusoro core taper ndeye 60% yekupisa ichasangana nezvinodiwa zvetafura 7. Hapana kuputika kana kuputika kunobvumirwa pamuenzaniso mushure mekuputika. Zvinoenderana nezvinodiwa zveanoda uye zvakacherechedzwa muchibvumirano, iyo alloy simbi yekugadzira inogona kushandiswawo kuwedzera bvunzo.

Nondestructive teste

Mapombi esimbi achave ari pasi pe ultrasonic kukanganisa kutariswa imwe neimwe zvinoenderana nezvinodiwa zveGB / T 5777-2008. Zvinoenderana nezvinodiwa neanokumbira, mamwe maedzo asiri ekuparadza anogona kuwedzerwa mushure menhaurirano pakati pemutengesi neanokumbira uye anoratidzwa muchibvumirano.

Intergranular corrosion test

Intergranular corrosion test ichaitwa isina tsvina (inodzivirira kupisa) pombi yesimbi. Iyo nzira yekuyedza ichave inoenderana nezvinopihwa zveChinese nzira E muGB / T 4334-2008, uye intergranular corrosion maitiro haatenderwe mushure mebvunzo.

Mushure menhaurirano pakati pemutengesi neanokumbira, uye akacherechedzwa muchibvumirano, iye anokumbira anogona kudoma dzimwe nzira dzekuyedza corrosion.

Mafuta, petrochemical, high pressure boiler, kushandiswa kwakakosha kweseamless tube boiler seamless chubhu, geological seamless simbi chubhu uye mafuta seamless chubhu.

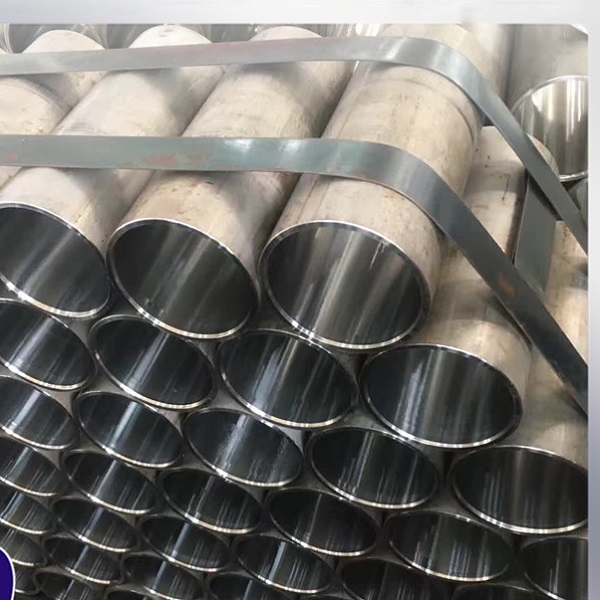

Chemical Component

| brand | Chemical Component (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12~0.18 | 0.40~0.70 | 0.17~0.37 | 0.80~1.10 | 0.40~0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Mechanical Property

| brand | Tensile MPa | Yield MPa | Elongation (%) |

| 15CrMo | 440~640 | 295 | 22 |