Ifekthri Eshibhile yase-China Ikhwalithi Ephakeme Amapayipi Ashiselwe Insimbi Yensimbi Eqondile Eqondile

Uhlolojikelele

"Lawula izinga ngemininingwane, bonisa amandla ngekhwalithi". Ibhizinisi lethu lizamile ukusungula izisebenzi ezisebenza kahle kakhulu nezizinzile futhi lahlola inqubo yokulawula ikhwalithi enhle ye-Straight Carbon Steel Welded Pipes. Ikhwalithi enhle ubukhona befektri, ukugxila ekufuneni kwekhasimende kuwumthombo wokusinda nokuthuthuka kwenkampani, Sinamathela ekuthembekeni nasekusebenzeni kokholo oluphakeme, sibheke phambili ekufikeni kwakho!

Ukuze uthole ipayipi le-carbon steel elishiselwe, kunesidingo sobuchwepheshe obu-2 obuyinhloko ukuthi i-ERW(i-electric resistance weld) kanye ne-SAW (i-submerge arc weld). Amapayipi asebenzisa lobu buchwepheshe womabili asetshenziselwa ikakhulukazi imboni ye-petroleum yokuthutha uwoyela negesi, kodwa wonke anenzuzo yawo, ngakho-ke ukusetshenziswa kuhlukile.

Ipayipi le-ERW lenziwe nge-steel plate, kunomthungo owodwa kuphela oshiselwe, futhi ngenxa yokuthi ulayini oshiselwe wepayipi le-ERW uphuma epayipini likamama, alidingi i-solder flux, ngakho-ke impahla yokukhanda yinhle kakhulu. Futhi ngenxa yezimpawu zayo zokusebenza kahle kakhulu kokukhiqiza, izindleko eziphansi, ukonga impahla, kanye ne-automation elula, uma kuqhathaniswa nepayipi le-SAW, ipayipi le-ERW liyipayipi lensimbi elinomkhiqizo othuthukisiwe osebenza kahle, ikhwalithi eholayo kanye nokusebenza ngokonga okulinganiselwe emkhakheni wokugcinwa kukawoyela negesi. nezokuthutha. Ikakhulukazi landela ukukhula kobuchwepheshe, ikhwalithi uma ulayini oshiselwe iba ngcono kakhulu, ngokusebenzisa ubuchwepheshe obusha, inhloso iwukuqeda ukucindezeleka, ukuthambisa nokucwenga isakhiwo, futhi kuthuthukiswe izici ezibanzi zemishini yendawo ethintekile yokushisela. Lolu hlobo lwepayipi lwe-ERW alukwazi ukuhlukaniswa kuphela i-weld, kodwa futhi i-coefficient ye-weld ifinyelela ku-1, eqaphela ukuhambisana kwesakhiwo sendawo ye-weld ne-base material.

Ubuningi bamanje bezobuchwepheshe be-SAW buphezulu kakhulu, futhi isendlalelo se-flux sivimbela ukulahlekelwa kokushisa okusheshayo futhi sigxilise endaweni ye-soldering. I-arc welding engaphansi kwamanzi inekhwalithi ephezulu ye-weld seam, ukusebenza kahle kokukhiqiza okuphezulu, akukho ukukhanya kwe-arc kanye nentuthu encane. Amapayipi ensimbi afakwe ngaphansi kwe-arc ashiselwe asetshenziswa kakhulu emikhunjini yokucindezela, ukufakwa kwamapayipi, imishayo, amakholomu, uketshezi olunomfutho ophansi, kanye namaphrojekthi wesakhiwo sensimbi. Kodwa embonini kaphethiloli yezwe elithuthukile, ipayipi le-SAW alivunyelwe ukungena ngoba umkhawulo walo, e-China ipayipi le-SAW kuphela elisavunyelwe embonini ye-petroleum enomkhawulo.

Ikhwalithi enhle nentengo ephusile" yizimiso zethu zebhizinisi. Uma unentshisekelo ngemikhiqizo yethu nezisombululo noma unemibuzo, qiniseka ukuthi uzizwa ukhululekile ukusithinta. Sithemba ukusungula ubudlelwano bokubambisana nawe maduze nje.

Isicelo

Isetshenziselwa Ikakhulukazi izingxenye zamandla nengcindezi, futhi ngenjongo evamile yamapayipi omusi, amanzi, igesi nomoya.

Ibanga Eliyinhloko

G.A, GR.B

Ingxenye Yekhemikhali

| Ibanga | Ingxenye %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (ipayipi elingenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (Ipayipi elishiselwe ukumelana) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo F (Ipayipi Elishiselwe Esithandweni) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isamba salezi zakhi ezinhlanu akufanele sibe ngaphezu kuka-1.00%.

B Kulokho kwehla ngo-0.01% kokuqukethwe okuphezulu kwekhabhoni, okuqukethwe okuphezulu kwe-manganese kuvunyelwe ukukhuphuka ngo-0.06%, kodwa umkhawulo angeke udlule u-1.35%.

C Ukwehla ngakunye ngo-0.01% kokuqukethwe kwekhabhoni ephezulu kuzovumela okuqukethwe okuphezulu kwe-manganese ukuthi kukhuphuke ngo-0.06%, kodwa umkhawulo akumele udlule u-1.65%.

Impahla Mechanical

| into | G.A | GR.B |

| amandla okubamba, ≥, psi [MPa] Amandla Okukhiqiza, ≥, psi [MPa] Gauge 2in.noma 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubude obuncane begeji engu-2in. (50mm) izonqunywa ngefomula elandelayo:

e=625000(1940)A0.2/U0.9

e = ubude obuncane begeji engu-2in. (50mm), iphesenti lifinyezwa ku-0.5% eseduze;

A = Ibalwa ngokuhambisana nobubanzi obushiwo bangaphandle beshubhu lokuzisholo noma ububanzi besampula obuqinile kanye nogqinsi olucacisiwe lodonga, futhi lazungezwa endaweni eseduze yesigaba esiphambanayo yesampula eqinile engu-0.01 in.2 (1 mm2), futhi Iqhathaniswa no-0.75in.2 (500mm2), kuye ngokuthi yikuphi okuncane.

U = amandla amancane aqinile abekiwe, i-psi (MPa).

B Ngokuhlanganiswa okuhlukahlukene kosayizi abahlukene bezibonelo zokuhlolwa kwe-tensile namandla anqunyiwe abekiwe, ubude obuncane obudingekayo buboniswa kuThebula X4.1 noma kuThebula X4.2, ngokuya ngokusebenza kwakho.

Isidingo Sokuhlola

Ukuhlolwa kwe-tensile, ukuhlolwa kokugoba, ukuhlolwa kwe-hydrostatic, ukuhlolwa kukagesi okungonakalisi kwama-welds.

Supply Amandla

Ikhono Lokuhlinzeka: Amathani angu-2000 Ngenyanga Ngebanga ngalinye le-ASTM A53/A53M-2012 Ipayipi Lensimbi

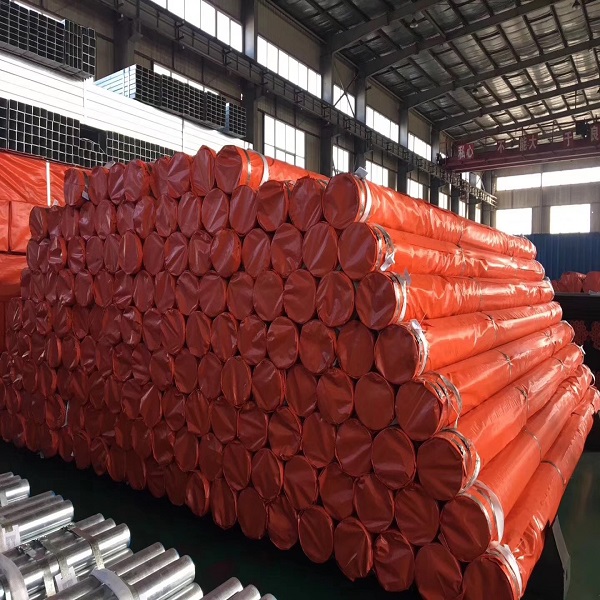

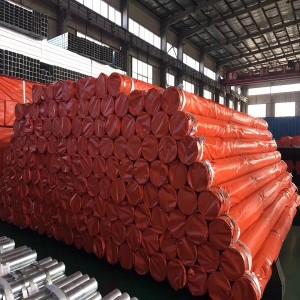

Ukupakisha

Kuyizinqwaba Nasebhokisini Lokhuni Eliqinile

Ukulethwa

Izinsuku ezingu-7-14 uma zisesitokweni, izinsuku ezingu-30-45 zokukhiqiza

Inkokhelo

30% depsoit, 70% L/C noma B/L ikhophi noma 100% L/C lapho ubona