Isampula yamahhala ye-China ASTM A53/BS1387 Ipayipi Lensimbi Elifakwe Intambo Elihlanganisiwe nelihlanganisiwe

Uhlolojikelele

Ilungu ngalinye elivela eqenjini lethu lemali engenayo yokusebenza enkulu lizazisa izimfuneko zamakhasimende kanye nokuxhumana kwenhlangano kwe-ASTM A53/BS1387 Ipayipi Lensimbi Elifakwe Ngamanzi Elishisayo Elishisayo. Sithemba ukuthi singaba umphakeli wakho onokwethenjelwa e-China. Sibheke phambili ukubambisana kwakho .Ngokuhlangenwe nakho kweminyaka engaphezu kwengu-9 kanye neqembu lochwepheshe, sithumele imikhiqizo yethu emazweni amaningi nasezifundeni emhlabeni jikelele. Samukela amakhasimende, izinhlangano zamabhizinisi nabangane abavela kuzo zonke izingxenye zomhlaba ukuze baxhumane nathi futhi bafune ukubambisana ukuze bathole izinzuzo ezifanayo.

I-hot-dip galvanizing inezinzuzo zokugqoka okufanayo, ukunamathela okuqinile nokuphila isikhathi eside. Ukusabela okuyinkimbinkimbi ngokomzimba namakhemikhali kwenzeka phakathi kwe-matrix yepayipi lensimbi nesisombululo sokucwenga esincibilikisiwe ukuze kwakhe ungqimba lwengxubevange ye-zinc-iron olungagqwali olunesakhiwo esihlangene. Isendlalelo se-alloy sihlanganiswe nesendlalelo se-zinc ehlanzekile kanye ne-matrix yepayipi yensimbi. Ngakho-ke, ukumelana kwayo nokugqwala kunamandla.

Kumele kuqashelwe ukuthi ngeminyaka yawo-1960 nawo-1970, amazwe athuthukile emhlabeni aqala ukuthuthukisa izinhlobo ezintsha zamapayipi futhi kancane kancane avala amapayipi anamathani. Ongqongqoshe namakhomishini amane okuhlanganisa nowezokwakha eChina nawo akhiphe umqulu ocacisa ukuthi amapayipi kathayela avaliwe kusukela ngo-2000 kuya phambili. Amapayipi anothayela awavamile ukusetshenziselwa amapayipi amanzi abandayo emiphakathini esanda kwakhiwa, kanti amapayipi anathayela asetshenziselwa amapayipi amanzi ashisayo kweminye imiphakathi.

Isicelo

Isetshenziselwa Ikakhulukazi izingxenye zamandla nengcindezi, futhi ngenjongo evamile yamapayipi omusi, amanzi, igesi nomoya.

Ibanga Eliyinhloko

G.A, GR.B

Ingxenye Yekhemikhali

| Ibanga | Ingxenye %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (ipayipi elingenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (Ipayipi elishiselwe ukumelana) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo F (Ipayipi Elishiselwe Esithandweni) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isamba salezi zakhi ezinhlanu akufanele sibe ngaphezu kuka-1.00%.

B Kulokho kwehla ngo-0.01% kokuqukethwe okuphezulu kwekhabhoni, okuqukethwe okuphezulu kwe-manganese kuvunyelwe ukukhuphuka ngo-0.06%, kodwa umkhawulo angeke udlule u-1.35%.

C Ukwehla ngakunye ngo-0.01% kokuqukethwe kwekhabhoni ephezulu kuzovumela okuqukethwe okuphezulu kwe-manganese ukuthi kukhuphuke ngo-0.06%, kodwa umkhawulo akumele udlule u-1.65%.

Impahla Mechanical

| into | G.A | GR.B |

| amandla okubamba, ≥, psi [MPa] Amandla Okukhiqiza, ≥, psi [MPa] Gauge 2in.noma 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubude obuncane begeji engu-2in. (50mm) izonqunywa ngefomula elandelayo:

e=625000(1940)A0.2/U0.9

e = ubude obuncane begeji engu-2in. (50mm), iphesenti lifinyezwa ku-0.5% eseduze;

A = Ibalwa ngokuhambisana nobubanzi obushiwo bangaphandle beshubhu lokuzisholo noma ububanzi besampula obuqinile kanye nogqinsi olucacisiwe lodonga, futhi lazungezwa endaweni eseduze yesigaba esiphambanayo yesampula eqinile engu-0.01 in.2 (1 mm2), futhi Iqhathaniswa no-0.75in.2 (500mm2), kuye ngokuthi yikuphi okuncane.

U = amandla amancane aqinile abekiwe, i-psi (MPa).

B Ngokuhlanganiswa okuhlukahlukene kosayizi abahlukene bezibonelo zokuhlolwa kwe-tensile namandla anqunyiwe abekiwe, ubude obuncane obudingekayo buboniswa kuThebula X4.1 noma kuThebula X4.2, ngokuya ngokusebenza kwakho.

Isidingo Sokuhlola

Ukuhlolwa kwe-tensile, ukuhlolwa kokugoba, ukuhlolwa kwe-hydrostatic, ukuhlolwa kukagesi okungonakalisi kwama-welds.

Supply Amandla

Ikhono Lokuhlinzeka: Amathani angu-2000 Ngenyanga Ngebanga ngalinye le-ASTM A53/A53M-2012 Ipayipi Lensimbi

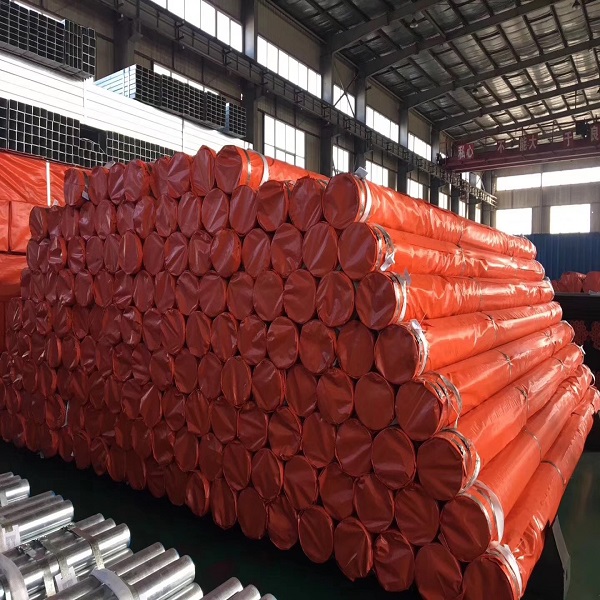

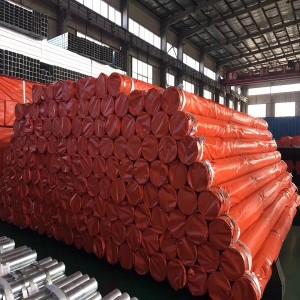

Ukupakisha

Kuyizinqwaba Nasebhokisini Lokhuni Eliqinile

Ukulethwa

Izinsuku ezingu-7-14 uma zisesitokweni, izinsuku ezingu-30-45 zokukhiqiza

Inkokhelo

30% depsoit, 70% L/C noma B/L ikhophi noma 100% L/C lapho ubona