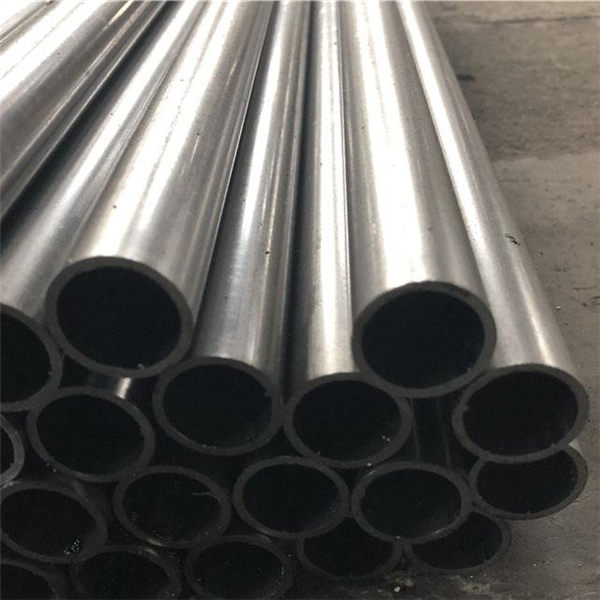

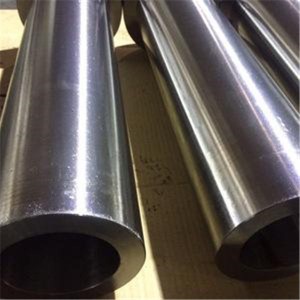

Ikhwalithi enhle yaseChina ASTM A213 Alloy High Pressure High Pressure Seamless Steel Ibanga T11 T12 T13 T22 T1 T2 Pipe/Tube

"Ubuqotho, Ukuqamba Okusha, Ukuqina, kanye Nokusebenza Kahle" kungaba umqondo ophikelelayo webhizinisi lethu kuze kube isikhathi eside ukukhiqiza kanye namakhasimende ukuze kuzwane futhi kuzuzwe inzuzo yokuhlinzeka ngesixazululo samapayipi. Manje sinohlu olukhulu lwepayipi yensimbi ye-Cr Mo alloy ukuze sifeze izingcingo nezidingo zamakhasimende ethu. Njengoba sinabasebenzi abafundile, abahlakaniphile nabanomfutho, sibe nesibopho kuzo zonke izici zokuhlinzekwa kwezixazululo zamapayipi. Ngezinsiza eziningi zekhwalithi ephezulu kanye nesevisi enkulu, siphokophele emgomweni wokuba omunye wabahlinzeki abakhulu bekhambi lepayipi emhlabeni. Silalela ngokucophelela impendulo evela kumakhasimende ethu futhi sinikeze izimpendulo ezisheshayo. Uzozizwa ngokushesha insizakalo yethu enekhono kanye nokunaka.

Mayelana nempahla yepayipi le-Cr Mo, kunezinto eziningi zensimbi ezithinta yona. Ubudlelwano phakathi kwempahla yepayipi nensimbi eyinhloko njengoba ingezansi:

Ikhabhoni (C): Okuqukethwe kwekhabhoni ensimbi kuyenyuka, iphuzu lesivuno, amandla aqinile nobulukhuni buyanda, kodwa izakhiwo zepulasitiki nomthelela ziyehla. Lapho okuqukethwe kwekhabhoni kudlula u-0.23%, ukusebenza kokushisela kwensimbi kuyawohloka, ngakho-ke uma isetshenziselwa ukushisela Okuqukethwe kwekhabhoni yensimbi yesakhiwo esine-alloy ephansi ngokuvamile akudluli ku-0.20%. Okuqukethwe kwekhabhoni ephezulu kuzophinde kunciphise ukumelana nokugqwala komkhathi kwensimbi, futhi insimbi enekhabhoni ephezulu egcekeni lesitoko esivulekile kulula ukugqwala; ngaphezu kwalokho, ikhabhoni ingandisa ukuqina okubandayo nokuzwela ukuguga kwensimbi.

I-Silicon (Si): I-Silicon yengezwa njenge-ejenti yokunciphisa kanye ne-deoxidizer kunqubo yokwenza insimbi, ngakho insimbi ebulewe iqukethe i-silicon engu-0.15-0.30%. I-silicon ingathuthukisa kakhulu umkhawulo wokunwebeka, iphuzu lokukhiqiza namandla ensimbi eqinile, ngakho-ke isetshenziswa kabanzi njengensimbi enwebekayo. Ukwenyuka kwenani le-silicon kuzonciphisa ukusebenza kwe-welding yensimbi.

IManganese (Mn). Enqubweni yokwenza insimbi, i-manganese iyi-deoxidizer enhle ne-desulfurizer. Ngokuvamile, insimbi iqukethe 0.30-0.50% manganese. I-Manganese ingakhuphula amandla nobulukhuni bensimbi, ikhulise ukuqina kwensimbi, ithuthukise ukusebenza okushisayo kwensimbi, futhi inciphise ukusebenza kokushisela kwensimbi.

I-Phosphorus (P): Ngokuvamile, i-phosphorus iyinto eyingozi ensimbi, ekhulisa ukubola okubandayo kwensimbi, ilimaza ukusebenza kokushisela, inciphise ubucwebe bepulasitiki, futhi yonakalise ukusebenza kokugoba okubandayo. Ngakho-ke, okuqukethwe kwe-phosphorus ensimbi ngokuvamile kuyadingeka ukuba kube ngaphansi kuka-0.045%, futhi imfuneko yensimbi yekhwalithi ephezulu iphansi.

Isibabule (S): Isulfure nayo iyisici esiyingozi ngaphansi kwezimo ezijwayelekile. Yenza insimbi ishise ibe brittle, yehlise ukuduka kwensimbi nokuqina, futhi ubangele ukuqhekeka ngesikhathi sokubumba nokuginqika. Isibabule siphinde sibe yingozi ekusebenzeni kokushisela, sinciphisa ukumelana nokugqwala. Ngakho-ke, okuqukethwe kwesibabule ngokuvamile kuyadingeka ukuba kube ngaphansi kuka-0.045%, futhi imfuneko yensimbi yekhwalithi ephezulu iphansi. Ukwengeza i-0.08-0.20% sulphur ensimbi kungathuthukisa ukusebenza kahle, futhi ngokuvamile kubizwa ngokuthi insimbi yokusika mahhala.

I-Vanadium (V): Ukwengeza i-vanadium ensimbi kungacwenga izinhlamvu zesakhiwo futhi kuthuthukise amandla nokuqina.

I-Niobium (Nb): I-Niobium ingacolisa okusanhlamvu futhi ithuthukise ukusebenza kokushisela.

I-Copper (Cu): I-Copper ingathuthukisa amandla nokuqina. Okubi ukuthi kujwayele ukuba nokushisa okushisa ngesikhathi sokusebenza okushisayo, futhi okuqukethwe kwethusi kunsimbi ye-scrap kuvame ukuba phezulu.

I-Aluminium (Al): I-Aluminium iyi-deoxidizer esetshenziswa kakhulu ensimbi. Inani elincane le-aluminium lifakwa ensimbi ukuze kucwengwe okusanhlamvu futhi kuthuthukiswe ukuqina komthelela.

| Okujwayelekile | Grade | OD | Tukukhuphuka | Phawula |

| I-ASTM A106 | 106B 106C | 21.3-914mm | 2-150 mm | ipayipi lensimbi |

| I-ASTM A213 | I-T5 T9 T11 T12 T22 T91 | 19-127 mm | 2-20 mm | Ipayipi yensimbi yokushisa ukushisa |

| I-ASTM A335 | P5 P9 P11 P12 P22 P36 P91 | 60.3-914mm | 2-150 mm | ipayipi lensimbi |

| I-ASTM A333 | Gr6 Gr8 Gr10 | 21.3-914mm | 2-80mm | Ipayipi lensimbi lokushisa okuphansi |

| EN10216-2 | P195GH P235GH P265GH 16Mo3 13CrMo4-5 10CrMo9-10 15NiCuMoNb5-6-4(WB36) X10CrMoVNb9-1 X20CrMoV11-1 | 19-914mm | 2-150 mm | ipayipi lensimbi |

| GB9948 | 10 20 12CrMo 15CrMo 12Cr1MoV 12Cr2Mo 12Cr5Mo 12Cr9Mo | 19-914mm | 2-150 mm | Ipayipi eliqhekeka uwoyela |

| GB6479 | 10 20 Q345BCDE 12CrMo 15CrMo 12Cr2Mo 12Cr5Mo 10MoWVNb 12SiMoVNb | 19-914mm | 2-150 mm | Ishubhu likamanyolo elinomfutho ophezulu |