1. Isingeniso kuipayipi lensimbi engenamthungo

Ipayipi lensimbi elingenamthungo liyipayipi lensimbi elinesiphambano esingenalutho futhi alinamithungo elizungezile. Inamandla aphezulu, ukumelana nokugqwala kanye ne-conductivity enhle yokushisa. Ngenxa yokusebenza kwayo okuhle kakhulu, amapayipi ensimbi angenamthungo asetshenziswa kabanzi emikhakheni ehlukahlukene efanauwoyela, imboni yamakhemikhali, amandla kagesi, kanyeukwakhiwa.

2. Inqubo yokukhiqiza ipayipi lensimbi engenamthungo

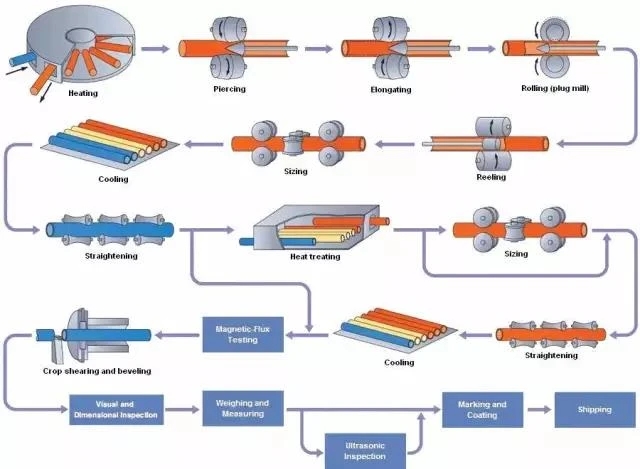

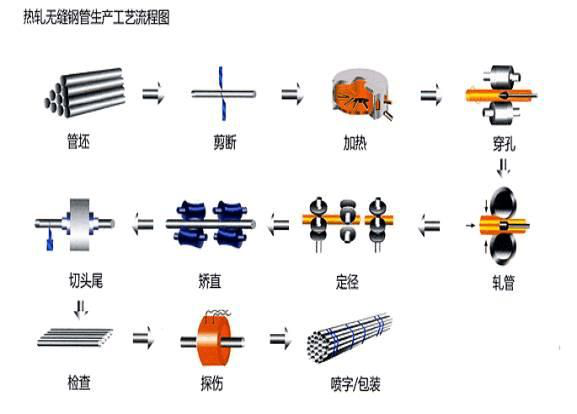

Inqubo yokukhiqiza ipayipi lensimbi engenamthungo ikakhulukazi ihlanganisa lezi zinyathelo ezilandelayo:

a. Lungiselela izinto zokusetshenziswa: Khetha amabhilidi ensimbi afanelekile, adinga indawo ebushelelezi, angabibikho amabhamuza, angabi namifantu, futhi angabi nasici.

b. Ukushisa: Ukushisa i-billet yensimbi ekushiseni okuphezulu ukuze kuyenze ibe ipulasitiki futhi ibe lula ukuyakheka.

c. Ukubhobozwa: I-billet yensimbi eshisayo ibhobozwa eshubhuni elingenalutho ngomshini wokubhoboza, okungukuthi, ipayipi lensimbi elakhiwe ekuqaleni.

d. Ukugoqeka kwamapayipi: Ishubhu elingenalutho ligoqeka izikhathi eziningi ukuze kuncishiswe ububanzi balo, kwandise ukushuba kodonga lwalo, futhi kuqede ukucindezeleka kwangaphakathi.

e. Usayizi: Ipayipi lensimbi ekugcineni libunjwe ngomshini wokulinganisa ukuze ububanzi nodonga lwepayipi lwensimbi luhlangabezane nezidingo ezijwayelekile.

f. Ukupholisa: Ipayipi elimise okwensimbi liyapholiswa ukuze kwandiswe ubulukhuni namandla.

g. Ukuqondisa: Qondisa ipayipi lensimbi elipholile ukuze uqede ukugoba kwalo.

h. Ukuhlolwa kwekhwalithi: Yenza ukuhlolwa kwekhwalithi kumapayipi ensimbi aqediwe, okuhlanganisa nokuhlolwa kosayizi, ukujiya kodonga, ubulukhuni, ikhwalithi yendawo, njll.

3. Inqubo yokukhiqiza ipayipi lensimbi engenamthungo#Ipayipi Lensimbi Elingenamthungo#

3. Inqubo yokukhiqiza ipayipi lensimbi engenamthungo#Ipayipi Lensimbi Elingenamthungo#

Inqubo ethize yokukhiqiza amapayipi ensimbi angenamthungo imi kanje:

a. Lungiselela izinto zokusetshenziswa: Khetha amabhilidi ensimbi afanelekile, angadingi sici, amabhamuza, futhi angabi nemifantu phezulu.

b. Ukushisa: Ukushisa i-billet yensimbi ibe yisimo sokushisa okuphezulu, izinga lokushisa elijwayelekile liyi-1000-1200 ℃.

c. Ukubhobozwa: I-billet yensimbi eshisayo ibhobozwa eshubhuni elingenalutho ngomshini wokubhoboza. Ngalesi sikhathi, ishubhu elingenalutho alikakakhiwa ngokuphelele.

d. Ukugoqeka kwamapayipi: Ishubhu elingenalutho lithunyelwa emshinini wokugoqa wamapayipi ukuze kuginqike kaningi ukuze kuncishiswe ububanzi beshubhu futhi kwandise ukushuba kodonga, kuyilapho kuqeda ukucindezeleka kwangaphakathi.

e. Ukushisa kabusha: Shisisa kabusha ishubhu eligoqiwe lingenalutho ukuze uqede ukucindezeleka okusalayo kwangaphakathi.

f. Usayizi: Ipayipi lensimbi ekugcineni libunjwe ngomshini wokulinganisa ukuze ububanzi nodonga lwepayipi lwensimbi luhlangabezane nezidingo ezijwayelekile.

g. Ukupholisa: Pholisa ipayipi lensimbi elimise okwensimbi, ngokuvamile usebenzisa ukupholisa amanzi noma ukupholisa umoya.

h. Ukuqondisa: Qondisa ipayipi lensimbi elipholile ukuze uqede ukugoba kwalo.

i. Ukuhlolwa kwekhwalithi: Yenza ukuhlolwa kwekhwalithi kumapayipi ensimbi aqediwe, okuhlanganisa nokuhlolwa kosayizi, ukujiya kodonga, ubulukhuni, ikhwalithi yendawo, njll.

Phakathi nenqubo yokukhiqiza, amaphuzu alandelayo adinga ukuqashelwa: okokuqala, izinga kanye nokuzinza kwezinto zokusetshenziswa kufanele kuqinisekiswe; okwesibili, izinga lokushisa nokucindezela kufanele kulawulwe ngokuqinile phakathi nezinqubo zokubhoboza nokugingqa ukuze kugwenywe imifantu kanye nokuguqulwa; ekugcineni, ukulinganisa nokupholisa Ukuzinza nokuqina kwepayipi lensimbi kufanele kugcinwe ngesikhathi senqubo.

4. Ukulawulwa kwekhwalithi yamapayipi ensimbi angenamthungo

Ukuze kuqinisekiswe ikhwalithi yamapayipi ensimbi angenamthungo, izici ezilandelayo zidinga ukulawulwa:

a. Izinto zokusetshenziswa: Sebenzisa amabhilidi ensimbi ekhwalithi ephezulu ukuze uqinisekise ukuthi akukho sici, amabhamuza, noma imifantu phezulu. Ngesikhathi esifanayo, kuyadingeka ukuqinisekisa ukuthi ukwakheka kwamakhemikhali kanye nezakhiwo zemishini yezinto zokusetshenziswa zihlangabezana nezidingo ezijwayelekile.

b. Inqubo yokukhiqiza: Lawula ngokuqinile inqubo ngayinye enqubweni yokukhiqiza ukuze uqinisekise ukuthi ikhwalithi yenqubo ngayinye izinzile futhi ithembekile. Ikakhulukazi phakathi nezinqubo zokubhoboza nokugingqa, izinga lokushisa nokucindezela kufanele kulawulwe ngokuqinile ukuze kugwenywe imifantu kanye nokuguqulwa.

c. Ubukhulu: Yenza ukuhlolwa kwe-dimensional kumapayipi ensimbi aqediwe ukuze uqinisekise ukuthi ububanzi nobukhulu bodonga bawo buhlangabezana nezidingo ezijwayelekile. Amathuluzi okulinganisa akhethekile angasetshenziselwa ukulinganisa, njengama-micrometer, amathuluzi okulinganisa ubukhulu bodonga, njll.

d. Ikhwalithi yobuso: Yenza ukuhlolwa kwekhwalithi yendawo emapayipini ensimbi aqediwe, okuhlanganisa ukuhwaqeka kwendawo, ukuba khona kwemifantu, ukugoqa nokunye ukukhubazeka. Ukuthola kungenziwa ngokusebenzisa ukuhlola okubonakalayo noma amathuluzi okuhlola akhethekile.

e. Isakhiwo se-metallographic: Yenza ukuhlolwa kwesakhiwo se-metallographic epayipini lensimbi eliqediwe ukuze kuqinisekiswe ukuthi isakhiwo salo se-metallographic sihlangabezana nezidingo ezijwayelekile. Ngokuvamile, isibonakhulu sisetshenziselwa ukubuka isakhiwo se-metallographic futhi sihlole ukuthi akhona yini amaphutha amancane.

f. Izakhiwo zemishini: Izakhiwo zemishini zamapayipi ensimbi aqediwe ziyahlolwa, kuhlanganise nobulukhuni, amandla aqinile, amandla okukhiqiza nezinye izinkomba. Imishini yokuhlola i-tensile nezinye izinto zokusebenza zingasetshenziselwa ukuhlola.

Ngokusebenzisa lezi zinyathelo zokulawula izinga eliphezulu, izinga lamapayipi ensimbi angenamthungo lingaqinisekiswa ukuthi lizinzile futhi linokwethenjelwa, lihlangabezana nezidingo zezinkambu zezicelo ezihlukahlukene.

5. Izindawo zokufaka izicelo zamapayipi ensimbi angenamthungo

Amapayipi ensimbi angenamthungo anezinhlobonhlobo zezicelo, ikakhulukazi ezihlanganisa izici ezilandelayo:

a. Imboni kawoyela: isetshenziswa kumapayipi emithombo kawoyela, amapayipi kawoyela kanye namapayipi amakhemikhali embonini ye-petroleum. Amapayipi ensimbi angenamthungo anezici zamandla aphezulu, ukumelana nokugqwala, nokumelana nokushisa okuphezulu, futhi angaqinisekisa ukusebenza okuphephile nokuzinzile kwemboni ye-petroleum.

b. Imboni yamakhemikhali: Embonini yamakhemikhali, amapayipi ensimbi angenamthungo asetshenziswa kakhulu emigqeni ehlukene yokusabela kwamakhemikhali, amapayipi okuthutha uketshezi, njll. Ngenxa yokumelana nokugqwala okuqinile, ingakwazi ukumelana nokuguguleka kwezinto ezihlukahlukene zamakhemikhali, iqinisekisa ukuphepha kokukhiqiza nokusebenza kahle kwemboni yamakhemikhali.

Ipayipi lensimbi elingenamthungo liyinsimbi eyindilinga enengxenye engenalutho futhi ayikho imithungo elizungezile. Inezici zamandla aphezulu, ukumelana nokugqwala, izinga lokushisa eliphezulu nokumelana nokushisa okuphansi. Ngokwezinqubo ezihlukene zokukhiqiza, amapayipi ensimbi angenamthungo angahlukaniswa abe izinhlobo ezimbili: amapayipi ashisayo namapayipi abandayo. Amapayipi ashisayo enziwa ngokushisa amabhilidi ensimbi emazingeni okushisa aphezulu okubhoboza, ukugoqa, ukupholisa nezinye izinqubo, futhi afanele amapayipi ensimbi amakhulu futhi ayinkimbinkimbi; amapayipi abandayo enziwa ngokugoqeka okubandayo ekamelweni lokushisa futhi afanele ukukhiqizwa Amapayipi ensimbi ahlanganisa izingxenye ezincane kanye nokunemba okuphezulu.

Isikhathi sokuthumela: Nov-28-2023