Ukuze kuqinisekiswe ukuthi ikhwalithi yemikhiqizo yamapayipi ensimbi engenamthungo ihlangabezana nezindinganiso, ukuhlolwa okuphelele kwedatha ehlukahlukene njengokubukeka, usayizi, impahla, ukwakheka kwamakhemikhali, izakhiwo zemishini, ukusebenza kwenqubo, nokuhlolwa okungabhubhisi kwamapayipi ensimbi angenamthungo kubalulekile. Ngezansi sizokwethula kafushane izindinganiso zokuhlola ezithinta kakhulu izinga lamapayipi ensimbi angenasici.

Okokuqala, ukuhlolwa kokubukeka kuyisinyathelo sokuqala. Ingaphezulu lamapayipi ensimbi angenamthungo kufanele angabi namagwebu, imihuzuko, ukushintsha kombala, imifantu kanye nezinye iziphambeko. Lezi zinkinga azithinti nje kuphela ubuhle bayo, kodwa zingase futhi zibangele izinkinga ezihlukahlukene ngesikhathi sokusebenzisa umkhiqizo futhi zibangele ngisho nezingozi zokuphepha. Ngakho-ke, ngokuhlolwa kokubukeka, imikhiqizo enekhwalithi ephansi ingahlolwa ekuqaleni.

Okulandelayo ukuhlola usayizi. Ukunemba kobukhulu bamapayipi ensimbi angenamthungo kuthinta ngokuqondile ukusebenza kwawo. Ngakho-ke, imingcele eyinhloko efana nobubanzi, ubukhulu bodonga, nobude bamapayipi ensimbi kufanele kulinganiswe ngokuqinile futhi kulawulwe. Kuphela uma le mingcele yobukhulu ihlangabezana nezidingo ezijwayelekile lapho ukuzinza kwepayipi lensimbi ekufakweni kuqinisekisiwe.

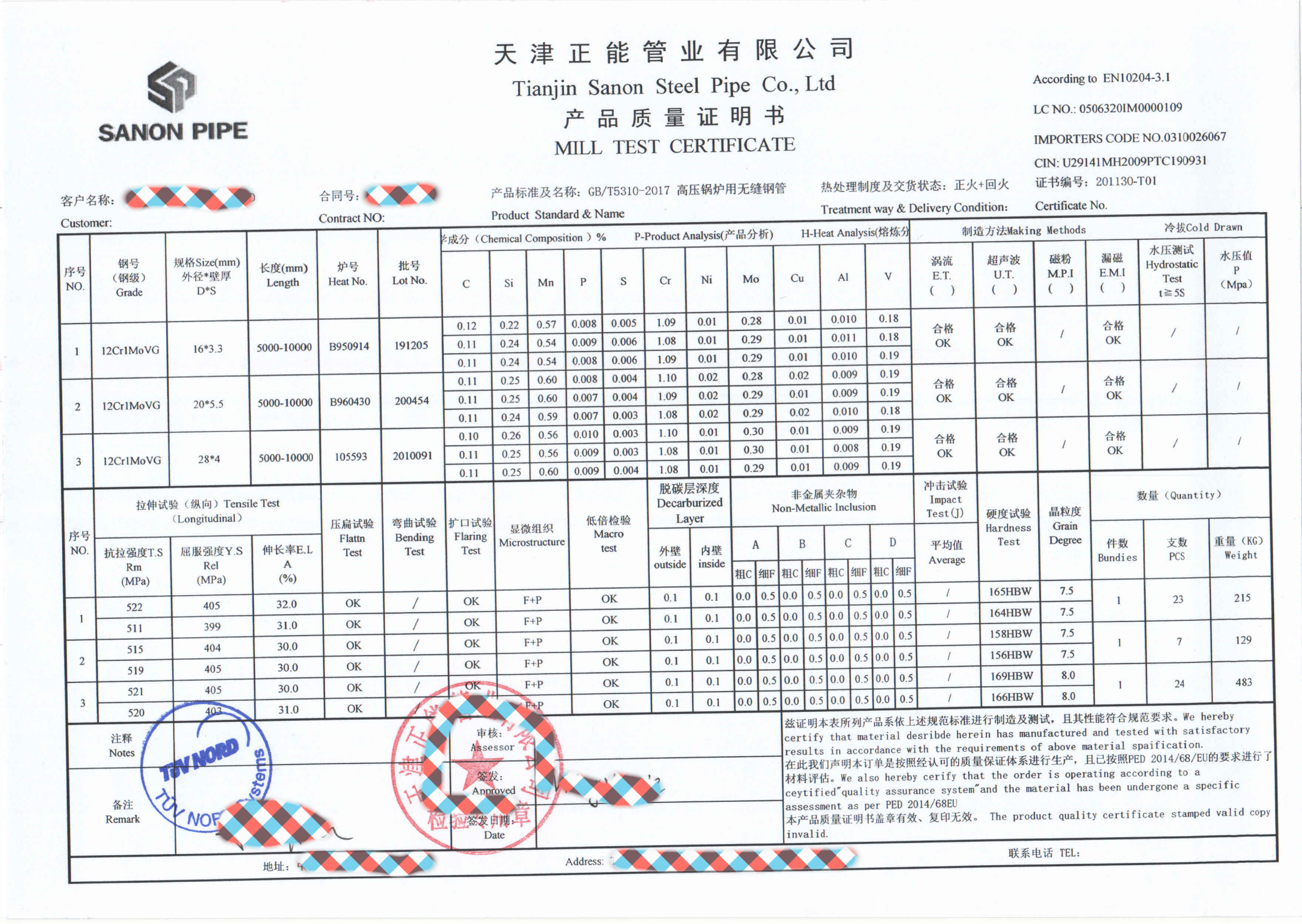

Ukuhlola okubalulekile nakho kuyisixhumanisi esiyinhloko. Izinto zepayipi lensimbi engenamthungo ngokuvamile zihlanganisa izakhi zensimbi ezihlukahlukene, ezifana nekhabhoni, i-manganese, i-silicon, i-phosphorus, njll. Ingxenye yalezi zakhi ithinta ngokuqondile izakhiwo zemishini nokusebenza kwenqubo yamapayipi ensimbi. Ngakho-ke, izinto zokusetshenziswa kufanele zihlolwe ngokuqinile kokwakheka kwamakhemikhali ukuze kuqinisekiswe ukuthi ziyahlangabezana nezindinganiso ezifanele.

Izici zemishini kanye nokuhlolwa kokusebenza kwenqubo nakho kuyizixhumanisi ezibalulekile. Lokhu kuhlola kufaka phakathi ukuhlolwa okuqinile, ukuhlolwa kokuqina komthelela, ukuhlolwa kokuqina, ukuhlolwa kokunwetshwa, njll. Lezi zivivinyo zingabonisa ngokugcwele izici zemishini nezici zokucubungula zamapayipi ensimbi. Ngale datha yokuthola, abakhiqizi bangakhetha izinqubo zokukhiqiza ezifanele zezimo ezihlukene zohlelo lomkhiqizo ukuze kuqinisekiswe ukusebenza komkhiqizo.

Okokugcina, ukuhlola okungabhubhisi nakho kuyindlela ebalulekile yokuhlola izinga lamapayipi ensimbi angenamthungo. Izindlela zokuhlola ezingabhubhi njengokuhlola i-radiographic, ukuhlolwa kwe-ultrasonic, nokuhlolwa kwezinhlayiyana kazibuthe kungathola amaphutha njengokuqhekeka nokufakwa ngaphakathi nangaphezulu kwamapayipi ensimbi. Lezi ziphambeko zinzima ukuzibona ngesikhathi sokuhlolwa okuvamile, kodwa zingase zibe nomthelela omkhulu empilweni yesevisi yepayipi yensimbi. Ngakho-ke, ngokuhlolwa okungabhubhisi, ikhwalithi engokwemvelo yemikhiqizo yamapayipi ensimbi engenamthungo ingaqinisekiswa ngokwengeziwe.

Ngamafuphi, ukuze kuqinisekiswe ikhwalithi yemikhiqizo yamapayipi ensimbi engenamthungo ihlangabezana nezindinganiso, ukuhlolwa okuphelele kwedatha ehlukahlukene kuyisixhumanisi esibalulekile. Lawa mazinga okuhlola awabandakanyi kuphela amapharamitha ayisisekelo njengokubukeka, usayizi, nezinto ezibonakalayo, kodwa futhi ahlanganisa izici eziningi ezifana nezakhiwo zemishini, ukusebenza kwenqubo, nokuhlola okungalimazi. Ngalokhu kuhlolwa okuphelele, izinga lekhwalithi lemikhiqizo yamapayipi ensimbi engenamthungo lingacutshungulwa ngokuphelele ukuze kuqinisekiswe ukuphepha nokuzinza kwawo ngesikhathi sokusetshenziswa.

Isikhathi sokuthumela: Nov-08-2023