Ipayipi lensimbi elingenamthungo libhobozwa yiyo yonke insimbi eyindilinga, futhi ipayipi lensimbi elingashisiseli phezulu libizwa ngokuthi ipayipi lensimbi engenamthungo. Ngokwendlela yokukhiqiza, ipayipi lensimbi elingenamthungo lingahlukaniswa libe ipayipi lensimbi elingenamthungo eligoqwe elishisayo, ipayipi lensimbi elibandayo eligoqelwe elibandayo, ipayipi lensimbi elibandayo elidonswayo, ipayipi lensimbi elingenamthungo, ukugqekeza kwepayipi nokunye. Ngokwesimo sesigaba, ipayipi lensimbi engenamthungo lihlukaniswe ngezinhlobo ezimbili: nxazonke futhi ezimise. Ubukhulu obukhulu bungama-900mm kanti ubukhulu obuncane bungama-4mm. Ngokusetshenziswa okuhlukene, kukhona amapayipi ensimbi angenamthungo aminyene kanye namapayipi ensimbi angenamthungo amancane. Ipayipi lensimbi engenamthungo lisetshenziselwa ikakhulukazi ipayipi lokumba le-petroleum geological, i-petrochemicalipayipi eliqhekeka, ipayipi le-boiler, ipayipi elithwalayo kanyeipayipi yensimbi yesakhiwo enembayo ephezuluezezimoto, ogandaganda kanye nezokundiza.

Ngokusho ukusetshenziswa ihlukaniswe inhloso jikelele (amanzi, igesi amapayipi kanye izingxenye zesakhiwo, izingxenye mechanical) kanye ekhethekile (for boilers, ukuhlola geological, ama-bearings, ukumelana acid, njll) izigaba ezimbili.

Inhloso evamile yepayipi lensimbi engenamthungo igoqwa ngensimbi evamile ye-carbon structural, insimbi yesakhiwo sengxubevange ephansi noma insimbi yesakhiwo sengxubevange, futhi inomphumela omkhulu kakhulu, osetshenziswa kakhulu njengepayipi noma ingxenye yesakhiwo yokudlulisa uketshezi. Kunezinhlobo eziningi zamapayipi angenamthungo ngezinjongo ezikhethekile, njengamapayipi angenamthungo abhayela, amapayipi amandla amakhemikhali, amapayipi angenamthungo we-geological kanye namapayipi angenamthungo ka-petroleum. Ipayipi lensimbi elingenamthungo linendawo ephambanayo engenalutho futhi lisetshenziswa kakhulu njengepayipi lokudlulisa uketshezi, njengamapayipi okuhambisa uwoyela, igesi yemvelo, igesi, amanzi nezinye izinto eziqinile.

Inqubo yokukhiqiza ipayipi lensimbi engenamthungo:

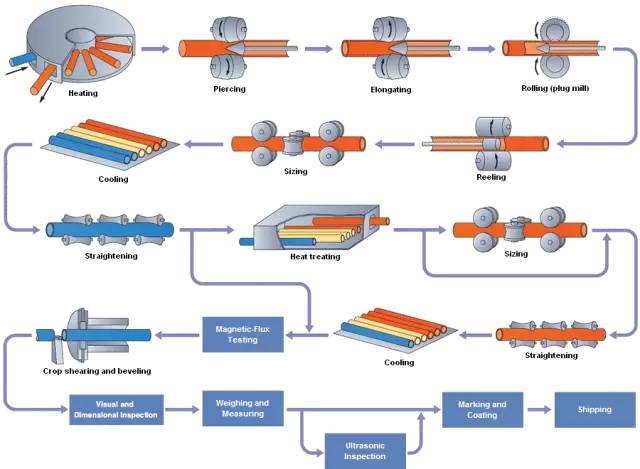

① Inqubo yokukhiqiza eyinhloko yepayipi lensimbi elingenamthungo eligoqelwe ngokushisayo (△ Inqubo yokuhlola enkulu) :

Ukulungiselela nokuhlola △→ Ukushisa → ukubhoboza → Ukugoqa → ukushisisa kabusha → Ukulinganisa ubukhulu → Ukwelashwa kokushisa △→ Ukuqondisa → Ukuqeda → Ukuhlola △ (okungonakali, ngokomzimba namakhemikhali, ukuhlolwa kwetafula) → indawo yokugcina

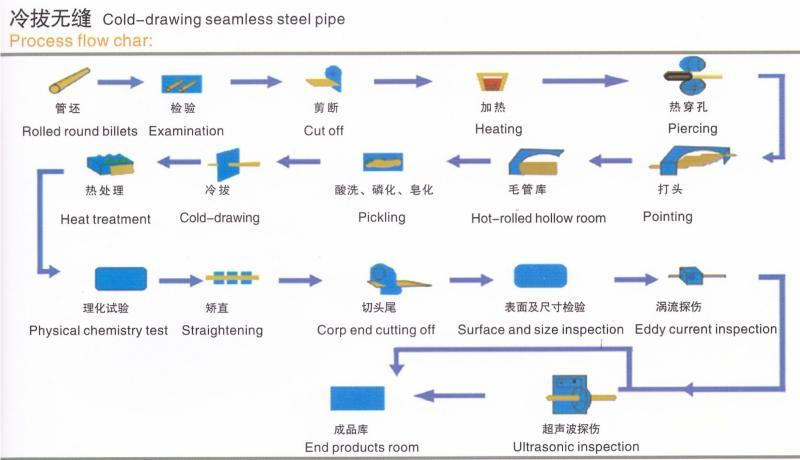

② Inqubo yokukhiqiza eyinhloko yepayipi lensimbi eligoqiwe (elidwetshiwe) elibandayo:

Ukulungiselela okungenalutho → ukugcotshwa kwe-pickle → Ukugoqa okubandayo (umdwebo) → Ukwelashwa kokushisa → ukuqondisa → ukuqeda → ukuhlola

Inqubo evamile yokukhiqiza ipayipi lensimbi engenamthungo ingahlukaniswa ibe izinhlobo ezimbili zomdwebo obandayo kanye nokuginqika okushisayo, inqubo yokukhiqiza ipayipi lensimbi engenamthungo ebandayo ngokuvamile iyinkimbinkimbi kakhulu kunokuginqika okushisayo, i-tube billet kuqala ukufeza ukugoqa okuqhubekayo kwama-roller amathathu, i-extrusion ngemuva kokuhlolwa kokulinganisa, uma indawo engaphezulu ingaphenduli emfantwini ngemuva kweshubhu eliyindilinga elizosikwa ngomshini wokusika, ukusika ukukhula okungenalutho kwemitha eyodwa. Bese ufaka inqubo ye-annealing, i-annealing nge-acidic liquid pickling, i-pickling kufanele inake ukuthi kukhona inani elikhulu lama-bubbles ebusweni, uma kunenani elikhulu lama-bubbles, okubonisa ukuthi ikhwalithi yepayipi yensimbi ayikwazi ukuhlangabezana nezindinganiso ezihambisanayo. Ukubonakala kwepayipi lensimbi engenamthungo eligoqelwe ngokubanda lifushane kunalelo lepayipi lensimbi eligoqwe elishisayo eligoqelwe, ubukhulu bodonga lwepayipi lensimbi engenamthungo eligoqelwe ngokubanda ngokuvamile lincane kunalelo lepayipi lensimbi eligoqelwe elishisayo eligoqelwe, kodwa ubuso bubukeka bukhanya kakhulu kunalelo payipi lensimbi eliqinile elinezindonga, indawo engaphezulu ayimbi kakhulu, futhi i-burrr ayiningi kakhulu.

Isimo sokulethwa kwepayipi lensimbi engenamthungo eligoqwe elishisayo ngokuvamile lilethwa ngemva kokwelashwa kokushisa okugoqiwe okushisayo. Ipayipi lensimbi elingenamthungo elishisayo eligoqelwe ngemva kokuhlolwa kwekhwalithi ukuze lidlule ekukhethweni okuqinile kwabasebenzi, ngemva kokuhlolwa kwekhwalithi ukuze kuqhutshwe uwoyela ongaphezulu, bese kulandelwa inani lokuhlolwa okubandayo komdwebo, ukwelashwa okugoqayo okushisayo ukuze kwenziwe ukuhlolwa kokubhoboza, uma ukukhuliswa kwembobo kukhulu kakhulu ukuba kungaqondisa. Ngemva kokuqondisa, ithunyelwa emshinini wokubona amaphutha ngedivayisi yokudlulisela ukuze kuhlolwe amaphutha, futhi ekugcineni ilebulwe, ifomethwe futhi ibekwe endaweni yokugcina impahla.

Ishubhu eliyindilinga alinalutho → ukushisisa → ukubhobozwa → ukugoqeka kwe-skew yamaroll amathathu, ukugoqeka okuqhubekayo noma okuphumayo → Ukuhlubula → ukusika (noma ukunciphisa) → Ukupholisa → ukuqondisa → ukuhlolwa komfutho wamanzi (noma ukuhlola) → Ukumaka → Ipayipi lensimbi elingenamthungo endaweni yokugcina lenziwa ngensimbi yensimbi noma ishubhu eliqinile lingabi nalutho bese lenza ipayipi elibandayo eligoqayo bese lenza imbobo ebandayo. umdwebo. Ukucaciswa kwepayipi lensimbi engenamthungo kuvezwa ububanzi obungaphandle * ukushuba kodonga lwamamilimitha.

Ububanzi bangaphandle bepayipi elingenamthungo eligoqwe elishisayo ngokuvamile likhulu kuno-32mm, ukushuba kodonga buyi-2.5-200mm, ububanzi obungaphandle bepayipi lensimbi eligoqwe elibandayo bungaba ngu-6mm, ukushuba kodonga kungaba ngu-0.25mm, ububanzi obungaphandle bepayipi elinezindonga ezincane bungaba ngu-5mm, ukujiya kodonga kungaphansi kuka-5mm nosayizi ongaphansi kuka-5mm. ipayipi elingenamthungo eligoqwe elishisayo.

Isikhathi sokuthumela: Aug-28-2023