Supply OEM China Oil and Gas Steel Line Pipe API 5L Psl2 X42/X46/X60/X70 Seamless Carbon Steel Pipe

Uhlolojikelele

Inkampani yethu iphikelela ngaso sonke isikhathi ngenqubomgomo yekhwalithi "yekhwalithi yomkhiqizo omuhle iyisisekelo sokusinda kwebhizinisi; ukugcwaliseka komthengi kuzoba iphuzu nesiphetho senkampani; ukuthuthukiswa okuqhubekayo kuwukuphishekela abasebenzi kwaphakade" kanye nenjongo engaguquki "yokuba nesithunzi kuqala , shopper first" ye-API 5L Line Pipe, Sivamise ukuhlinzeka ngokuthengiswayo kwekhwalithi ephezulu kakhulu nosizo olukhulu kubasebenzisi abaningi bebhizinisi nabahwebi . Siyakwamukela ngokufudumele ukuze usinamathisele, sisungule ndawonye, futhi sithuthukise amaphupho. Inkampani yethu ibheka ukuthi ukuthengisa akukhona nje ukuzuza inzuzo kodwa futhi kwazisa isiko lenkampani yethu emhlabeni wonke. Ngakho-ke sisebenza kanzima ukukunikeza isevisi yenhliziyo yonke futhi sizimisele ukwethula inani elincintisana kakhulu emakethe.

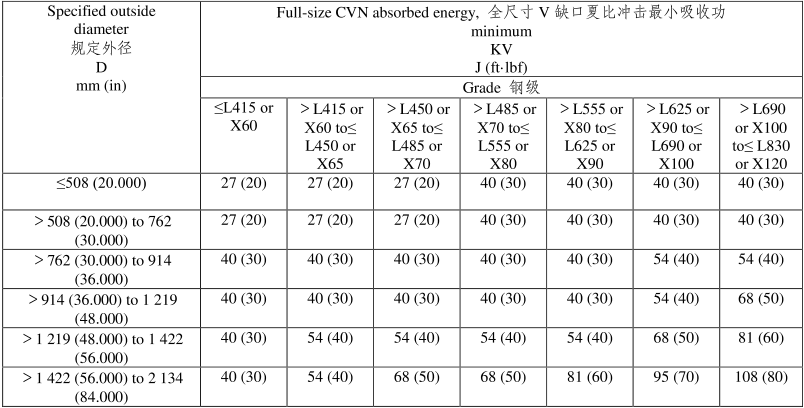

Epayipini lomugqa we-PSL2, i-API 5L idinga ukuhlolwa komthelela we-Charpy(API 5L akuyona imininingwane eqondile yokuhlolwa kokuphuka, kodwa ukuqina kokuphuka okubonisiwe kungabonakala ngokuhlolwa komthelela noma ukwehlisa amandla okumunca izinyembezi kanye nendawo yokugunda). Izinga elijwayelekile lidinga isethi eyodwa izibonelo ezi-3(usayizi ogcwele), izinga lokushisa lokuhlola ngu-0℃, uma kunezidingo, izinga lokushisa lokuhlola eliphansi liyamukeleka. Ivelu yokuhlola ngayinye yanoma yiziphi izingcezu zokuhlola izoba ≥75 wesilinganiso esincane esidingekayo (sesethi yezingcezu ezi-3 zokuhlola) amunca inani le-enengy. Ngezansi isidingo sokumunca amandla wepayipi le-PSL2:

Isicelo

Ipayipi lisetshenziselwa ukuthutha uwoyela, isitimu namanzi adonswa phansi kuya embonini kawoyela negesi ngokusebenzisa ipayipi.

Ibanga Eliyinhloko

Ibanga lensimbi yepayipi ye-API 5L: Gr.B X42 X52 X60 X65 X70

Ingxenye Yekhemikhali

| Ibanga Lensimbi (Igama Lensimbi) | Ingxenyana Enkulu, Ngokusekelwe Ekushiseni Nokuhlaziywa Komkhiqizoa,g% | |||||||

| C | Mn | P | S | V | Nb | Ti | ||

| ubuningi b | ubuningi b | imiz | ubuningi | ubuningi | ubuningi | ubuningi | ubuningi | |

| Ipayipi Elingenamthungo | ||||||||

| I-L175 noma i-A25 | 0.21 | 0.60 | - | 0.030 | 0.030 | - | - | - |

| I-L175P noma i-A25P | 0.21 | 0.60 | 0.045 | 0.080 | 0.030 | - | - | - |

| L210 noma A | 0.22 | 0.90 | - | 0.030 | 0.030 | - | - | - |

| L245 noma B | 0.28 | 1.20 | - | 0.030 | 0.030 | c,d | c,d | d |

| I-L290 noma i-X42 | 0.28 | 1.30 | - | 0.030 | 0.030 | d | d | d |

| I-L320 noma i-X46 | 0.28 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L360 noma i-X52 | 0.28 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L390 noma i-X56 | 0.28 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L415 noma i-X60 | 0.28 e | 1.40 e | - | 0.030 | 0.030 | f | f | f |

| I-L450 noma i-X65 | 0.28 e | 1.40 e | - | 0.030 | 0.030 | f | f | f |

| I-L485 noma i-X70 | 0.28 e | 1.40 e | - | 0.030 | 0.030 | f | f | f |

| Ipayipi elishiselwe | ||||||||

| I-L175 noma i-A25 | 0.21 | 0.60 | - | 0.030 | 0.030 | - | - | - |

| I-L175P noma i-A25P | 0.21 | 0.60 | 0.045 | 0.080 | 0.030 | - | - | - |

| L210 noma A | 0.22 | 0.90 | - | 0.030 | 0.030 | - | - | - |

| L245 noma B | 0.26 | 1.20 | - | 0.030 | 0.030 | c,d | c,d | d |

| I-L290 noma i-X42 | 0.26 | 1.30 | - | 0.030 | 0.030 | d | d | d |

| I-L320 noma i-X46 | 0.26 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L360 noma i-X52 | 0.26 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L390 noma i-X56 | 0.26 | 1.40 | - | 0.030 | 0.030 | d | d | d |

| I-L415 noma i-X60 | 0.26 e | 1.40 e | - | 0.030 | 0.030 | f | f | f |

| I-L450 noma i-X65 | 0.26 e | 1.45 e | - | 0.030 | 0.030 | f | f | f |

| I-L485 noma i-X70 | 0.26 e | 1.65 e | - | 0.030 | 0.030 | f | f | f |

| a Cu ≤ 0.50 %; Ni ≤ 0.50 %; Cr ≤ 0.50 % kanye ne-Mo ≤ 0.15 %. b Ekunciphiseni ngakunye ngo-0.01 % ngaphansi kwesilinganiso esiphezulu esibekiwe sekhabhoni, ukunyuka ngo-0.05 % ngaphezu kwesilinganiso esiphezulu esishiwo ku-Mn kuvumelekile, kuze kufike ku-1.65 % kumabanga ≥ L245 noma B, kodwa ≤ L360 noma X52; kuze kufike ku-1.75 % kumabanga > L360 noma X52, kodwa <L485 noma X70; futhi kuze kufike ku-2.00 % weBanga L485 noma X70. c Ngaphandle uma kuvunyelwene ngenye indlela, Nb + V ≤ 0.06 %. d Nb + V + Ti ≤ 0.15 %. e Ngaphandle uma kuvunyelwene ngenye indlela. f Ngaphandle kwalapho kuvunyelwene ngenye indlela, Nb + V + Ti ≤ 0.15 %. g Akukho ukwengeza ngamabomu kuka-B okuvunyelwe futhi okusele okungu-B ≤ 0.001 %. | ||||||||

Impahla Mechanical

|

Ibanga lePipe | Ipayipi Lomzimba Wepayipi Elingenamthungo nelishiselwe | I-Weld Seam ye-EW, LW, SAW, ne-COWIpayipi | ||

| Isivuno Amandlaa Rt0.5 | Amandla Okuqinaa Rm | Ukwelula(ku-50 mm noma 2 in.)Af | Amandla Okuqinab Rm | |

| I-MPa (psi) | I-MPa (psi) | % | I-MPa (psi) | |

| imiz | imiz | imiz | imiz | |

| I-L175 noma i-A25 | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| I-L175P noma i-A25P | 175 (25,400) | 310 (45,000) | c | 310 (45,000) |

| L210 noma A | 210 (30,500) | 335 (48,600) | c | 335 (48,600) |

| L245 noma B | 245 (35,500) | 415 (60,200) | c | 415 (60,200) |

| I-L290 noma i-X42 | 290 (42,100) | 415 (60,200) | c | 415 (60,200) |

| I-L320 noma i-X46 | 320 (46,400) | 435 (63,100) | c | 435 (63,100) |

| I-L360 noma i-X52 | 360 (52,200) | 460 (66,700) | c | 460 (66,700) |

| I-L390 noma i-X56 | 390 (56,600) | 490 (71,100) | c | 490 (71,100) |

| I-L415 noma i-X60 | 415 (60,200) | 520 (75,400) | c | 520 (75,400) |

| I-L450 noma i-X65 | 450 (65,300) | 535 (77,600) | c | 535 (77,600) |

| I-L485 noma i-X70 | 485 (70,300) | 570 (82,700) | c | 570 (82,700) |

| a Emabangeni aphakathi nendawo, umehluko phakathi kwamandla amancane okudonsa ashiwo kanye namandla amancane ashiwo ebhodini lamapayipi kuyoba njengoba kunikiwe etafuleni lebanga eliphezulu elilandelayo.b Emabangeni amaphakathi, ubuncane bamandla obuncane obuqinile obushiwo be-weld seam izoba yinani elifanayo nalelo elalinqunyelwe umzimba wepayipi kusetshenziswa umbhalo waphansi a).c Ubude obuncane obucacisiwe,Af, evezwe ngamaphesenti futhi yafinyezwa kumaphesenti aseduze, izoba njengokunqunywa kusetshenziswa isibalo esilandelayo:

lapho C unyaka ka-1940 wokubala kusetshenziswa amayunithi e-SI kanye nezi-625,000 zokubala kusetshenziswa amayunithi e-USC; AI-xc iyindawo esebenzayo yokuhlola i-tensile test piece, evezwa ngamamilimitha ayisikwele (amayintshi ayisikwele), kanjena: I-1) ngezingcezu zokuhlola eziyisiyingi, i-130 mm2 (0.20 in.2) ye-12.7 mm (0.500 in.) kanye no-8.9 mm (0.350 in.) izingcezu zokuhlola ububanzi; 65 mm2 (0.10 in.2) ngo-6.4 mm (0.250 in.) izingcezu zokuhlola ububanzi; 2) ngezingcezu zokuhlola ezigcwele, okungaphansi kuka-a) 485 mm2 (0.75 in.2) kanye b) nendawo enqamula ingxenye yocezu lokuhlola, etholakala kusetshenziswa ububanzi obushiwo bangaphandle kanye nobukhulu bodonga obushiwo bepayipi, ukuzungeza ku-10 mm2 eseduze (0.01 ku-2); 3) izingcezu zokuhlolwa kwe-strip, okungaphansi kuka-a) 485 mm2 (0.75 in.2) kanye b) nendawo enqamula ingxenye yesiqeshana sokuhlola, etholakala kusetshenziswa ububanzi obubekiwe besiqephu sokuhlola kanye nobukhulu bodonga obucacisiwe bepayipi. , ifinyezwe ku-10 mm2 eseduze (0.01 ku-2); U amandla okuqina amancane ashiwo, avezwa ngama-megapascals (amaphawundi ngeyintshi yesikwele). | ||||

Ngaphandle kobubanzi, ngaphandle kokuyindilinga nokuqina kodonga

| Kucaciswe Ngaphandle Ububanzi D (ku) | Ukubekezelela Ububanzi, amayintshi d | Ukubekezelelana Okungaphandle Kwe-Roundness ku | ||||

| Ipayipi ngaphandle kokuphela a | Isiphetho sepayipi a,b,c | Ipayipi ngaphandle kokuphela a | Ipayipi End a,b,c | |||

| Ipayipi le-SMLS | Ipayipi elishiselwe | Ipayipi le-SMLS | Ipayipi elishiselwe | |||

| < 2.375 | -0.031 ukuze + 0.016 | - 0.031 ukuze + 0.016 | 0.048 | 0.036 | ||

| ≥2.375 kuya ku-6.625 | 0.020D ye | 0.015D ye | ||||

| +/- 0.0075D | - 0.016 ukuze + 0.063 | D/t≤75 | D/t≤75 | |||

| Ngesivumelwano se | Ngesivumelwano se | |||||

| > 6.625 ukuze 24.000 | +/- 0.0075D | +/- 0.0075D, kodwa ubuningi obungu-0.125 | +/- 0.005D, kodwa ubuningi obungu-0.063 | 0.020D | 0.015D | |

| > 24 kuya ku-56 | +/- 0.01D | +/- 0.005D kodwa ubuningi be-0.160 | +/- 0.079 | +/- 0.063 | 0.015D kodwa ubuningi obungu-0.060 | 0.01D kodwa ubuningi obungu-0.500 |

| Ngoba | Ngoba | |||||

| D/t≤75 | D/t≤75 | |||||

| Ngesivumelwano | Ngesivumelwano | |||||

| okwe | okwe | |||||

| D/t≤75 | D/t≤75 | |||||

| >56 | Njengoba kuvunyelwene | |||||

| a. Ukuphela kwepayipi kuhlanganisa ubude obungu-4 ekudleni ngakunye komkhawulo wepayipi | ||||||

| b. Epayipini le-SMLS ukubekezelela kuyasebenza ku-t≤0.984in futhi ukubekezelelwa kwepayipi eliwugqinsi kuzoba njengoba kuvunyelwene. | ||||||

| c. Epayipini elinwetshiwe eline-D≥8.625in kanye nepayipi elinganwetshiwe, ukubekezelela ububanzi kanye nokubekezelela ngaphandle kwendingilizi kungase kunqunywe kusetshenziswa i-diameter yangaphakathi ebaliwe noma kukalwe i-diameter yangaphakathi kune-OD eshiwo. | ||||||

| d. Ukunquma ukuthobelana nokubekezelelana kobubanzi, ububanzi bepayipi buchazwa njengesiyingi sepayipi kunoma iyiphi indiza eyisiyingi ehlukaniswa nge-Pi. | ||||||

| Ukujiya kodonga | Ukubekezelelana a |

| t amayintshi | amayintshi |

| Ipayipi le-SMLS b | |

| ≤ 0.157 | -1.2 |

| > 0.157 kuya ku-<0.948 | + 0.150t / – 0.125t |

| ≥ 0.984 | + 0.146 noma + 0.1t, noma yikuphi okukhulu kunakho |

| – 0.120 noma – 0.1t, kuye ngokuthi iyiphi enkulu | |

| Ipayipi elishiselwe c,d | |

| ≤ 0.197 | +/- 0.020 |

| > 0.197 ukuze <0.591 | +/- 0.1t |

| ≥ 0.591 | +/- 0.060 |

| a. Uma i-oda lokuthenga licacisa ukubekezelela kokususa ukujiya kodonga okuncane kunenani elisebenzayo elinikezwe kuleli thebula, ukubekezelela okungeziwe kogqinsi lwezindonga kuzokwenyuswa ngenani elanele ukuze kugcinwe ububanzi obusebenzayo bokubekezelelana. | |

| b. Epayipini eline-D≥ 14.000 in kanye no-t≥0.984in, ukubekezelela ukujiya kodonga endaweni kungase kudlule ukubekezelela ukushuba kodonga ngo-0.05t eyengeziwe inqobo nje uma ukubekezelela okungeziwe kwesisindo kungeqiwe. | |

| c. Ukubekezelela okungeziwe kokuqina kodonga akusebenzi endaweni yokushisela | |

| d. Bona imininingwane egcwele ye-API5L ukuze uthole imininingwane egcwele | |

Ukubekezelelana

Isidingo Sokuhlola

Ukuhlolwa kwe-Hydrostatic

Ipayipi ukumelana nokuhlolwa kwe-hydrostatic ngaphandle kokuvuza ngomthungo we-weld noma umzimba wepayipi. Amajoyinti akudingeki ahlolwe i-hydrostatic inqobo nje uma izigaba zamapayipi ezisetshenzisiwe zihlolwe ngempumelelo.

Goba ukuhlolwa

Akukho mifantu ezokwenzeka kunoma iyiphi ingxenye yesiqeshana sokuhlola futhi akukho kuvulwa kwe-weld okuzokwenzeka.

Ukuhlolwa kokucaba

Indlela yokwamukela yokuhlolwa kokucaba izoba:

- EW amapayipi D<12.750 in:

- I-X60 ene-T 500in. Ngeke kube khona ukuvulwa kwe-weld ngaphambi kokuba ibanga phakathi kwamapuleti libe ngaphansi kwama-66% obubanzi bangaphandle bokuqala. Kuwo wonke amabanga nodonga, 50%.

- Epayipini eline-D/t> 10, akumele kuvuleke i-weld ngaphambi kokuba ibanga phakathi kwamapuleti libe ngaphansi kuka-30% we-diameter yasekuqaleni yangaphandle.

- Ukuze uthole abanye osayizi bheka incazelo egcwele ye-API 5L.

Ukuhlolwa komthelela we-CVN kwe-PSL2

Osayizi abaningi bamapayipi e-PSL2 namabanga adinga i-CVN. Ipayipi elingenamthungo kufanele lihlolwe emzimbeni. Ipayipi elishiselwe kufanele lihlolwe emzimbeni, ukushiselwa kwamapayipi nendawo ethinteke ukushisa. Bheka ukucaciswa okugcwele kwe-API 5L kweshadi losayizi namabanga kanye namavelu wamandla amuncwa adingekayo.

`R$D`HBVLT0N{MJJ1.png)