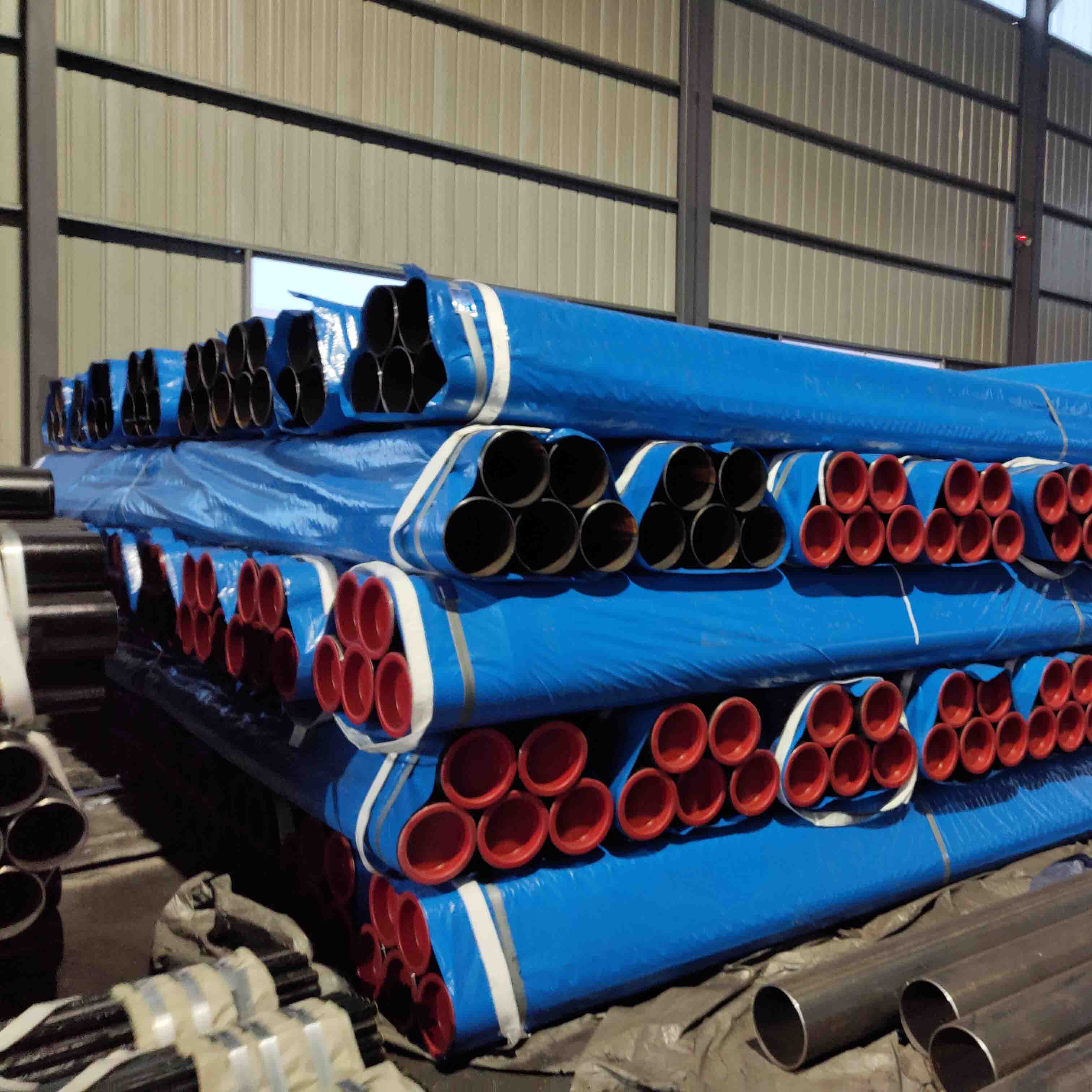

Carbon ígwè ọkpọkọ

| Ọkọlọtọ:ASTM SA106 | Alloy ma ọ bụ bụghị: Ọ bụghị |

| Otu ọkwa: GR.A,GR.B,GR.C wdg | Ngwa: Fluid Pipe |

| Ọkpụrụkpụ: 1-100 mm | Ọgwụgwọ dị n'elu: Dị ka ihe ndị ahịa chọrọ |

| Dayameta dị n'èzí (Gburugburu): 10 - 1000 mm | Usoro: Hot Rolled |

| Ogologo: Ogologo ogologo ma ọ bụ ogologo enweghị usoro | Ọgwụgwọ okpomọkụ: Annealing / normalizing |

| Ụdị ngalaba: Gburugburu | Ọkụ Pụrụ Iche: Okpomọkụ dị elu |

| Ebe Mmalite: China | Ojiji: Mwube, Ụgbọ njem mmiri |

| Asambodo: ISO9001:2008 | Nnwale: ECT/CNV/NDT |

Ọkpụkpụ ígwè na-enweghị ntụpọ maka ọrụ okpomọkụ dị eluASTM A106, adabara elu okpomọkụ, Ọ na-ọtụtụ ebe na mmanụ ala, chemical ụlọ ọrụ, ji esi mmiri ọkụ, ike ọdụ, ụgbọ mmiri, ígwè n'ichepụta, ụgbọala, ụgbọ elu, aerospace, ike, geology, ewu na agha ụlọ ọrụ na ndị ọzọ na ọrụ.

Ọkwa nke igwe nrụpụta carbon dị elu: GR.A, GR.B, GR.C

| Nhazi, ( | |||

| Ọkwa A | Ọkwa B | Ọkwa C | |

| Carbon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0,035 | 0,035 | 0,035 |

| Sulfur, max | 0,035 | 0,035 | 0,035 |

| Silikoni, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Ọla kọpa, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Maka mbelata ọ bụla nke 0.01% n'okpuru oke carbon akọwapụtara, mmụba nke 0.06% manganese karịa nke akọwapụtara ka a ga-ahapụ ruo oke nke 1.35%. | |||

| B Ọ gwụla ma onye zụrụ ya akọwapụtaghị ya, maka mbelata ọ bụla nke 0.01% n'okpuru oke carbon a kapịrị ọnụ, mmụba nke 0.06% manganese karịa nke akọwapụtara ka a ga-ahapụ ruo oke 1.65%. | |||

| C ihe ise a jikọtara agaghị agafe 1%. | |||

| Ọkwa A | Ọkwa B | Ọkwa C | ||||||

| Ike tensile, min, psi(MPa) | 48 000 (330) | 60000 (415) | 70000 (485) | |||||

| Ike mpụta, min, psi(MPa) | 30000 (205) | 35 000 (240) | 40000 (275) | |||||

| Ogologo ogologo | Transverse | Ogologo ogologo | Transverse | Ogologo ogologo | Transverse | |||

| Mgbatị n'ime inch 2 (50 mm), nkeji, % Basic kacha nta elongation transverse warara ule, na niile obere nha nwalere na zuru ngalaba | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Mgbe ọkọlọtọ gburugburu 2-in. (50-mm) a na-eji ihe nlere anya ogologo nlele | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Maka ule eriri ogologo ogologo | A | A | A | |||||

| Maka ule ntụgharị ntụgharị, mwepu maka 1/32-in ọ bụla. (0.8-mm) mbelata nke mgbidi dị n'okpuru 5/16 inch (7.9 mm) site na ntinye kacha nta nke kacha nta nke pasent ndị a ga-eme. | 1.25 | 1.00 | 1.00 | |||||

| A ga-ekpebi elongation kacha nta na inch 2 (50 mm) site na nha nha ndị a: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| maka nkeji inch-paụnd, na | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| maka nkeji SI, | ||||||||

| ebe: e = elongation kacha nta na 2 in. (50 mm), %, gbachie na 0.5% kacha nso, A = mpaghara obe nke ihe nlere ule erughị ala, in.2 (mm2), dabere na nke akọwapụtara n'èzí ma ọ bụ n'ọnụ ọnụ nke akọwapụtara n'èzí dayameta ma ọ bụ obosara ihe atụ na ọkpụrụkpụ mgbidi akọwapụtara, gbachie na 0.01 in.2 (1 mm2) kacha nso. . (Ọ bụrụ na mpaghara si otú a gbakọọ hà nhata ma ọ bụ karịa 0.75 in.2 (500 mm2), mgbe ahụ, uru 0.75 in.2 (500 mm2) ga-eji.), na U = ike tensile akọwapụtara, psi (MPa). | ||||||||

Na mgbakwunye na ịgba mbọ hụ na mejupụtara kemịkalụ na akụrụngwa akụrụngwa, a na-eme nnwale hydrostatic n'otu n'otu, a na-eme nnwale flaring na flattening. . Na mgbakwunye, enwere ụfọdụ ihe achọrọ maka microstructure, nha ọka, na oyi akwa decarburization nke ọkpọkọ ígwè emechara.

Ịkwanye ikike: 1000 ton kwa ọnwa kwa ọkwa nke ASTM SA-106 Steel Pipe

Na ngwugwu na igbe osisi siri ike

7-14 ụbọchị ma ọ bụrụ na ngwaahịa, 30-45 ụbọchị na-emepụta

30% nkwụnye ego, 70% L / C ma ọ bụ B / L oyiri ma ọ bụ 100% L / C na anya