[Detuo] ASME SA-106/SA-106M-2015 Carbon ígwè ọkpọkọ

| ọkọlọtọ: ASTM SA106 | Alloy ma ọ bụ bụghị: Ọ bụghị |

| Otu ọkwa: GR.A,GR.B,GR.C wdg | Ngwa: Fluid Pipe |

| Ọkpụrụkpụ: 1 - 100 mm | Ọgwụgwọ dị n'elu: Dị ka ihe ndị ahịa chọrọ |

| Dayameta dị n'èzí (Gburugburu): 10 - 1000 mm | Usoro: Hot Rolled |

| Ogologo: Ogologo ogologo ma ọ bụ ogologo enweghị usoro | Ọgwụgwọ okpomọkụ: Annealing / normalizing |

| Ụdị ngalaba: Gburugburu | Ọkụ Pụrụ Iche: Okpomọkụ dị elu |

| Ebe Mmalite: China | Ojiji: Mwube, Ụgbọ njem mmiri |

| Asambodo: ISO9001:2008 | Nnwale: ECT/CNV/NDT |

Igwe anaghị agba nchara maka ọrụ okpomọkụ dị elu ASTM A106, dabara maka oke okpomọkụ

Ọkwa nke igwe nrụpụta carbon dị elu: GR.A, GR.B, GR.C

| Nhazi, ( | |||

| Ọkwa A | Ọkwa B | Ọkwa C | |

| Carbon, max | 0.25A | 0.3B | 0.35B |

| Manganese | 0.27-0.93 | 0.29-1.06 | 0.29-1.06 |

| Phosphorus, max | 0,035 | 0,035 | 0,035 |

| Sulfur, max | 0,035 | 0,035 | 0,035 |

| Silikoni, min | 0.10 | 0.10 | 0.10 |

| Chrome, maxC | 0.40 | 0.40 | 0.40 |

| Ọla kọpa, maxC | 0.40 | 0.40 | 0.40 |

| Molybdenum, maxC | 0.15 | 0.15 | 0.15 |

| Nickel, maxC | 0.40 | 0.40 | 0.40 |

| Vanadium, maxC | 0.08 | 0.08 | 0.08 |

| A Maka mbelata ọ bụla nke 0.01% n'okpuru oke carbon akọwapụtara, mmụba nke 0.06% manganese karịa nke akọwapụtara ka a ga-ahapụ ruo oke nke 1.35%. | |||

| B Ọ gwụla ma onye zụrụ ya akọwapụtaghị ya, maka mbelata ọ bụla nke 0.01% n'okpuru oke carbon a kapịrị ọnụ, mmụba nke 0.06% manganese karịa nke akọwapụtara ka a ga-ahapụ ruo oke 1.65%. | |||

| C ihe ise a jikọtara agaghị agafe 1%. | |||

| Ọkwa A | Ọkwa B | Ọkwa C | ||||||

| Ike tensile, min, psi(MPa) | 48 000 (330) | 60000 (415) | 70000 (485) | |||||

| Ike mpụta, min, psi(MPa) | 30000 (205) | 35 000 (240) | 40000 (275) | |||||

| Ogologo ogologo | Transverse | Ogologo ogologo | Transverse | Ogologo ogologo | Transverse | |||

| Mgbatị n'ime inch 2 (50 mm), nkeji, % Basic kacha nta elongation transverse warara ule, na niile obere nha nwalere na zuru ngalaba | 35 | 25 | 30 | 16.5 | 30 | 16.5 | ||

| Mgbe ọkọlọtọ gburugburu 2-in. (50-mm) a na-eji ihe nlere anya ogologo nlele | 28 | 20 | 22 | 12 | 20 | 12 | ||

| Maka ule eriri ogologo ogologo | A | A | A | |||||

| Maka ule ntụgharị ntụgharị, mwepu maka 1/32-in ọ bụla. (0.8-mm) mbelata nke mgbidi dị n'okpuru 5/16 inch (7.9 mm) site na ntinye kacha nta nke kacha nta nke pasent ndị a ga-eme. | 1.25 | 1.00 | 1.00 | |||||

| A ga-ekpebi elongation kacha nta na inch 2 (50 mm) site na nha nha ndị a: | ||||||||

| e=625000A 0.2 / U 0.9 | ||||||||

| maka nkeji inch-paụnd, na | ||||||||

| e=1940A 0.2 / U 0.9 | ||||||||

| maka nkeji SI, | ||||||||

| ebe: e = elongation kacha nta na 2 in. (50 mm), %, gbachie na 0.5% kacha nso, A = mpaghara obe nke ihe nlere ule erughị ala, in.2 (mm2), dabere na nke akọwapụtara n'èzí ma ọ bụ n'ọnụ ọnụ nke akọwapụtara n'èzí dayameta ma ọ bụ obosara ihe atụ na ọkpụrụkpụ mgbidi akọwapụtara, gbachie na 0.01 in.2 (1 mm2) kacha nso. . (Ọ bụrụ na mpaghara si otú a gbakọọ hà nhata ma ọ bụ karịa 0.75 in.2 (500 mm2), mgbe ahụ, uru 0.75 in.2 (500 mm2) ga-eji.), na U = ike tensile akọwapụtara, psi (MPa). | ||||||||

Na mgbakwunye na ịgba mbọ hụ na mejupụtara kemịkalụ na akụrụngwa akụrụngwa, a na-eme nnwale hydrostatic n'otu n'otu, a na-eme nnwale flaring na flattening. . Na mgbakwunye, enwere ụfọdụ ihe achọrọ maka microstructure, nha ọka, na oyi akwa decarburization nke ọkpọkọ ígwè emechara.

Ịkwanye ikike: 1000 ton kwa ọnwa kwa ọkwa nke ASTM SA-106 Steel Pipe

Na ngwugwu na igbe osisi siri ike

7-14 ụbọchị ma ọ bụrụ na ngwaahịa, 30-45 ụbọchị na-emepụta

30% nkwụnye ego, 70% L / C ma ọ bụ B / L oyiri ma ọ bụ 100% L / C na anya

Dee ozi gị ebe a ziga anyị ya

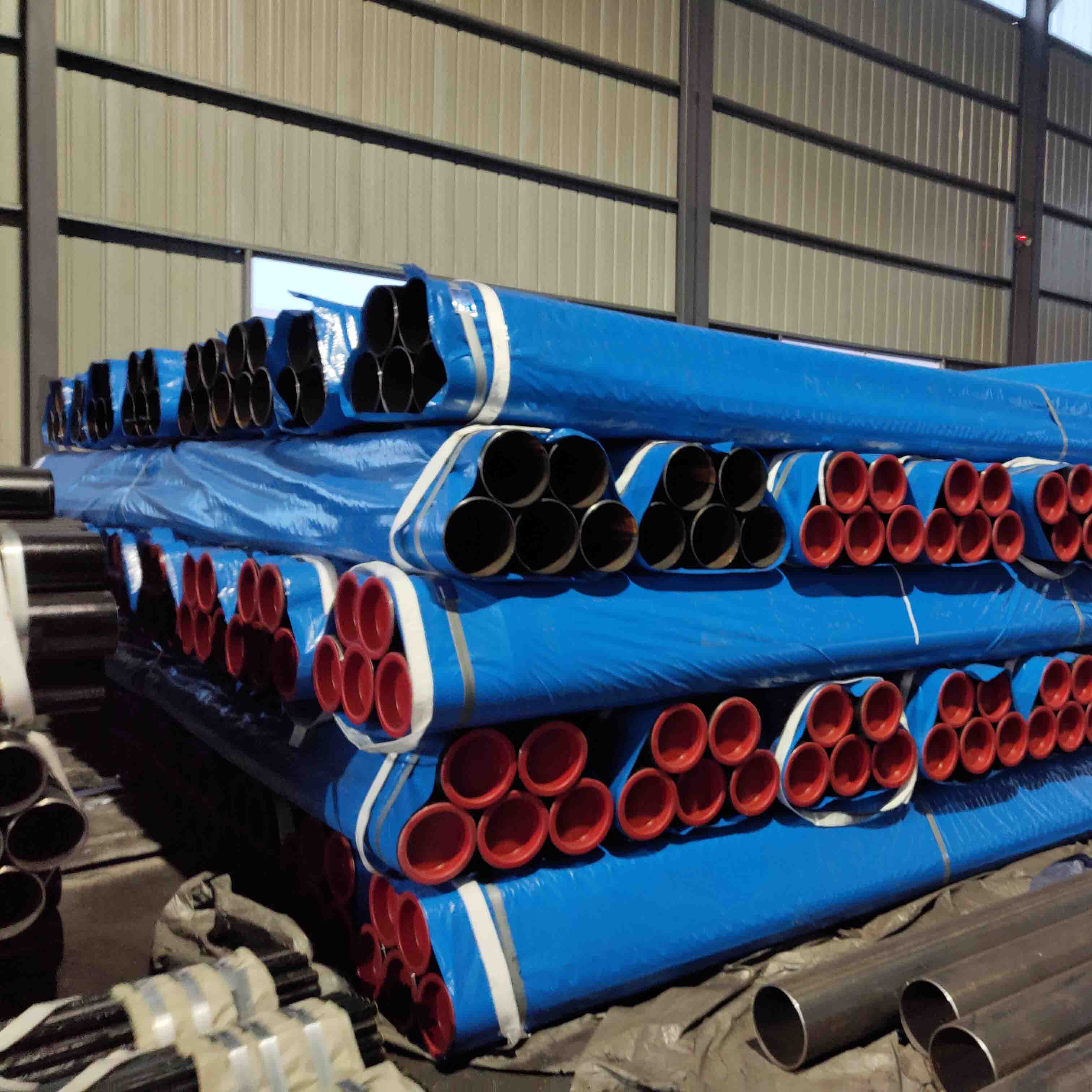

![[Detuo] ASME SA-106/SA-106M-2015 Carbon steel anwụrụ egosipụtara](http://www.sanonpipe.com/uploads/106B1.png)

![[Detuo] ASME SA-106/SA-106M-2015 Carbon ígwè ọkpọkọ](http://www.sanonpipe.com/uploads/106B1-300x300.png)

![[Detuo] ASME SA-106/SA-106M-2015 Carbon ígwè ọkpọkọ](http://www.sanonpipe.com/uploads/8d9d4c2f13-300x300.jpg)

![[Detuo] ASME SA-106/SA-106M-2015 Carbon ígwè ọkpọkọ](http://www.sanonpipe.com/uploads/419ff6d63-300x300.jpg)