Galvanized Steel Pipe

Ụlọ ọrụ anyị na-ahụ maka mbupụ ọkpọkọ na-enweghị nkebigalvanized ọkpọkọ, Ọkpụkpọ galvanized enweghị nkebi, SMLS galvanized ọkpọkọ, Ọkụ galvanized WELDED.

Kedu ihe dị iche n'etiti galvanized na-ekpo ọkụ na oyi galvanized?

Galvanizing na-ekpo ọkụ na-ekpo ọkụ na oyi galvanized dị iche:

1. Galvanizing, makwaara dị ka na-ekpo ọkụ itinye galvanized, ọ bụ ingot gbazee na elu okpomọkụ, a ọnụ ọgụgụ nke emeju ihe na ebe, tinye galvanized metal Ọdịdị oghere, na metal akụrụngwa na a oyi akwa nke zinc mkpuchi . Uru nke na-ekpo ọkụ-mikpu galvanizing corrosion nke ike ya, adhesion na hardness nke zinc mkpuchi ka mma.

"Oyi plated" ma ọ bụ "plating", ntụgharị zinc nnu ngwọta site electrolysis, na plating na mkpuchi, n'ozuzu enweghị kpo oku, obere ego nke zinc, mmiri gburugburu dị mfe ịdapụ.

2. Hot itinye galvanized (galvanizing)

Galvanizing na-ekpo ọkụ bụ ọgwụgwọ kemịkalụ, bụ mmeghachi omume electrochemical.

Oyi galvanizing bụ anụ ahụ adreesị, naanị ahịhịa n'elu oyi akwa nke zinc, zinc oyi akwa dị mfe ịdapụ. Ewu na ojiji nke na-ekpo ọkụ itinye galvanizing.

Na-aga n'ihu na-ekpo ọkụ itinye galvanizing usoro: ígwè → kpo oku → jụrụ na okpomọkụ galvanized galvanized → jụrụ →

Oyi galvanized zinc bụ naanị 10-50g / m2, ya onwe corrosion eguzogide karịa na-ekpo ọkụ itinye galvanized a otutu ihe dị iche. Galvanized site na ọnụ ahịa dị ọnụ ala karịa.

Hot itinye galvanized ígwè ahụ na-ekpo ọkụ itinye galvanized elu n'okpuru ọnọdụ nke adhesion ike, ọ dịghị mfe ịdapụ, ọ bụ ezie na e nwere ọkụ itinye.galvanized ọkpọkọcorrosion onu, ma na a nnọọ ogologo oge izute teknuzu, ike chọrọ.

3. Teknụzụ dị iche iche

Nke mbụ, bụ ihe dị iche n'etiti usoro: na-ekpo ọkụ-mikpuo galvanizing bụ workpiece degreasing, pickling, dipping, ihicha mmiri mmiri imikpu na gbazee zinc ụfọdụ oge, nwere ike welie.

A makwaara dị ka electro-galvanized oyi galvanizing, bụ iji electrolysis ngwaọrụ-arụ ọrụ ibe site degreasing, pickling Efrata biputere n'ime zinc nnu ngwọta, na jikọọ na anode electrolysis ngwá; na ebe gafee akụkụ nke zinc efere jikọọ na electrolysis ngwá mma, ike na, ojiji nke ugbu a si cathode na anode nke directional ije nke workpiece ga-edebe na a oyi akwa nke zinc.

Zinc okokụre ihe dị iche: ọ dịghị oyi galvanized na-ekpo ọkụ-mikpu galvanizing siri na-egbuke egbuke anya, ma ọkpụrụkpụ nke zinc mkpuchi nke oyi galvanizing akụkụ nke na-ekpo ọkụ-mikpu galvanizing bụ ugboro ole na ole. Galvanized corrosion eguzogide bụkwa ọtụtụ ugboro.

Nchịkọta

Ngwa

A na-eji ya eme ihe maka ike na akụkụ nrụgide, yana maka ebumnuche izugbe uzuoku, mmiri, gas na ọkpọkọ ikuku.

Isi ọkwa

GR.A, GR.B

Ngwakọta kemịkalụ

| Ọkwa | Akụkụ% ≤ | ||||||||

| C | Mn | P | S | KuA | NiA | CrA | MoA | VA | |

| Ụdị S (paịpụ enweghị nkebi) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0,045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0,045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Ụdị E (Nguzogide welded ọkpọkọ) | |||||||||

| GR.A | 0.25B | 0.95 | 0.05 | 0,045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0,045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Ụdị F (Ọkụ Welded Pipe) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0,045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Nchikota nke ihe ise a agaghị agafe 1.00%.

B Maka 0.01% ọ bụla na-ebelata na ọdịnaya carbon kachasị elu, a na-ahapụ ọdịnaya manganese kachasị elu site na 0.06%, mana nke kachasị enweghị ike gafere 1.35%.

C Mbelata 0.01% ọ bụla na ọdịnaya carbon kacha elu ga-ekwe ka ọdịnaya manganese kachasị elu na-abawanye site na 0.06%, mana nke kachasị agaghị agafe 1.65%.

Ngwongwo igwe

| ihe | GR.A | GR.B |

| ike tensile, ≥, psi [MPa] Ike Mpụta, ≥, psi [MPa] Nlele 2in. ma ọ bụ 50mm elongation | 48 000 [330]30 000 [205] A, B | 60000 [415]35 000 [240]A,B |

A Nke kacha nta elongation nke nlele ogologo 2in. (50mm) ga-ekpebi site na usoro a:

e=625000(1940)A0.2/U0.9

e = kacha nta elongation nke nlele 2in. (50mm), pasent gbakọrọ na 0.5% kacha nso;

A = A gbakọọ dabere na dayameta mpụta akọwapụtara nke tube n'ọnụ ma ọ bụ obosara ọnụ nke ihe nlere anya na oke mgbidi ya akọwapụtara, wee gbachie ya na mpaghara obe kacha nso nke ihe nlere anya nke 0.01 in.2 (1 mm2). ma e jiri ya tụnyere 0.75in.2 (500mm2), nke ọ bụla dị ntakịrị.

U = a kapịrị ọnụ kacha nta ike tensile, psi (MPa).

B Maka nchikota dị iche iche nke nha dị iche iche nke ụdị ule nlegharị anya na ike mkpirisi nke kacha nta, egosiri elongation kacha nta achọrọ na Tebụl X4.1 ma ọ bụ Tebụl X4.2, dịka ọdabara ya si dị.

Achọrọ nnwale

Nnwale tensile, ule mgbada, nnwale hydrostatic, ule eletrik na-adịghị emebi emebi nke welds.

Ikike inye

Ikike ịnye: 2000 tọn kwa ọnwa kwa ọkwa nke ASTM A53/A53M-2012 Steel Pipe

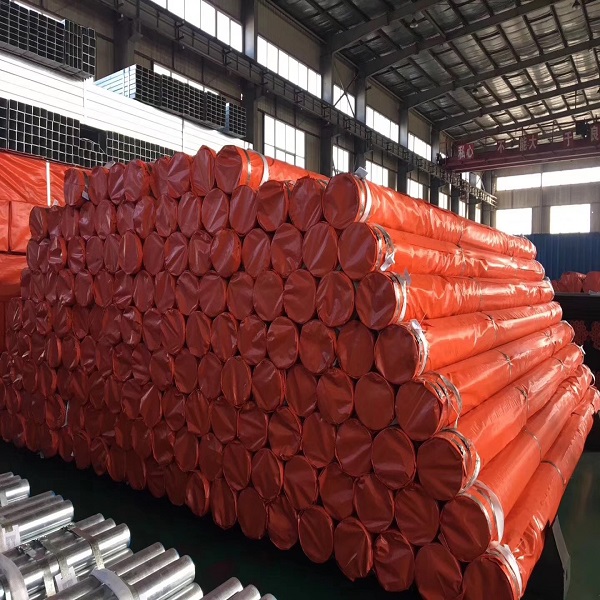

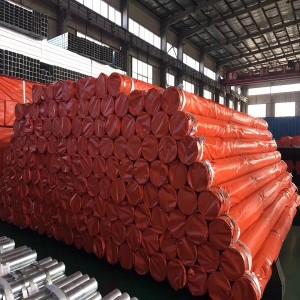

Nkwakọ ngwaahịa

Na ngwugwu na igbe osisi siri ike

Nnyefe

7-14 ụbọchị ma ọ bụrụ na ngwaahịa, 30-45 ụbọchị na-emepụta

Ịkwụ ụgwọ

30% nkwụnye ego, 70% L / C ma ọ bụ B / L oyiri ma ọ bụ 100% L / C na anya