15Mo3 (15MoG): Ọ bụ ọkpọkọ ígwè na ọkọlọtọ DIN17175. Ọ bụ obere dayameta carbon molybdenum ígwè tube maka ji esi mmiri ọkụ na superheater, na a pearlescent ụdị ọkụ ọkụ ígwè. N'afọ 1995, a tụgharịrị yaGB5310ma kpọọ aha 15MoG. Ngwakọta kemịkalụ ya dị mfe, mana ọ nwere molybdenum, yabụ na ọ nwere ike thermal ka mma karịa carbon steel ka ọ na-ejigide otu usoro arụmọrụ dị ka carbon steel. N'ihi arụmọrụ ya dị mma, ọnụ ala dị ọnụ ala, ejirila ya mee ihe n'ụwa niile. Otú ọ dị, ígwè nwere ọchịchọ nke graphitization mgbe ogologo oge na-arụ ọrụ na elu okpomọkụ, n'ihi ya, ya na-arụ ọrụ okpomọkụ kwesịrị ịchịkwa n'okpuru 510 ℃, na ego nke Al agbakwunyere na agbaze kwesịrị nanị ịchịkwa na-egbu oge na graphitization usoro. A na-eji tube nchara a na-ejikarị eme ihe maka ọkụ ọkụ dị ala yana igwe ọkụ ọkụ dị ala. Okpomọkụ mgbidi dị n'okpuru 510 ℃. Ihe mejupụtara kemịkalụ ya C0.12-0.20, SI0.10-0.35, MN0.40-0.80, S≤0.035, P≤0.035, MO0.25-0.35; Ọkwa ike nkịtị σs≥270-285, σb≥450-600 MPa; Plastic delta 22 ma ọ bụ karịa.

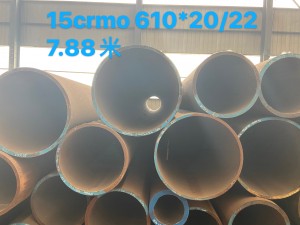

15CrMoG:GB5310-95 ígwè (nke kwekọrọ na 1CR-1 / 2Mo na 11 / 4CR-1 / 2MO-Si ígwè a na-ejikarị eme ihe n'ụwa), ọdịnaya chromium ya dị elu karịa ígwè 12CrMo, ya mere ọ nwere ike ọkụ dị elu na 500-550 ℃. Mgbe okpomọkụ karịrị 550 ℃, thermal ike nke ígwè na-ebelata nke ukwuu. Mgbe a na-arụ ọrụ ya ogologo oge na 500-550 ℃, graphitization anaghị eme, ma carbide spheroidization na alloying element redistribution eme, nke na-eduga ná mbelata nke thermal ike nke ígwè. The ígwè nwere ezigbo iguzogide ntụrụndụ na 450 ℃. Ya ọkpọkọ ime na ịgbado ọkụ usoro arụmọrụ dị mma. Ọ na-tumadi ji dị ka elu na ọkara mgbali uzuoku conduit na njikọ igbe na uzuoku oke n'okpuru 550 ℃, superheater tube na mgbidi okpomọkụ n'okpuru 560 ℃, wdg Ya chemical mejupụtara C0.12-0.18, Si0.17-0.37, MN0.40-0.70, S≤030.0.0.0.0. CR0.80-1.10, MO0.40-0.55; N'okpuru ọnọdụ iwe ọkụ nkịtị, ọkwa ike σs≥235, σb≥440-640 MPa; Plastic delta p21.

T22 (P22), 12Cr2MoG: T22 (P22) bụASME SA213 (SA335) koodu ihe, nke gụnyere naGB5310-95. Na usoro nchara CR-Mo, arụ ọrụ ike ọkụ ya dị oke elu, otu ike na-adịgide adịgide na nrụgide a na-anabata karịa 9CR-1Mo steel ọbụna karịa, yabụ a na-eji ya na ike thermal mba ofesi, ike nuklia na ụgbọ mmiri nrụgide. Agbanyeghị, akụ na ụba teknụzụ ya dị ala karịa 12Cr1MoV anyị, yabụ na-eji obere ya eme ihe n'ichepụta ọkụ ọkụ ọkụ ụlọ. Jiri naanị mgbe achọrọ ya (karịsịa mgbe emebere ya na arụpụtara ya dịka koodu ASME siri dị). Igwe anaghị emetụ n'ahụ na ọgwụgwọ okpomọkụ ma nwee nnukwu plasticity na-adịgide adịgide na ezigbo ịgbado ọkụ. T22 obere dayameta tube bụ tumadi ji dị ka metal mgbidi okpomọkụ n'okpuru 580 ℃ superheater na reheater kpo oku elu tube, wdg.P22nnukwu dayameta tube na-bụ-eji na metal mgbidi okpomọkụ abụghị ihe karịrị 565 ℃ superheater / reheater njikọ njikọ na isi uzuoku ọkpọkọ. Ihe mejupụtara kemịkalụ ya C≤0.15, Si≤0.50, MN0.30-0.60, S≤0.025, P≤0.025, CR1.90-2.60, MO0.87-1.13; N'okpuru ọnọdụ iwe ọkụ nkịtị, ọkwa ike σs≥280, σb≥450-600 MPa; Plastic delta 20 ma ọ bụ karịa.

12Cr1MoVG:GB5310-95 nano ọkọlọtọ ígwè, bụ anụ ụlọ elu mgbali, ultra elu mgbali, subcritical ike osisi ji esi mmiri ọkụ superheater, collection igbe na isi uzuoku conduit ọtụtụ ebe eji ígwè. The chemical mejupụtara na n'ibu Njirimara nke 12Cr1MoV efere bụ ihu ọma otu. Ngwakọta kemịkalụ ya dị mfe, mkpokọta alloy dị ihe na-erughị 2%, maka obere carbon, ụdị alloy pearlescent dị ala nke igwe na-ekpo ọkụ. Vanadium nwere ike ịmepụta VC carbide kwụsiri ike na carbon, nke nwere ike ime ka chromium na molybdenum dị nchara dị mma na ferrite, wee belata mbufe chromium na molybdenum site na ferrite gaa na carbide, nke mere na igwe kwụsiri ike na oke okpomọkụ. Ngụkọta ego nke alloyed ọcha na nke a ígwè bụ nanị ọkara nke 2.25 CR-1Mo ígwè ọtụtụ ebe na mba ọzọ, ma inogide ike na 580 ℃ na 100,000 h bụ 40% elu karịa nke ikpeazụ. Ọzọkwa, usoro mmepụta dị mfe na ịrụ ọrụ ịgbado ọkụ dị mma. Ọ bụrụhaala na usoro ọgwụgwọ okpomọkụ siri ike, enwere ike imeju arụmọrụ zuru oke na ike ọkụ. N'ezie ọrụ nke ike ọdụ na-egosi na 12Cr1MoV isi uzuoku pipeline ka nwere ike iji mgbe nchekwa ọrụ na 540 ℃ maka 100,000 awa. A na-ejikarị tube nke nwere dayameta dị ka igbe nchịkọta na isi ikuku uzuoku nke oke uzuoku n'okpuru 565 ℃, a na-ejikwa obere tube dị dayameta maka ikpo ọkụ ọkụ elu tube nke mgbidi metal dị n'okpuru 580 ℃.

12Cr2MoWVTiB (G102):gb5310-95 na ígwè, n'ihi na China onwe mmepe na 1960, obere carbon, ala alloy (obere ego nke di iche iche) Bainite ụdị ọkụ ike ígwè, si 1970s e gụnyere na Ministry of Metallurgical Industry ọkọlọtọ YB529-70 na ugbu a na mba ọkọlọtọ, na njedebe nke 1980 na ígwè site na Machinery ike na Ministry of Metallu eletriki nke Ministry of Metallu. njirimara. The ígwè nwere ezi keukwu n'ibu Njirimara, na ya thermal ike na ọrụ okpomọkụ dị elu karịa nke yiri steels ná mba ọzọ, na-eru larịị nke ụfọdụ chromium-nickel austenitic steels na 620 ℃. Nke a bụ n'ihi na ígwè nwere ọtụtụ ụdị alloying ọcha, ma gbakwunyere iji melite oxidation iguzogide ihe ndị dị ka Cr, Si, otú kacha ọrụ okpomọkụ nwere ike iru 620 ℃. Ọrụ n'ezie nke ọdụ ike na-egosi na nhazi na ihe onwunwe nke ọkpọkọ ígwè adịghị agbanwe nke ukwuu mgbe arụ ọrụ ogologo oge gasịrị. A na-ejikarị ya dị ka tube na-ekpo ọkụ na reheater tube maka igwe ọkụ ọkụ dị elu nke nwere okpomọkụ metal ≤620 ℃. Ihe mejupụtara kemịkalụ ya C0.08-0.15, Si0.45-0.75, MN0.45-0.65, S≤0.030, P≤0.030, CR1.60-2.10, MO0.50-0.65, V0.28-0.42,0.5.0.08-W. B0.002-0.008; N'okpuru ọnọdụ iwe ọkụ nkịtị, ọkwa ike σs≥345, σb≥540-735 MPa; Plastic delta p18.

Sa-213t91 (335P91): Nọmba igwe n'imeASME SA-213(335) ọkọlọtọ. Emepụtara site na Rubber Ridge National Laboratory of the United States of America, eji na nuklia ike (enwere ike na-eji na ndị ọzọ akụkụ) elu okpomọkụ mkpakọ components nke ihe onwunwe, na ígwè dabeere na T9 (9CR-1MO) ígwè, na njedebe nke carbon ọdịnaya, ọzọ nditịm ịchịkwa ọdịnaya nke P na S na ndị ọzọ fọdụrụnụ ọcha n'otu oge ahụ, A ọhụrụ ụdị ferritic okpomọkụ na-eguzogide alloy ígwè e hiwere site traktị ọla kọpa. 0.030-0.070% N, 0.18-0.25% V na 0.06-0.10% Nb iji mezuo ihe ndị a chọrọ maka nhazi ọka. Ọ bụASME SA-213kọlụm ọkọlọtọ ígwè, nke a transplanted n'imeGB5310ọkọlọtọ na 1995 na ọkwa bụ 10Cr9Mo1VNb. Edepụtara ọkọlọtọ mba ụwa ISO/DIS9399-2 dị ka X10 CRMOVNB9-1.

N'ihi ọdịnaya chromium dị elu (9%), nguzogide oxidation, nguzogide corrosion, ike okpomọkụ dị elu na ọdịdị na-abụghị nke graphitization dị mma karịa nke ígwè alloy dị ala. Molybdenum (1%) na-eme ka ike dị elu na-ekpo ọkụ ma na-egbochi ọchịchọ na-ekpo ọkụ nke ígwè chromium. Tụnyere T9, na ịgbado ọkụ na thermal ike ọgwụgwụ Njirimara na-mma, na inogide ike na 600 ℃ bụ ugboro atọ na nke ikpeazụ, na magburu onwe elu-okpomọkụ corrosion eguzogide nke T9 (9CR-1Mo) ígwè na-nọgidere. E jiri ya tụnyere austenitic igwe anaghị agba nchara, ọnụọgụ mgbasawanye dị ntakịrị, conductivity thermal dị mma, ma nwee ike dị elu dị elu (dịka na TP304 austenitic steel ratio, ruo mgbe okpomọkụ siri ike bụ 625 ℃, nha nrụgide okpomọkụ bụ 607 ℃). Ya mere, ọ nwere mma keukwu n'ibu Njirimara, anụ Ọdịdị na Njirimara tupu na mgbe ịka nká, ezi ịgbado ọkụ na usoro Njirimara, elu inogide ike na ọxịdashọn-eguzogide. A na-eji ya eme ihe maka igwe na-ekpo ọkụ na reheater nwere okpomọkụ metal ≤650 ℃ na mmiri ọkụ. Ihe mejupụtara kemịkalụ ya C0.08-0.12, Si0.20-0.50, MN0.30-0.60, S≤0.010, P≤0.020, CR8.00-9.50, MO0.85-1.05, V0.18-0.25, Al0.0.0.0.0.1 N0.03-0.07; N'okpuru ọnọdụ iwe ọkụ nkịtị, ọkwa ike σs≥415, σb≥585 MPa; Plastic delta 20 ma ọ bụ karịa.

Oge nzipu: Sep-07-2022