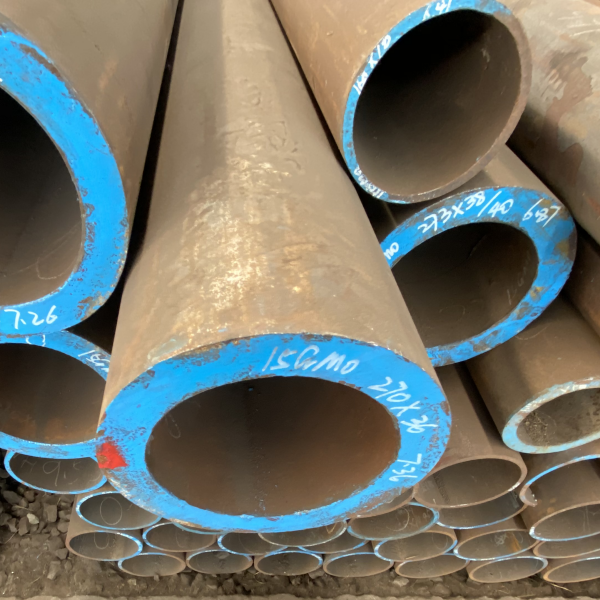

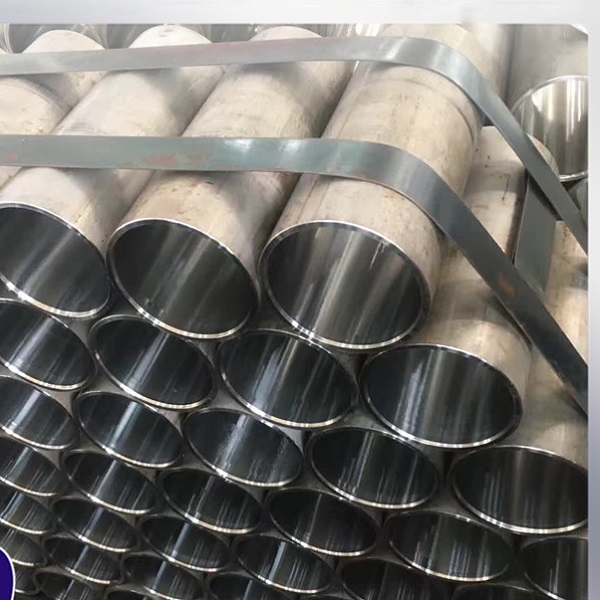

tubes igwe anaghị agba nchara maka mgbawa mmanụ, GB9948-2006, Sanon Pipe

| Ọkọlọtọ: GB9948-2006 | Ọgwụgwọ okpomọkụ: Annealing / normalizing / Tempering |

| Otu ọkwa: 10, 12CrMo, 15CrMo, 07Crl9Nil0, wdg. | Dayameta dị n'èzí (Gburugburu): 10 - 1000 mm |

| Ọkpụrụkpụ: 1 - 100 mm | Ngwa: tubes mgbanwe okpomọkụ |

| Dayameta dị n'èzí (Gburugburu): 10 - 1000 mm | Ọgwụgwọ dị n'elu: Dị ka ihe ndị ahịa chọrọ |

| Ogologo: Ogologo ogologo ma ọ bụ ogologo enweghị usoro | Usoro: Hot Rolled |

| Ụdị ngalaba: Gburugburu | Ọkụ Pụrụ Iche: Ọkụ Mgbidi |

| Ebe Mmalite: China | Ojiji: ọkpọkọ mgbanwe okpomọkụ |

| Asambodo: ISO9001:2008 | Nnwale:UT/MT |

Igwe anaghị agba nchara maka mgbawa mmanụ ala na-adabara na ọkpọkọ igwe anaghị agba nchara maka ọkpọ ọkụ, ọkpọkọ mgbanwe okpomọkụ na ọkpọkọ nrụgide na ụlọ ọrụ petrochemical.

High mma carbon structural ígwè akara ule bụ 20g, 20mng na 25mng.

Alloy structural steel akara ule: 15mog, 20mog, 12cmog

15CrMoG, 12Cr2MoG, 12CrMoVG, wdg

Ọkwa nke igwe nrụpụta carbon dị elu: 10 #,20#

High mma carbon structural ígwè akara ule: 20g, 20mng na 25mng

Alloy structural ígwè akara ule: 15mog, 20mog, 12crmog, 15CrMoG, 12Cr2MoG, wdg

| No | Ọkwa | Akụkụ kemịkalụ% | |||||||||||

| C | Si | Mn | Cr | Mo | Ni | Nb | Ti | V | Cu | P | S | ||

| ≤ | |||||||||||||

| Steel Structural Carbon dị elu | 10 | 0. 07-0.13 | 0.17-0. 37 | 0.35-0.65 | <0.15 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0.015 |

| 20 | 0.17-0. 23 | 0.17-0. 37 | 0.35-0.65 | <0. 25 | <0.15 | <0. 25 | - | - | <0. 08 | <0. 20 | 0.025 | 0.015 | |

| Alloy Structural Steel | 12CrMo | 0. 08-0.15 | 0.17-0.37 | 0. 40-0. 70 | 0. 40-0. 70 | 0. 40 -0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 |

| 15CrMo | 0.12-0.18 | 0.17-0. 37 | 0.40-0. 70 | 0. 80-1.1 | 0. 40-0.55 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 | |

| 12CrlMo | 0. 08 -0.15 | 0.50-1. 00 | 0. 30-0.6 | 1.00-1. 50 | 0.45-0.65 | <0. 30 | - | - | - | <0, 20 | 0.025 | 0.015 | |

| 12CrlMoV | 0. 08-0.15 | 0.17-0. 37 | 0. 40-0. 70 | 0.90-1.2 | 0. 25 -0.35 | <0. 30 | - | - | 0.15-0. 30 | <0. 20 | 0.025 | 0.010 | |

| 12Cr2Mo | 0.08-0.15 | <0. 50 | 0. 40-0. 60 | 2. 00-2. 50 | 0. 90-1.13 | <0. 30 | - | - | 一 | <0. 20 | 0.025 | 0.015 | |

| 12Cr5MoI | <0.15 | <0. 50 | 0.30-0.6 | 4. 00-6 | 0. 45-0. 60 | <0. 60 | - | - | <0. 20 | 0.025 | 0.015 | ||

| 12Cr5MoNT | |||||||||||||

| 12Cr9MoI | <0.15 | 0. 25-1. 00 | 0. 30-0. 60 | 8.00-10. 00 | 0. 90-1.1 | <0. 60 | - | - | - | <0. 20 | 0.025 | 0, 015 | |

| 12Cr9MoNT | |||||||||||||

| Igwe anaghị agba nchara na-eguzogide okpomọkụ | 07Crl9Nil0 | 0. 04-0.1 | <1. 00 | <2. 00 | 18. 00-20. 00 | - | 8. 00-11 | - | - | - | - | 0.030 | 0.015 |

| 07Crl8NillNb | 0. 04-0.1 | <1. 00 | <2. 00 | 17. 00-19. 00 | - | 9.00-12. 00 | 8C-1.1 | - | - | - | 0.030 | 0.015 | |

| 07Crl9NillTi | 0. 04-0.1 | <0. 75 | <2. 00 | 17.00-20. 00 | - | 9. 00-13. 00 | - | 4C-0. 60 | 一 | 一 | 0.03 | 0.015 | |

| 022Crl7Nil2Mo2 | <0. 030 | <1. 00 | <2. 00 | 16. 00-18. 00 | 2. 00-3. 00 | 10.00 -14. 00 | - | 一 | 一 | - | 0.03 | 0.015 | |

| Mba | Mgbatị MPa | Mmụba MPa | Na-agbatị mgbe agbajiri agbaji A/% | Ike mbịara mbịambịa kv2/j | Nọmba hardness brinell | ||

| Eserese | transver | Eserese | transver | ||||

| ọ bụghị ihe na-erughị | ọ bụghị karịa | ||||||

| 10 | 335-475 | 205 | 25 | 23 | 40 | 27 | |

| 20 | 410-550 | 245 | 24 | 22 | 40 | 27 | |

| 12CrMo | 410-560 | 205 | 21 | 19 | 40 | 27 | 156 HBW |

| 15CrMo | 440-640 | 295 | 21 | 19 | 40 | 27 | 170 HBW |

| 12CrlMo | 415-560 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12CrlMoV | 470-640 | 255 | 21 | 19 | 40 | 27 | 179 HBW |

| 12Cr2Mo | 450-600 | 280 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoI | 415-590 | 205 | 22 | 20 | 40 | 27 | 163 HBW |

| 12Cr5MoNT | 480-640 | 280 | 20 | 18 | 40 | 27 | - |

| 12Cr9MoI | 460-640 | 210 | 20 | 18 | 40 | 27 | 179 HBW |

| 12Cr9MoNT | 590-740 | 390 | 18 | 16 | 40 | 27 | |

| O7Crl9Nilo | 2520 | 205 | 35 | 187 HBW | |||

| 07Crl8NillNb | >520 | 205 | 35 | - | 187 HBW | ||

| 07Crl9NillTi | >520 | 205 | 35 | - | - | 187 HBW | |

| 022Crl7Nil2Mo2 | > 485 | 170 | 35 | 一 | - | 187 HBW | |

| N'ihi na ígwè na mgbidi ọkpụrụkpụ na-erughị 5mm tube emela ike siri ike nnwale | |||||||

Nnwale hydraulic

A ga-eme ule hydraulic maka ọkpọkọ ígwè n'otu n'otu. Nrụgide ule kachasị bụ 20 MPa. N'okpuru nrụgide ule, oge nkwụsi ike agaghị abụ ihe na-erughị 10 s, a naghị anabata nkwụsị nke ọkpọkọ ígwè.

Nnwale ire ụtọ

A ga-eme ule nlegharị anya maka ọkpọkọ ígwè nwere dayameta dị n'èzí karịa 22 mm

Nnwale ọkụ

Carbon structural steel dị elu na igwe anaghị agba nchara (okpomọkụ na-eguzogide) ọkpọkọ nchara na dayameta dị n'èzí nke na-erughị 76 mm na mgbidi nke na-erughị 8 mm ga-adị n'okpuru ule ịgbasa. A ga-eme ule na-enwu ọkụ na ụlọ okpomọkụ. The elu dayameta flaring ọnụego nke sample mgbe top isi taper bụ 60% nke flaring ga-ezute chọrọ nke table 7. Ọ dịghị cracks ma ọ bụ cracks na-ekwe na sample mgbe flaring. Dị ka ihe ndị chọrọ nke onye na-achọ ihe si dị ma kwuo na nkwekọrịta ahụ, a pụkwara iji ígwè nhazi nke alloy mee ihe maka ịgbasa ule.

teste adịghị emebi emebi

Ọkpụkpụ ígwè ga-adị n'okpuru nchọpụta ntụpọ ultrasonic n'otu n'otu dị ka usoro GB / T 5777-2008 si dị. Dị ka ihe ndị chọrọ chọrọ, enwere ike ịgbakwunye ule ndị ọzọ na-adịghị emebi emebi mgbe mkparịta ụka dị n'etiti onye na-ebubata ya na onye na-achọ ya ma gosipụta ya na nkwekọrịta.

Nnwale corrosion intergranular

A ga-eme ule corrosion intergranular maka ọkpọkọ igwe anaghị agba nchara (ọkụ na-eguzogide). Usoro nnwale ahụ ga-adị n'usoro iwu nke Chinese E na GB / T 4334-2008, a naghị anabata ọdịdị corrosion intergranular mgbe ule ahụ gasịrị.

Mgbe mkparịta ụka dị n'etiti onye na-ebubata ya na onye na-achọ ya, ma depụta ya na nkwekọrịta ahụ, onye na-achọ ya nwere ike ịkọwapụta ụzọ ule corrosion ndị ọzọ.

Mmanụ, petrochemical, mmiri ọkụ dị elu, ojiji pụrụ iche nke tube ji esi mmiri ọkụ na-enweghị nkebi, tube nchara na-enweghị nkebi ala na mmanụ enweghị nkebi.

Ngwakọta kemịkalụ

| ika | Akụkụ kemịkalụ (%) | ||||||||

| C | Mn | Si | Cr | Mo | Ni | Nb+Ta | S | P | |

| 15CrMo | 0.12-0.18 | 0.40-0.70 | 0.17-0.37 | 0.80-1.10 | 0.40-0.55 | ≤0.30 | _ | ≤0.035 | ≤0.035 |

Ngwongwo igwe

| ika | Mgbatị MPa | Mmụba MPa | Elongation (%) |

| 15CrMo | 440-640 | 295 | 22 |