Ipayipi Lensimbi Eshisayo Yase-China/Ipayipi Lensimbi Elishiselwe, ASTM A53 API 5L

Uhlolojikelele

Kungaba ukuziphendulela kwethu ukwanelisa okuncamelayo futhi sikunikeze ngokufanelekile. Ukwaneliseka kwakho kuwumvuzo wethu omkhulu kunayo yonke. Sibheke phambili ekuhambeleni kwakho ukuze sikhule ngokubambisana. Ngenxa yemizamo yethu, izimpahla zethu zizuze ukwethenjwa ngabathengi futhi zithengiswa kakhulu ngokulinganayo lapha naphesheya. Imboni yethu iphikelela kumgomo othi "Ikhwalithi Yokuqala, Ukuthuthukiswa Okusimeme", futhi ithatha "Ibhizinisi Elithembekile, Izinzuzo Ezihlangene" njengomgomo wethu ongathuthukiswa. Wonke amalungu abonga ngobuqotho ngakho konke ukwesekwa kwamakhasimende amadala namasha. Sizoqhubeka nokusebenza kanzima futhi sikunikeze imikhiqizo nesevisi yekhwalithi ephezulu kakhulu.

Mayelana ne-carbon steel eshiselwe nepayipi elingenamthungo, ukuze kukhuliswe ikhono lokumelana nokugqwala, kuzoba khona uhlobo oluthile lokwelapha lwamapayipi. Enye yezinto ezisetshenziswa kakhulu yijazi le-zinc (galvanize). Kunezinhlobo ezimbili zendlela yokwenza i-galvanizing: i-glavanizing ebandayo (i-electrogalvanizing) kanye ne-galvanizing eshisayo. Ngenxa yokuthi inkinga yemvelo, ukucwebezelisa okubandayo kunqunyelwe eShayina, futhi ukugalela amanzi ashisayo nakho akukwazi ukusetshenziswa njengepayipi lokuhambisa amanzi, kodwa kusetshenziswe kabanzi ekucimeni umlilo, ugesi kanye nothelawayeka.

I-Cold galvanizing i-electrogalvanizing, ngenxa yomkhawulo wesu, ijazi le-zinc aliningi, ikakhulukazi ku-10-50g/m2, ngakho-ke, ikhono layo lokumelana nokugqwala lingaphansi kokushisa okushisayo. UMnyango Wezokwakha usuqede ngokusemthethweni ukuqedwa kwamapayipi abandayo anothayela ngobuchwepheshe obubuyela emuva, futhi akuvumelekile ukusebenzisa amapayipi abandayo amapayipi amanzi negesi. Isendlalelo esiphehliwe sepayipi lensimbi elicwengekileyo elibandayo liyisingqimba se-electroplated, futhi isendlalelo se-zinc kanye ne-substrate yepayipi lensimbi zendlalwe ngokuzimela. Isendlalelo se-zinc sincane kakhulu, futhi ungqimba lwe-zinc lumane lunamathele ku-substrate yepayipi yensimbi futhi kulula ukuwa. Ngakho-ke, ukumelana nokugqwala kwayo kubi.

Ungqimba lwe-alloy pipe yepayipi elishisayo lakhiwa ukusabela kwensimbi encibilikisiwe kanye ne-substrate yensimbi, ukuze i-substrate ne-plating layer kuhlanganiswe, futhi ungqimba lokucwenga akulula ukuwa. I-hot dip galvanizing inezinzuzo zokuhlanganisa iyunifomu, ukunamathela okuqinile nempilo ende yesevisi. I-substrate yepayipi lensimbi elidiphu elishisayo elishisayo kanye nesixazululo sokucwenga esincibilikisiwe sibhekana nokusabela okuyinkimbinkimbi ngokomzimba namakhemikhali ukuze kwakhe ungqimba lwengxubevange yensimbi ye-zinc-iron enesakhiwo esihlangene. Isendlalelo se-alloy sihlanganiswe nesendlalelo se-zinc ehlanzekile kanye ne-substrate yepayipi yensimbi, ngakho ukumelana kwayo nokugqwala kunamandla.

Isicelo

Isetshenziselwa Ikakhulukazi izingxenye zamandla nengcindezi, futhi ngenjongo evamile yamapayipi omusi, amanzi, igesi nomoya.

Ibanga Eliyinhloko

G.A, GR.B

Ingxenye Yekhemikhali

| Ibanga | Ingxenye %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (ipayipi elingenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (Ipayipi elishiselwe ukumelana) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo F (Ipayipi Elishiselwe Esithandweni) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isamba salezi zakhi ezinhlanu akufanele sibe ngaphezu kuka-1.00%.

B Kulokho kwehla ngo-0.01% kokuqukethwe okuphezulu kwekhabhoni, okuqukethwe okuphezulu kwe-manganese kuvunyelwe ukukhuphuka ngo-0.06%, kodwa umkhawulo angeke udlule u-1.35%.

C Ukwehla ngakunye ngo-0.01% kokuqukethwe kwekhabhoni ephezulu kuzovumela okuqukethwe okuphezulu kwe-manganese ukuthi kukhuphuke ngo-0.06%, kodwa umkhawulo akumele udlule u-1.65%.

Impahla Mechanical

| into | G.A | GR.B |

| amandla okubamba, ≥, psi [MPa] Amandla Okukhiqiza, ≥, psi [MPa] Gauge 2in.noma 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubude obuncane begeji engu-2in. (50mm) izonqunywa ngefomula elandelayo:

e=625000(1940)A0.2/U0.9

e = ubude obuncane begeji engu-2in. (50mm), iphesenti lifinyezwa ku-0.5% eseduze;

A = Ibalwa ngokuhambisana nobubanzi obushiwo bangaphandle beshubhu lokuzisholo noma ububanzi besampula obuqinile kanye nogqinsi olucacisiwe lodonga, futhi lazungezwa endaweni eseduze yesigaba esiphambanayo yesampula eqinile engu-0.01 in.2 (1 mm2), futhi Iqhathaniswa no-0.75in.2 (500mm2), kuye ngokuthi yikuphi okuncane.

U = amandla amancane aqinile abekiwe, i-psi (MPa).

B Ngokuhlanganiswa okuhlukahlukene kosayizi abahlukene bezibonelo zokuhlolwa kwe-tensile namandla anqunyiwe abekiwe, ubude obuncane obudingekayo buboniswa kuThebula X4.1 noma kuThebula X4.2, ngokuya ngokusebenza kwakho.

Isidingo Sokuhlola

Ukuhlolwa kwe-tensile, ukuhlolwa kokugoba, ukuhlolwa kwe-hydrostatic, ukuhlolwa kukagesi okungonakalisi kwama-welds.

Supply Amandla

Ikhono Lokuhlinzeka: Amathani angu-2000 Ngenyanga Ngebanga ngalinye le-ASTM A53/A53M-2012 Ipayipi Lensimbi

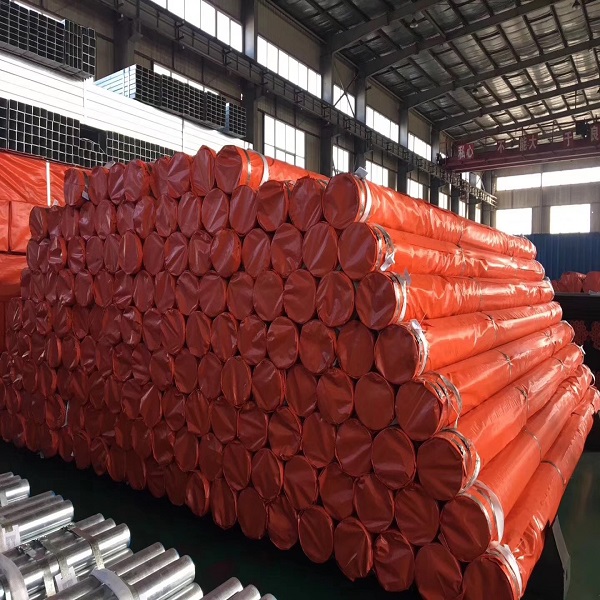

Ukupakisha

Kuyizinqwaba Nasebhokisini Lokhuni Eliqinile

Ukulethwa

Izinsuku ezingu-7-14 uma zisesitokweni, izinsuku ezingu-30-45 zokukhiqiza

Inkokhelo

30% depsoit, 70% L/C noma B/L ikhophi noma 100% L/C lapho ubona