Ipayipi Lensimbi Elivunyiwe

Inkampani yethu igxile ekuthumeleni ipayipi lensimbi engenamthungoipayipi likathayela, Ipayipi Elivunyiwe Elingenamthungo, Ipayipi likathayela le-SMLS, Ipayipi likathayela elishiselwe.

Uyini umehluko phakathi kwamagalvanized ashisayo namakhaza?

I-Hot-dip galvanizing kanye nokubanda kwanika amandla umehluko:

1. Galvanizing, eyaziwa nangokuthi idiphu hot lashukumisa, nguye ingot elincibilikisiwe emazingeni okushisa aphezulu, inani lempahla eyengeziwe endaweni, ke wacwiliswa lashukumisa metal isakhiwo slot, ingxenye metal on ungqimba zinc enamathela . Izinzuzo ze-hot-dip galvanizing corrosion yekhono lakhe, ukunamathela kanye nobulukhuni be-zinc coating kungcono

"Cold plated" noma "plating", okungukuthi isixazululo zinc usawoti by electrolysis, ukuze Plating on enamathela, ngokuvamile abanalo Ukushisa, inani elincane zinc, imvelo emanzi kulula kakhulu ukuwa.

2. Idiphu elishisayo lifakwe ama-galvanized (galvanizing)

I-Hot-dip galvanizing iwukwelapha ngamakhemikhali, ukusabela kwe-electrochemical.

Cold galvanizing ikheli ngokomzimba, nje ukuxubha ungqimba ebusweni zinc, ungqimba zinc kulula ukuwa off. Ukwakhiwa ekusetshenzisweni kwe-hot dip galvanizing.

Inqubo eqhubekayo yokufaka amadiphu ashisayo: insimbi → ukufudumeza → ukupholisa izinga lokushisa ngama-galvanized → ukupholisa →

I-zinc ebandayo yama-galvanized ingu-10-50g/m2 kuphela, ukumelana nokugqwala kwayo kunediphu elishisayo elipheceleza umehluko omkhulu. Kukhanyiswe ngentengo eshibhe uma kuqhathaniswa.

I-hot dip galvanized steel body iyindawo eshisayo yediphu ngaphansi kwesimo sokunamathela kwayo eqinile, akulula ukuwa, nakuba kukhona idiphu elishisayo.ipayipi likathayelaukugqwala, kodwa esikhathini eside kakhulu ukuhlangabezana nezobuchwepheshe, izidingo zezempilo.

3. Ukwehluka kwezobuchwepheshe

Okokuqala, umehluko phakathi inqubo: hot-dip galvanizing iyona workpiece degreasing, pickling, ukucwilisa, omiswe ukucwiliswa liquid in ezincibilikisiwe zinc isikhathi esithile, ingavuswa.

Eyaziwa nangokuthi i-electro-galvanized cold galvanizing, iwukusebenzisa amadivaysi e-electrolysis workpiece ngokusebenzisa i-degreasing, izithako zokukhetha okuthunyelwe kusixazululo sikasawoti zinc, futhi uxhume imishini ye-anode electrolysis; endaweni yonkana izingxenye zepuleti le-zinc elixhunywe emshinini we-electrolysis omuhle, amandla avuliwe, ukusetshenziswa kwamandla kusukela ku-cathode kuya ku-anode yokunyakaza okuqondisayo kwe-workpiece kuzofakwa ungqimba lwe-zinc.

UZinc uqede umehluko: akukho okubandayo okucwebezelayo okucwebezelayo okucwebezelayo okucwebezelayo, kodwa ukujiya kocwecwe lwezinki lwezici ezibandayo zokucwebezelisa amadiphu ashisayo izikhathi ezimbalwa. Ukumelana nokugqwala kwe-galvanized nakho kuyizikhathi eziningana.

Uhlolojikelele

Isicelo

Isetshenziselwa Ikakhulukazi izingxenye zamandla nengcindezi, futhi ngenjongo evamile yamapayipi omusi, amanzi, igesi nomoya.

Ibanga Eliyinhloko

G.A, GR.B

Ingxenye Yekhemikhali

| Ibanga | Ingxenye %,≤ | ||||||||

| C | Mn | P | S | CuA | NiA | CrA | MoA | VA | |

| Uhlobo lwe-S (ipayipi elingenamthungo) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo lwe-E (Ipayipi elishiselwe ukumelana) | |||||||||

| G.A | 0.25B | 0.95 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| GR.B | 0.30C | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

| Uhlobo F (Ipayipi Elishiselwe Esithandweni) | |||||||||

| A | 0.30B | 1.20 | 0.05 | 0.045 | 0.40 | 0.40 | 0.40 | 0.15 | 0.08 |

A Isamba salezi zakhi ezinhlanu akufanele sibe ngaphezu kuka-1.00%.

B Kulokho kwehla ngo-0.01% kokuqukethwe okuphezulu kwekhabhoni, okuqukethwe okuphezulu kwe-manganese kuvunyelwe ukukhuphuka ngo-0.06%, kodwa umkhawulo angeke udlule u-1.35%.

C Ukwehla ngakunye ngo-0.01% kokuqukethwe kwekhabhoni ephezulu kuzovumela okuqukethwe okuphezulu kwe-manganese ukuthi kukhuphuke ngo-0.06%, kodwa umkhawulo akumele udlule u-1.65%.

Impahla Mechanical

| into | G.A | GR.B |

| amandla okubamba, ≥, psi [MPa] Amandla Okukhiqiza, ≥, psi [MPa] Gauge 2in.noma 50mm ubude | 48 000 [330]30 000 [205]A,B | 60 000 [415]35 000 [240]A,B |

A Ubude obuncane begeji engu-2in. (50mm) izonqunywa ngefomula elandelayo:

e=625000(1940)A0.2/U0.9

e = ubude obuncane begeji engu-2in. (50mm), iphesenti lifinyezwa ku-0.5% eseduze;

A = Ibalwa ngokuhambisana nobubanzi obushiwo bangaphandle beshubhu lokuzisholo noma ububanzi besampula obuqinile kanye nogqinsi olucacisiwe lodonga, futhi lazungezwa endaweni eseduze yesigaba esiphambanayo yesampula eqinile engu-0.01 in.2 (1 mm2), futhi Iqhathaniswa no-0.75in.2 (500mm2), kuye ngokuthi yikuphi okuncane.

U = amandla amancane aqinile abekiwe, i-psi (MPa).

B Ngokuhlanganiswa okuhlukahlukene kosayizi abahlukene bezibonelo zokuhlolwa kwe-tensile namandla anqunyiwe abekiwe, ubude obuncane obudingekayo buboniswa kuThebula X4.1 noma kuThebula X4.2, ngokuya ngokusebenza kwakho.

Isidingo Sokuhlola

Ukuhlolwa kwe-tensile, ukuhlolwa kokugoba, ukuhlolwa kwe-hydrostatic, ukuhlolwa kukagesi okungonakalisi kwama-welds.

Supply Amandla

Ikhono Lokuhlinzeka: Amathani angu-2000 Ngenyanga Ngebanga ngalinye le-ASTM A53/A53M-2012 Ipayipi Lensimbi

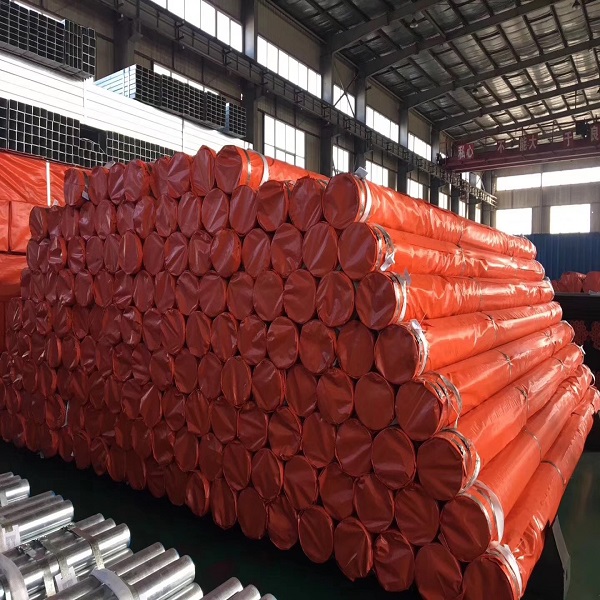

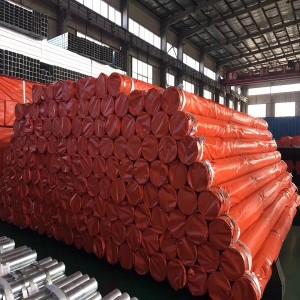

Ukupakisha

Kuyizinqwaba Nasebhokisini Lokhuni Eliqinile

Ukulethwa

Izinsuku ezingu-7-14 uma zisesitokweni, izinsuku ezingu-30-45 zokukhiqiza

Inkokhelo

30% depsoit, 70% L/C noma B/L ikhophi noma 100% L/C lapho ubona